Mold stripping ejector pin limitation ejection mechanism

A technology of ejector mechanism and thimble, which is applied in the field of mold ejection ejector pin limit ejection mechanism, which can solve the problems of low production efficiency and the inability of products to fall off automatically, and achieve the effects of reducing labor, saving costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

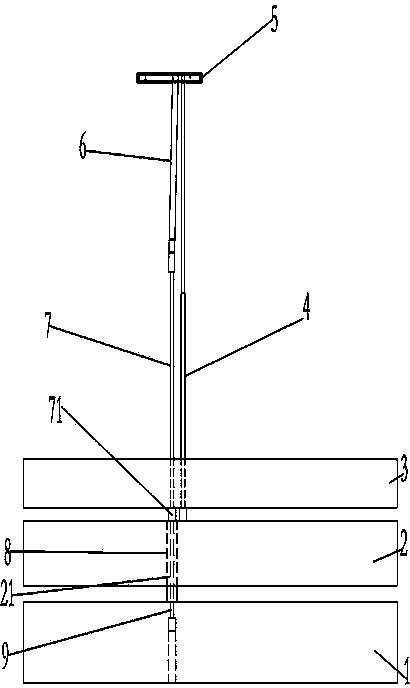

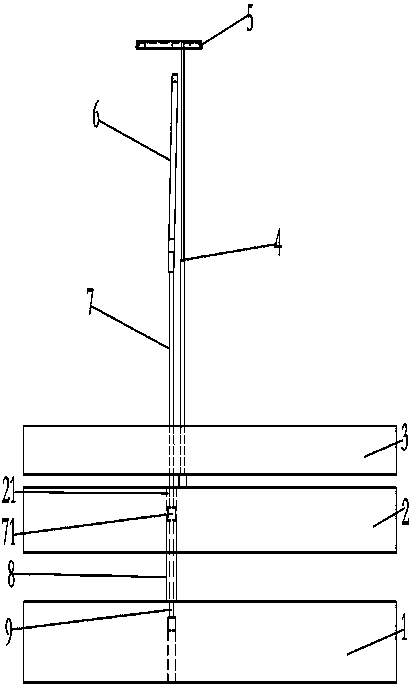

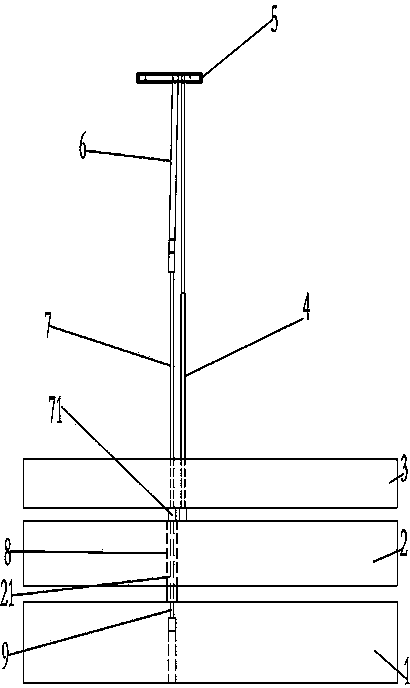

[0009] see Figure 1-Figure 2 , a ejector pin limit ejection mechanism for mold ejection, including ejector pin 7, inclined ejector 6, spring 8 and insert pin 9, inclined ejector 6 is connected to the top of ejector pin 7, insert spring 8 is sleeved on insert pin 9, and the upper end of spring 8 is ejected With the cup head 71 of the thimble 7, the diameter of the via hole 21 of the spring 8 on the thimble base plate 2 is greater than the diameter of the cup head 71. There is also another thimble 4, thimble panel 3, thimble bottom plate 2 and lower fixing plate 1 in the mold, which are used for injection molding products 5.

[0010] When ejecting, use the preload of the spring 8 to push the thimble 7 and the inclined ejector 6 out for a certain distance (the rubber position of the ejected product 5), the spring 8 returns to the original length, and the spring hole 21 on the ejector base 2 Diameter is greater than the diameter of the cup head 71 of thimble 7, and thimble 7 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com