Shielded metal arc welding system and welding power supply for shielded metal arc welding

A technology of arc welding and welding power supply, which is applied in the direction of arc welding equipment, welding medium, welding equipment, etc. It can solve the problems of low power factor and low phase power factor, and achieve the effect of high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Preferred embodiments of the present invention will be specifically described below with reference to the drawings.

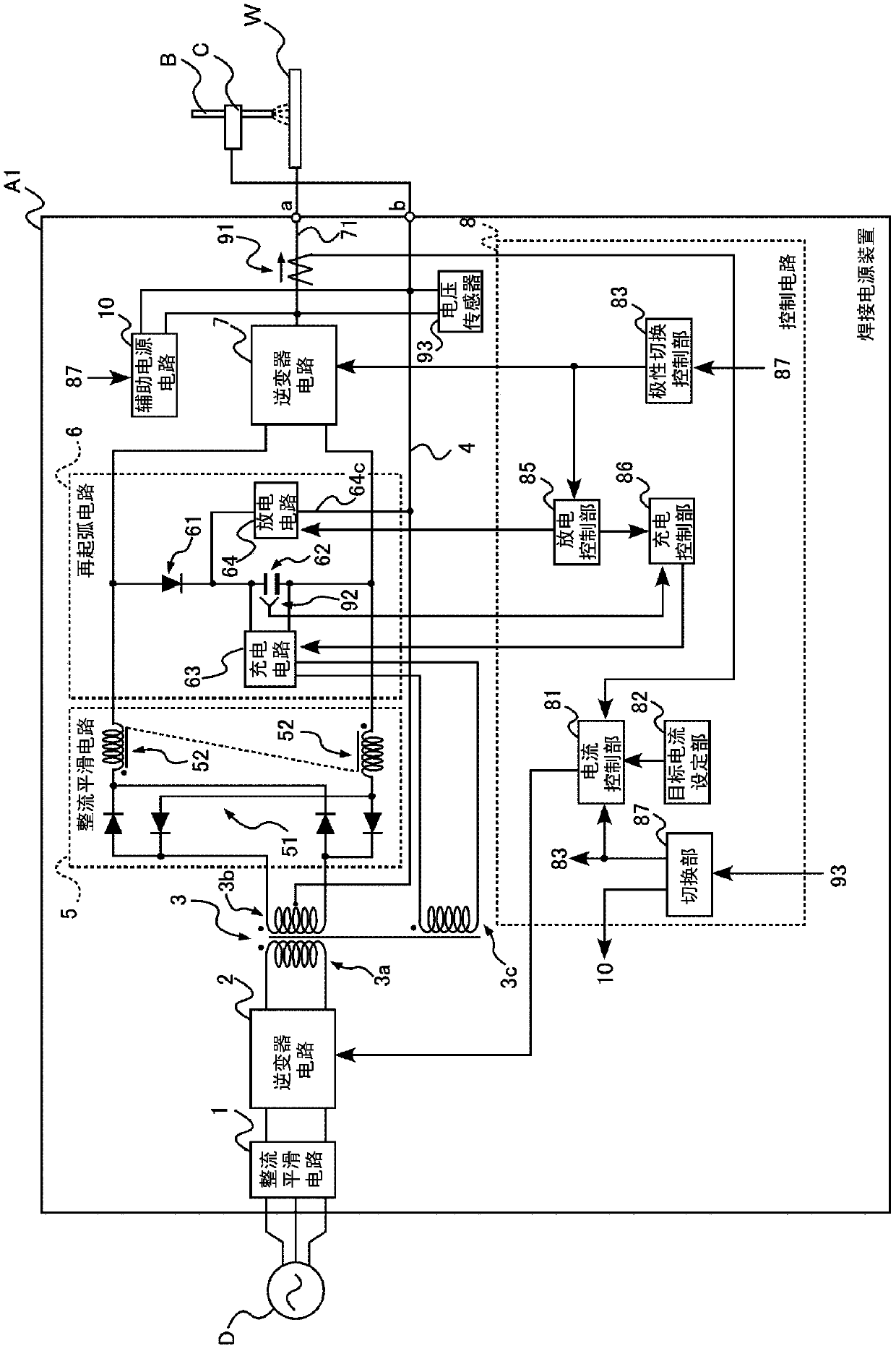

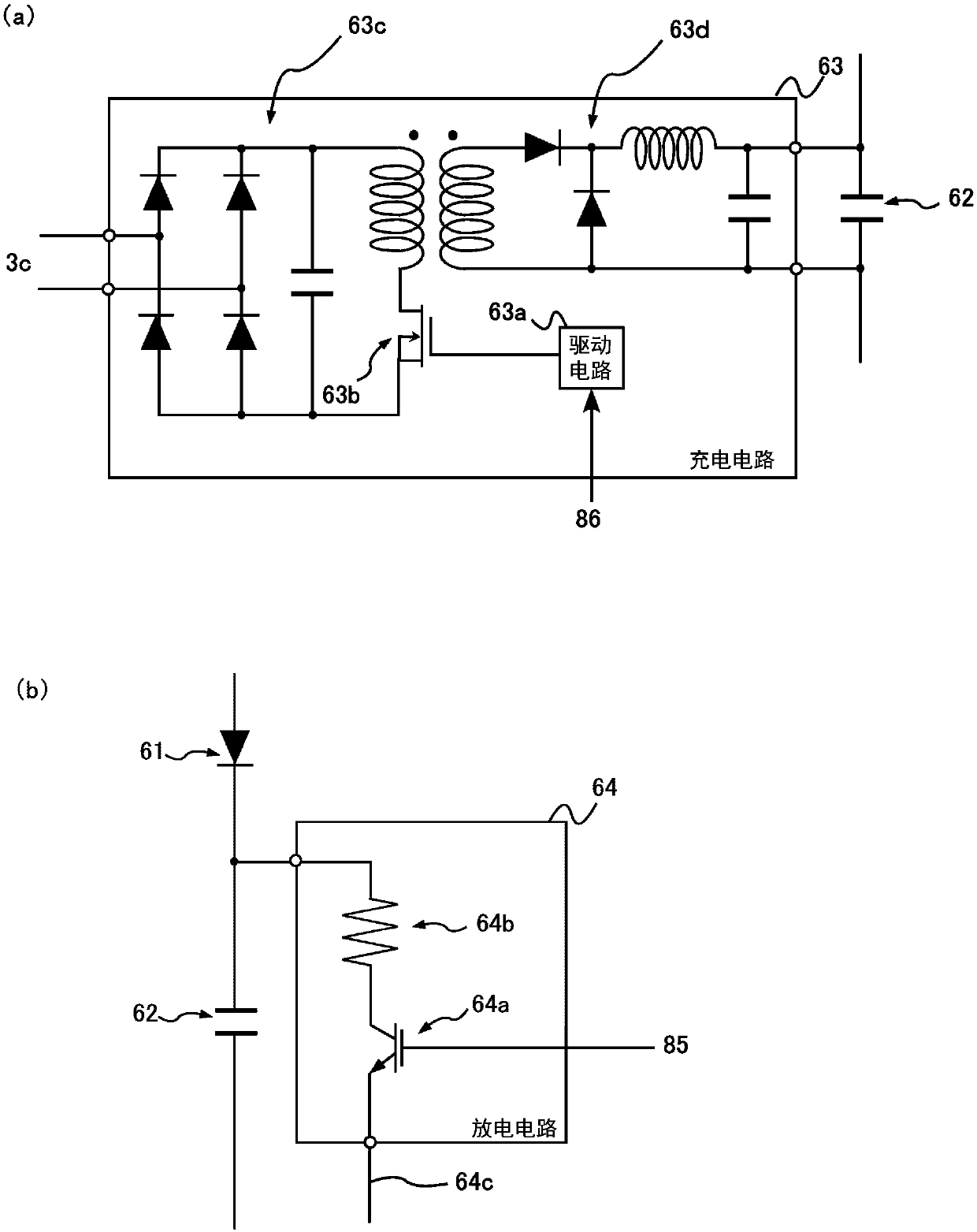

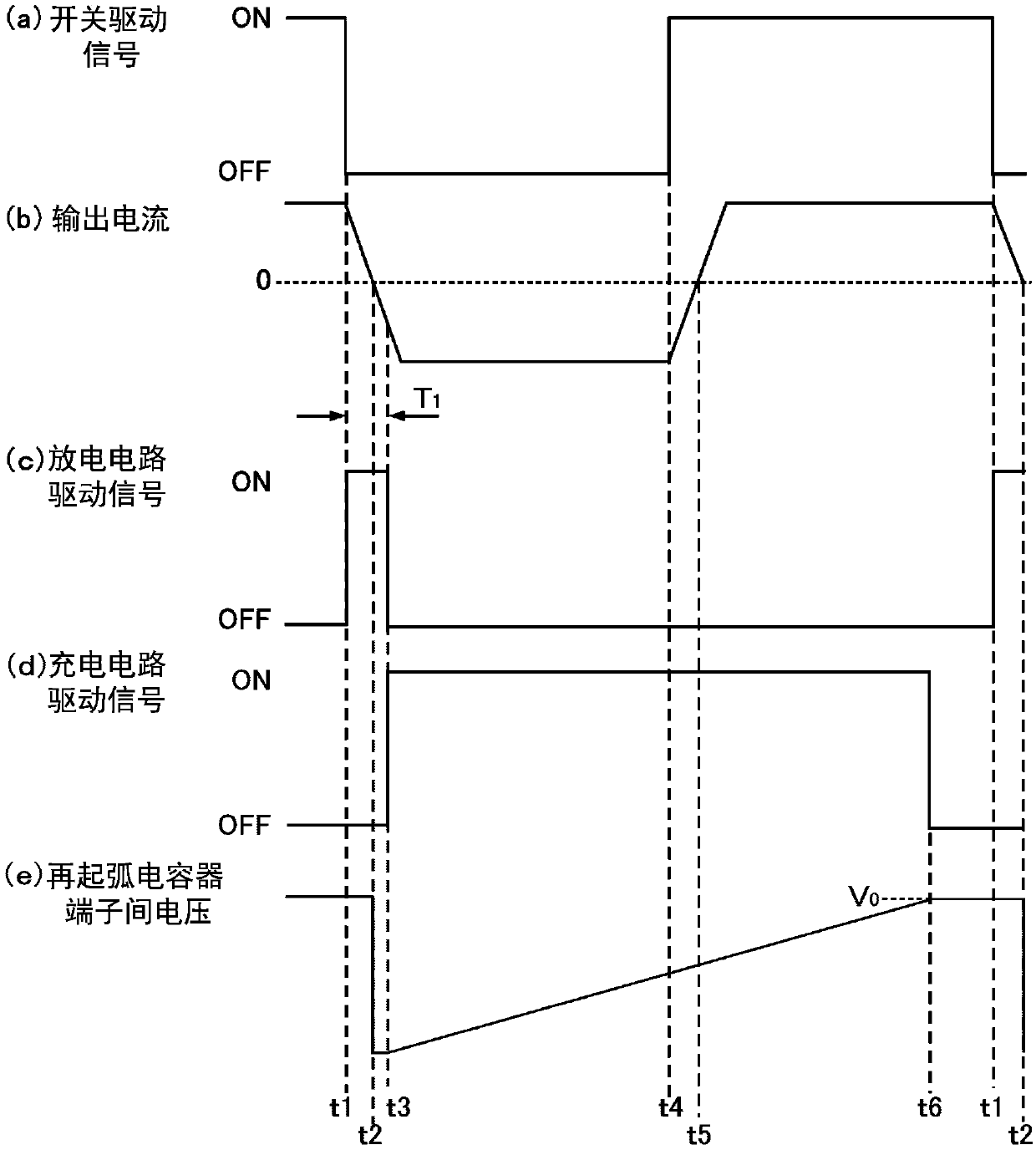

[0072] Figure 1 to Figure 4 It is a figure for demonstrating the covered arc welding system concerning 1st Embodiment. figure 1 It is a block diagram showing the internal structure of the welding power source apparatus A1 which concerns on 1st Embodiment, and shows the whole structure of a covered arc welding system. figure 2 (a) is a circuit diagram which shows an example of the charging circuit 63 of welding power source apparatus A1. figure 2 (b) is a circuit diagram which shows an example of the discharge circuit 64 of welding power supply apparatus A1. image 3 It is a timing chart for explaining the control of the restriking circuit 6, and shows the waveform of each signal of the welding power supply unit A1. Figure 4 It is a waveform diagram showing the waveform of the input current of the welding power supply device according to the first...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap