A device for online regulation of leaf silk structure

The technology of leaf silk and belt conveyor is applied in the field of tobacco processing technology, which can solve the problems of high maintenance and use costs, increase the end content rate of the leaf silk, increase the consumption of raw materials, etc., so as to achieve low manufacturing cost and eliminate excessive long leaf silk. , the effect of high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

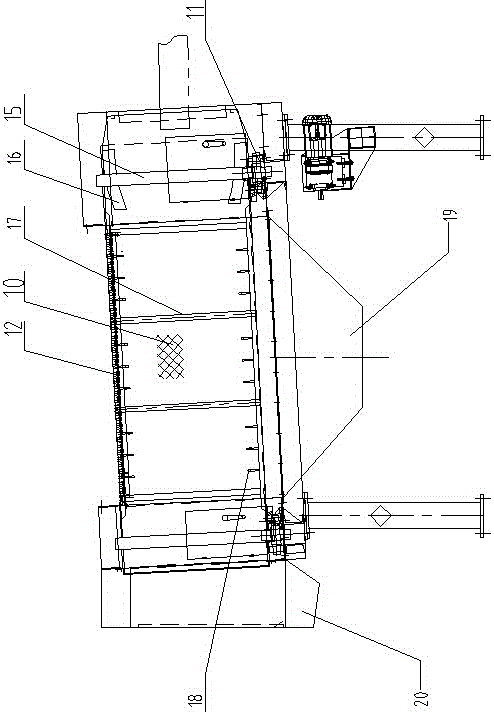

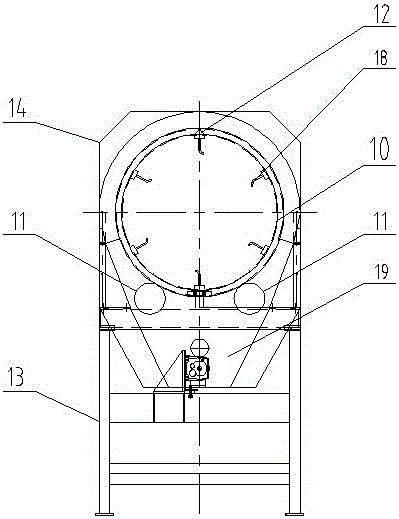

Embodiment Construction

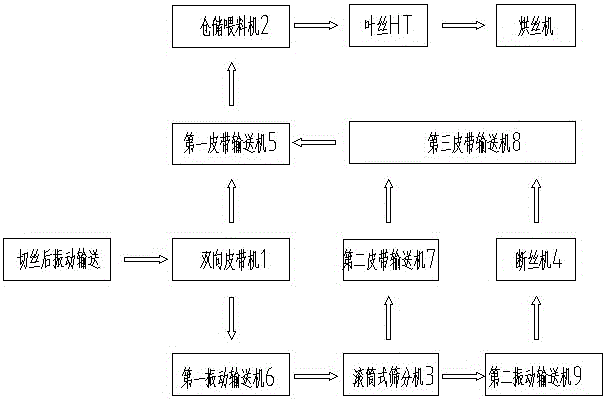

[0033] A processing technology using a device for on-line regulation of leaf silk structure, the technology includes:

[0034] (a) First, judge whether the length uniformity of shredded leaves is good or not by manual inspection. The standard for good uniformity of shredded leaf length is: the proportion of shredded leaves with a length of 2-4mm is ≥ 50%, and the proportion of shredded leaves with a length greater than 10mm is less than 1%. Leaf shredded rate≤3%;

[0035] (b) If the length uniformity of the shredded leaf is good, the shredded leaf is directly baked by the storage feeder 2;

[0036] (c) If the shredded leaves do not meet the requirements, the shredded leafs are first screened by the drum sieving machine 3, and the shredded leaves with a length greater than 5mm are separated;

[0037] (d) The shredded leaves with a length greater than 5mm are broken through the wire cutter 4, and then mixed evenly with the shredded leaves with a length less than 5mm and then ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com