Cut tobacco processing resistance detection and characterization method based on image method

A technology of processing resistance and image method, which is applied in the field of processing resistance detection and characterization of cut tobacco based on the image method, can solve the problems of difficulty in sampling, affecting the processing process of cut tobacco, and achieves the effect of simple calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

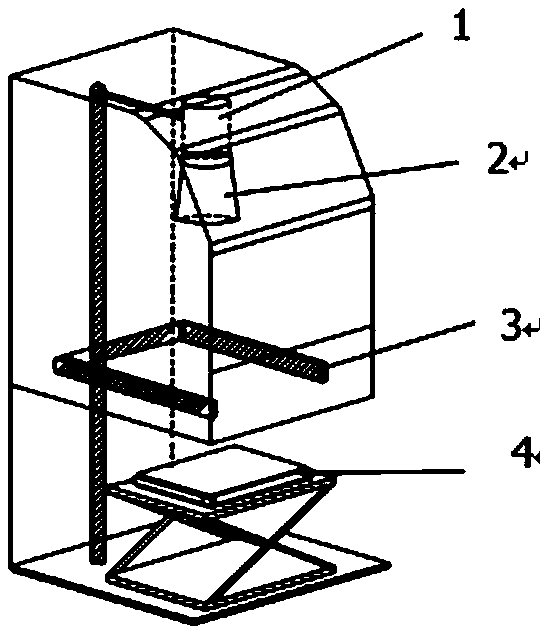

Method used

Image

Examples

Embodiment 1

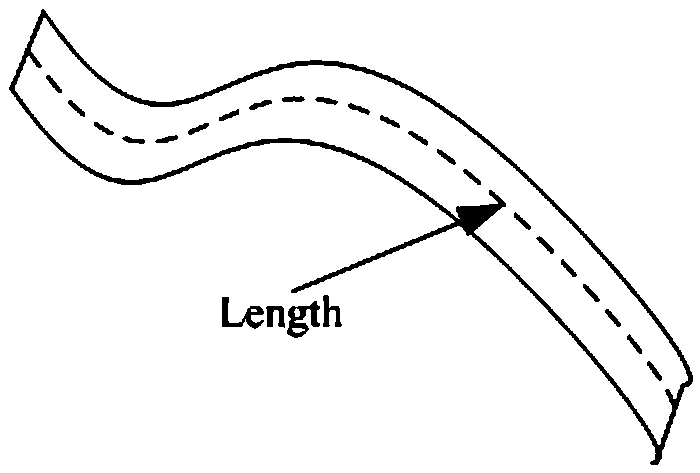

[0065] The same batch of shredded tobacco samples, from which 200g was sampled, was divided into 10 groups of 10g by quartering method after the shredded tobacco was balanced in moisture; Tobacco sample, and sample 200g from the medium, after the tobacco moisture balance, the sampled tobacco is divided into 10 groups with 10g in each group. Using the above-mentioned characterization method for the processing resistance of shredded tobacco, remove shredded tobacco whose width is less than 0.6 mm and whose length range is greater than the number average length ± 3б, and calculate the number average length L of each batch of shredded tobacco samples before air delivery 0a , Number average length L after air blowing 0b , Tobacco processing resistance shown in Table 1.

[0066] Table 1 Characterization results of processing resistance of shredded tobacco in air conveying process

[0067]

[0068] Also for this batch of shredded tobacco, sample 200g from it, after the shredded ...

Embodiment 2

[0073] The same batch of shredded tobacco samples, from which 200g is sampled, after the moisture balance of the shredded tobacco, divide the shredded tobacco into 10 groups, each group 15g; Sample, and sample 200g from the middle sample, cut tobacco is divided into 10 groups by quartering method after cutting tobacco moisture balance, each group is 15g. Using the above-mentioned characterization method for the processing resistance of shredded tobacco, cut shredded tobacco whose width is less than 0.6 mm and whose length range is greater than the number average length ± 3б is excluded, and the average length L of shredded tobacco before drum drying of each batch of samples is counted 0c 、Number-average length after drum drying L 0d , Tobacco processing resistance is shown in Table 3.

[0074] Table 3 Characterization results of processing resistance of shredded tobacco in air delivery process

[0075]

[0076] Also for this batch of shredded tobacco, sample 200g from it,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com