Lyocell fiber bamboo pulp and preparation method thereof

A bamboo pulp and fiber technology, applied in the direction of non-fibrous pulp addition, cellulose pulp post-treatment, fiber raw materials, etc., can solve the problems of limited wood resources, high pentosan content, high cost, etc., to improve the uniformity of polymerization degree , reduce the content of pentosan, improve the effect of cooking uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

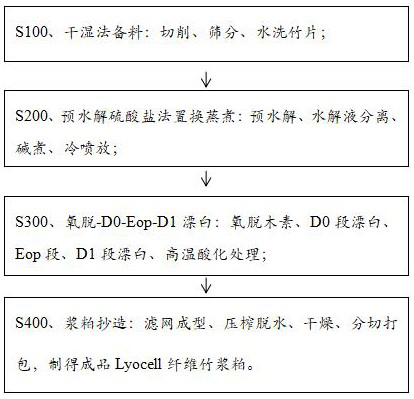

[0037] like figure 1 Shown, present embodiment provides a kind of preparation method of Lyocell fiber bamboo pulp, comprises the following steps:

[0038] S100, wet and dry method of material preparation

[0039] S110, cutting: cutting bamboo to form a mixture of bamboo flakes, bamboo strips, bamboo knots and bamboo ash;

[0040] S120. Screening: There is a big difference in cell structure and morphology between bamboo nodes and internode tissues. Internode tissues are rich in elongated fiber cells, while bamboo nodes are mainly short fibers and miscellaneous cells. Bamboo pulp production technology is to crush the bamboo joints, and then cook together with the internode tissue, resulting in a large dispersion of the bamboo pulp polymerization degree, so this embodiment uses a disc sieve and a swing sieve to sieve the mixture in step S110 , sieve out 20-60mm bamboo slices for later use, and sieve out bamboo sticks, bamboo joints and bamboo ash for other uses. After screening...

Embodiment 2

[0059] A kind of Lyocell fiber bamboo pulp, adopt the preparation method of the Lyocell fiber bamboo pulp of embodiment 1 to make, the whiteness of Lyocell fiber bamboo pulp>87%, pentosan<3.0%, ash<0.08%, iron content <10ppm, degree of polymerization 430-470DP.

[0060] One of the specific embodiments is:

[0061] S100, wet and dry method of material preparation

[0062] S110, cutting: cutting bamboo to form a mixture of bamboo flakes, bamboo strips, bamboo knots and bamboo ash;

[0063] S120, sieving: Utilize disc sieve and swing sieve to sieve the mixture in step S110, sieve out the bamboo chips of 20-60mm for later use, and sieve out bamboo strips, bamboo joints and bamboo ash for other purposes, and the size is qualified after sieving The weight percentage of bamboo chips is 80.1%, and the weight percentage of bamboo joints is 2.0%;

[0064] S120. Washing bamboo slices: Use inclined plate sedimentation tanks to process the washing water for recycling. The pH value of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com