A kind of method of combed cotton type ramie spinning

A technology for combing cotton and ramie, applied in the field of ramie spinning preparation, can solve the burden of affecting the quality of the ramie yarn in the subsequent spinning process of the drawing and cutting process, affecting the quality of the yarn, the smooth progress of the spinning process, and the burden of drawing and cutting. It can improve the spinning efficiency, improve the yarn quality, and reduce the burden of drawing and cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The length of fiber in the ramie strip is stretched and cut into about 30mm.

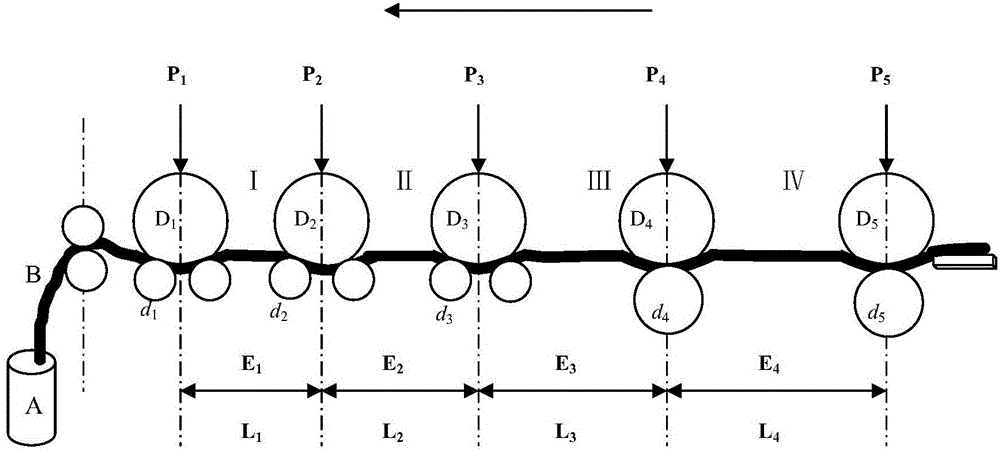

[0026] In this embodiment, the ramie refined dry hemp is subjected to opening, combing, pre-combing, combing, needle combing, and stretching, wherein such as figure 1 As shown, it is a schematic diagram of the stretching mechanism of the stretching process of the present invention, and its mechanism is divided into four areas: I and II areas belong to the stretching area, and III and IV areas belong to the drafting area. The sliver first enters the pre- and main drafting zones (zones Ⅳ and Ⅲ), where the roller pressure and drafting ratio are relatively small, and the parallel straightness of the fibers is improved to prepare for the subsequent drafting. Then the sliver enters the pre-stretching zone (Zone II), and some fibers whose length is greater than the interval of this zone are broken. When the hemp sliver enters the main draft cutting zone (zone Ⅰ), the fiber is gradually broken into...

Embodiment 2

[0031] The length of the fiber in the ramie strip is drawn into about 40mm.

[0032] In this embodiment, the same ramie fine dry hemp is subjected to opening, combing, pre-combing, combing, needle combing, and stretch cutting, wherein the stretch cutting mechanism is the same as that of Example 1, and the main stretch cutting area is separated by L 1 40mm, pre-stretching zone distance L 2 80mm, the main draft zone distance L 3 120mm, pre-drawing zone distance L 4 is 160mm; the traction and cutting machine adopts pneumatic pressure, and its pressure distribution is P 1 215kg, P 2 215kg, P 3 215kg, P 4 135kg, P 5 135kg; multiples E of the main stretch area 1 3, the multiple E of the pre-stretching area 2 is 1.7, and the drafting multiple E of the main drafting zone 3 is 1.35, and the drafting ratio E in the pre-drawing zone 4 is 1.25.

[0033] The stretch-cut ramie strips are directly drawn, roved and spun on the cotton spinning equipment.

[0034] The holding distan...

Embodiment 3

[0036] The length of the fiber in the ramie strip is stretched and cut into about 50mm.

[0037] In this embodiment, the same ramie fine dry hemp is subjected to opening, combing, pre-combing, combing, needle combing, and stretch cutting, wherein the stretch cutting mechanism is the same as that of Example 1, and the main stretch cutting area is separated by L 1 50mm, pre-stretching zone distance L 2 is 100mm, and the distance L of the main drafting zone 3 150mm, pre-stretching zone distance L 4 is 200mm; the multiple E of the main stretch area 1 2, the multiple E of the pre-stretch area 2 1.7; the first top roller pressure P 1 205kg, the second top roller presses P 2 For 205kg, the third top roller is pressurized P 3 For 205kg, the fourth top roller is pressurized P 4 For 127kg, the fifth top roller is pressurized P 5 It is 127kg;, the draft cut multiple E in the main draft zone 3 is 1.1, and the drafting ratio E in the pre-drawing zone 4 is 1.17.

[0038] The stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com