Method and device for comprehensive measurement of shape and performance parameters of laser confocal nuclear fusion target pellet

A technology for comprehensive measurement and fusion targets, applied in measurement devices, optical devices, material excitation analysis, etc., can solve problems such as damage to the target, low efficiency, and inability to fully reveal the phenomenon and laws of the structural changes of the target. The effect of attribute differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

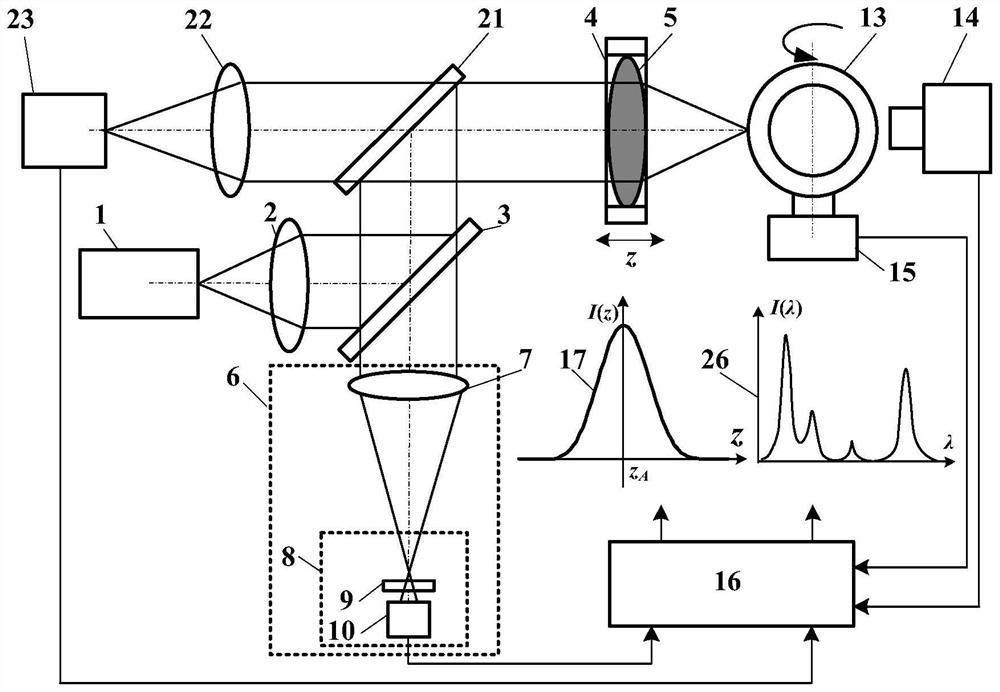

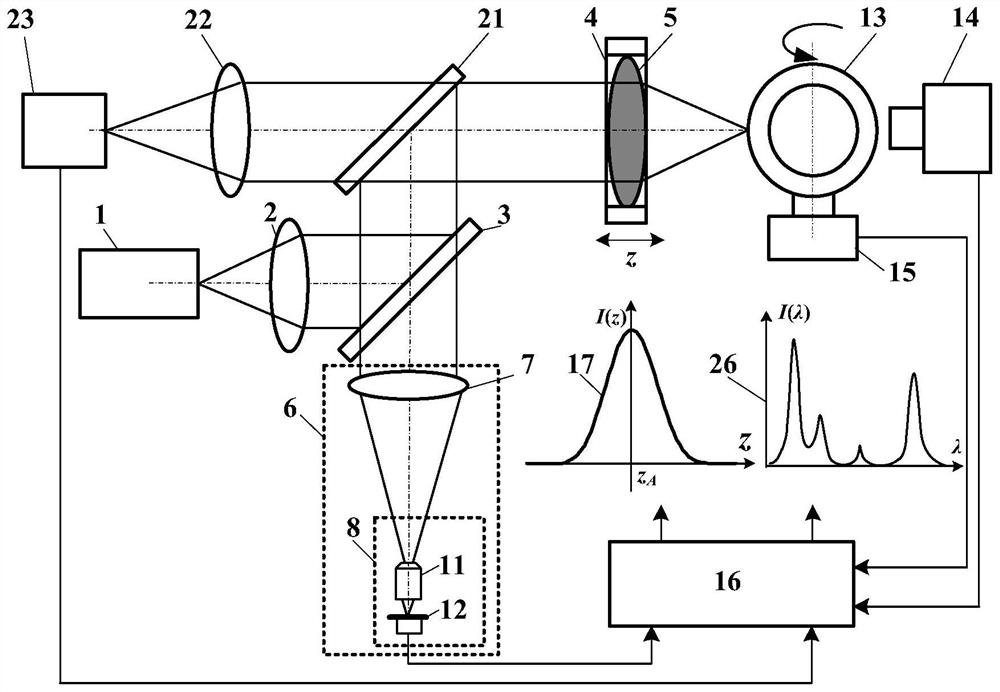

[0053] like image 3 As shown, in the comprehensive measurement method of the morphological performance parameters of the laser confocal nuclear fusion target, the light source system 1 selects a point light source, and the divergent beam emitted by the point light source is collimated into a parallel beam through the collimating lens 2, and the parallel beam is reflected by the beam splitter 3. It is again reflected by the dichroic beam splitter 21 to form a reflected illumination beam. The reflected illumination beam is converged by the measurement objective 5 into a point to illuminate the fusion target 13. The illumination light is reflected by the fusion target 13 and excited to generate a Raman spectrum, which carries the fusion target. The Raman spectrum and the reflected beam of the information of the pill 13 pass through the measurement objective lens 5 to form a measurement beam, and the Raman spectrum in the measurement beam passes through the dichroic beam splitter ...

Embodiment 2

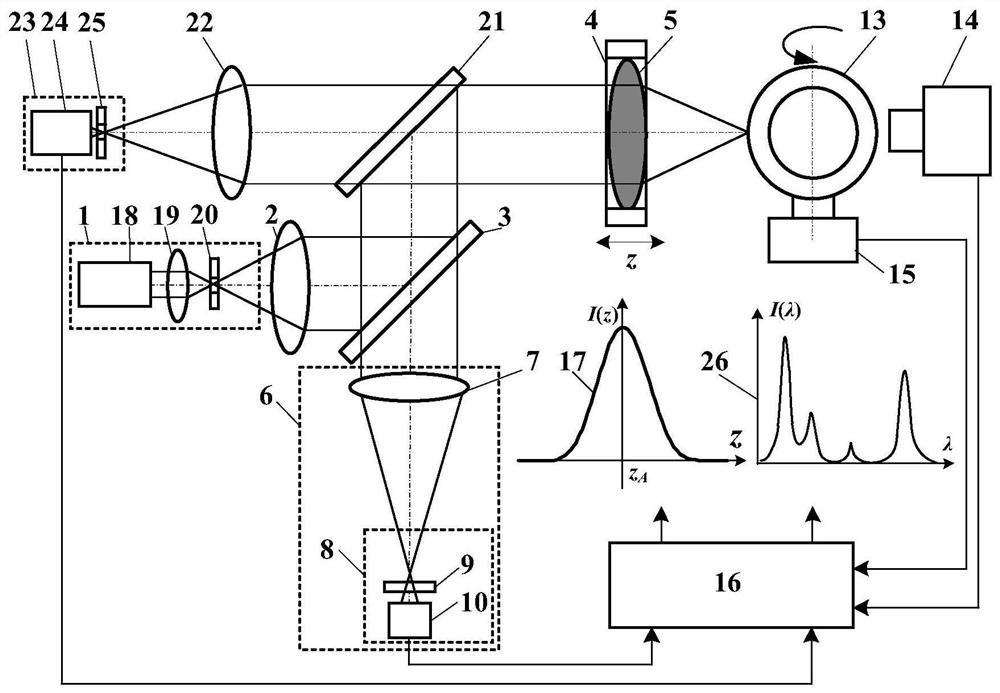

[0067] like Figure 4 As shown in the figure, the comprehensive measurement device for the shape and performance parameters of the laser confocal nuclear fusion target includes a light source system 1, a beam splitter 3 placed along the exit direction of the light source, and a dichroic beam splitter 21 placed along the reflection direction of the beam splitter 3. The measurement objective lens 5 is placed in sequence along the reflection direction of the dichroic beam splitter 21, the confocal detection system 6 is located in the opposite direction of the reflection direction of the beam splitter 3, and the spectral converging mirror 22 is placed in the opposite direction of the reflection direction of the dichroic beam splitter 21. And the spectral detection system 23, the orthogonal drive system 14 which is located in the outgoing direction of the measurement objective lens 5 and the rotation axis is coaxial with the measurement optical axis, the rotation drive system 15 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com