Ironing apparatus comprising a steam bypass circuit

A technology of ironing equipment and steam flow, which is applied in the direction of hand irons, washing devices, textiles and papermaking, etc., and can solve the problems of reduced performance of irons, reduced evaporation flow of steam distribution circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

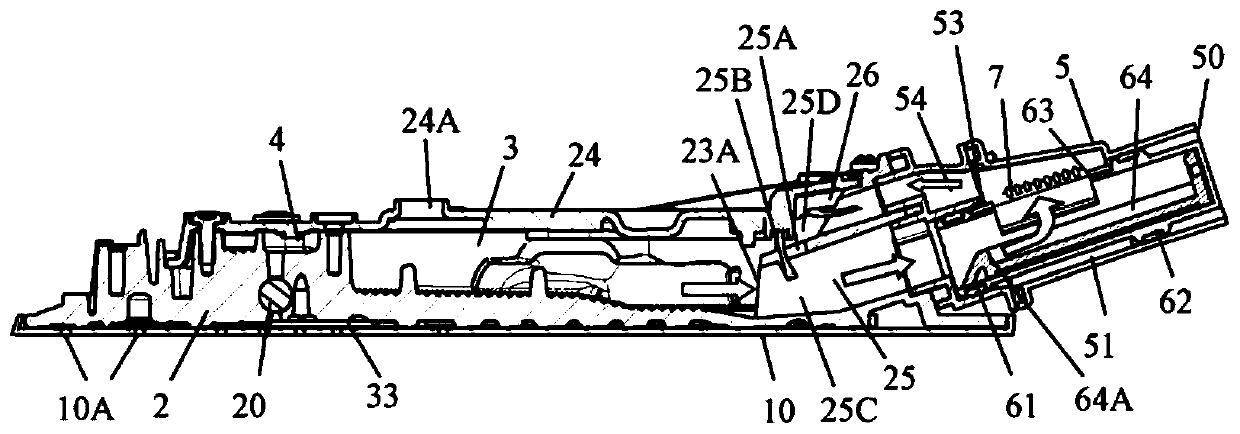

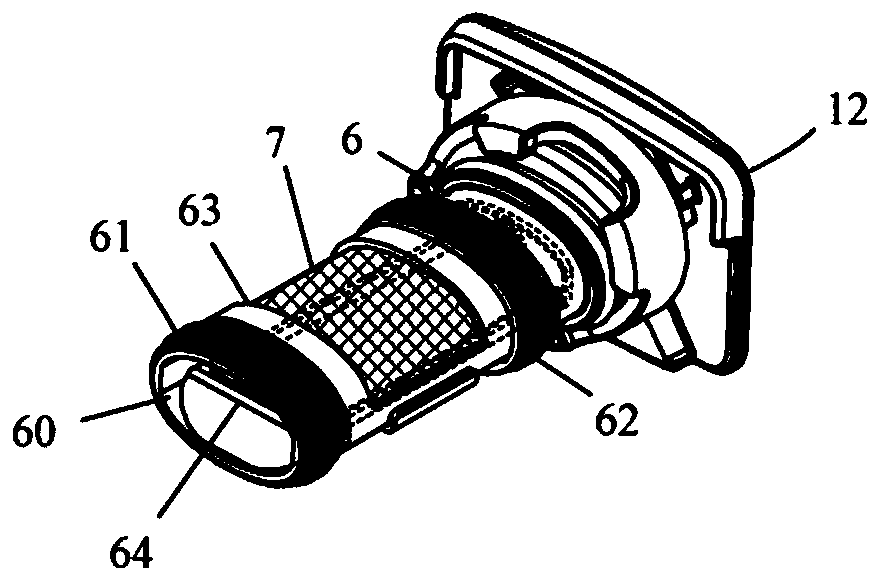

[0055] Only elements necessary for understanding the invention are shown. For ease of reading the drawings, identical elements between different drawings have the same reference numerals.

[0056] It should be noted that in this document the terms "horizontal", "vertical", "lower", "upper", "front", "rear" are used to describe an iron with reference to The situation at the time.

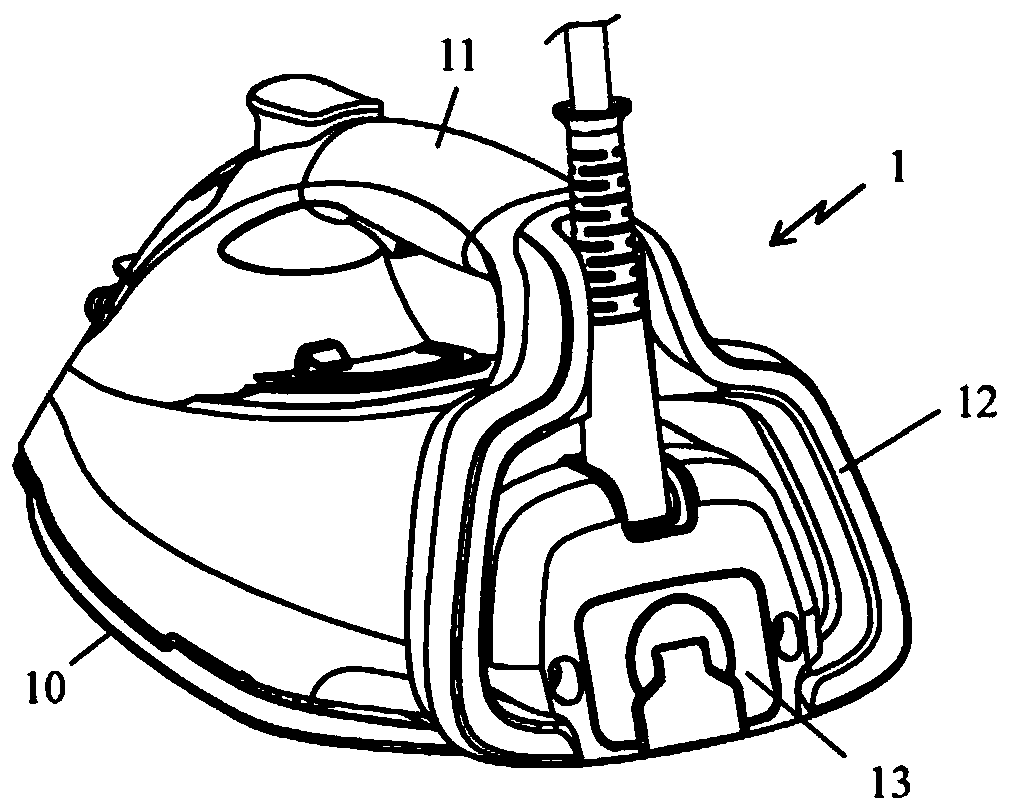

[0057] figure 1 Shown is an ironing appliance consisting of a steam iron 1 comprising an ironing soleplate 10 equipped with a set of steam outlet holes 10A, such as figure 2 shown. The soleplate 10 is topped by a plastic casing comprising a grip handle 11 at its upper end and a base 12 in its rear, on which the iron can be placed approximately vertically during the inoperative phase of ironing. on the base 12.

[0058] The base 12 comprises two arms that delimit between each other a space that accommodates a removable plug 13 that provides access to a scale drain hole 50, as figure 2 shown. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap