A construction method for reconstruction and reinforcement of rock wool prefabricated houses

A prefabricated house and construction method technology, applied in the direction of buildings, building types, small buildings, etc., can solve problems such as unretrieved technical solutions, and achieve the effects of avoiding strong wind damage, being stable and environmentally friendly, and strengthening wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

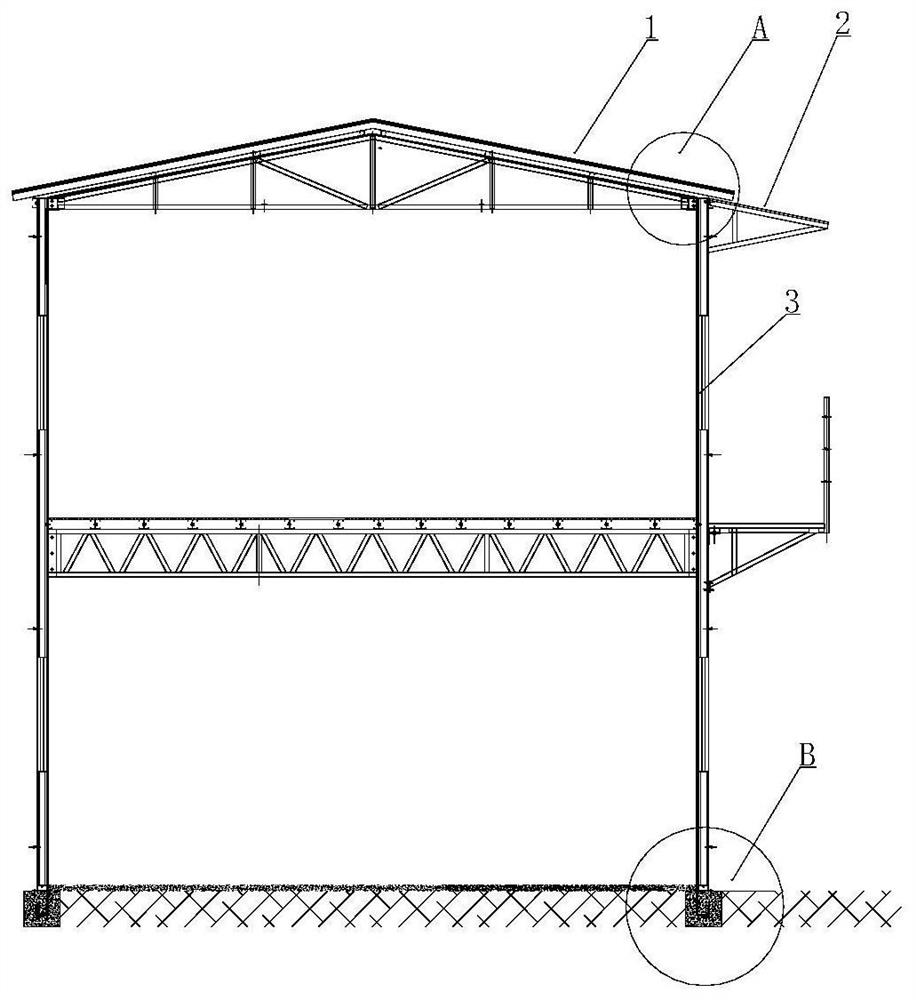

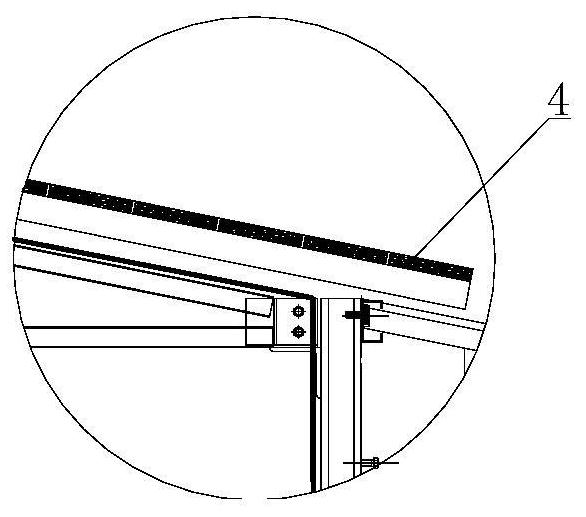

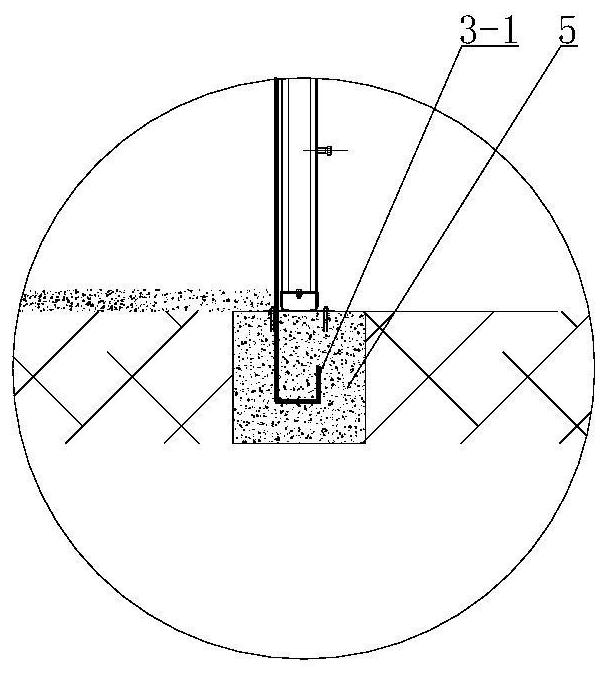

[0029] A kind of rebuilding reinforcement construction method of rock wool prefabricated house, please refer to Figure 1-5 , its invention point is, comprises following construction steps:

[0030] S1 In the weather without wind and rain, according to the technical standards and safety regulations stipulated by the state, two double-layer rock wool truss prefabricated houses were rebuilt on the original site, and the slope of the gable roof 1 was slowed down to reduce the height of the house , the slope is slowed down from the original 10% to 5%, and the extension length of the eaves 2 of the prefabricated house is reduced, and the extension length of the eaves is reduced from the original 600mm to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com