Pipeline ray flaw detection device and flaw detection method

A technology of ray flaw detection and ray flaw detector, which is applied to measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of different distances and angles, inconvenient measurement, etc., and achieve a wide range of applications and improve the effect of flaw detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

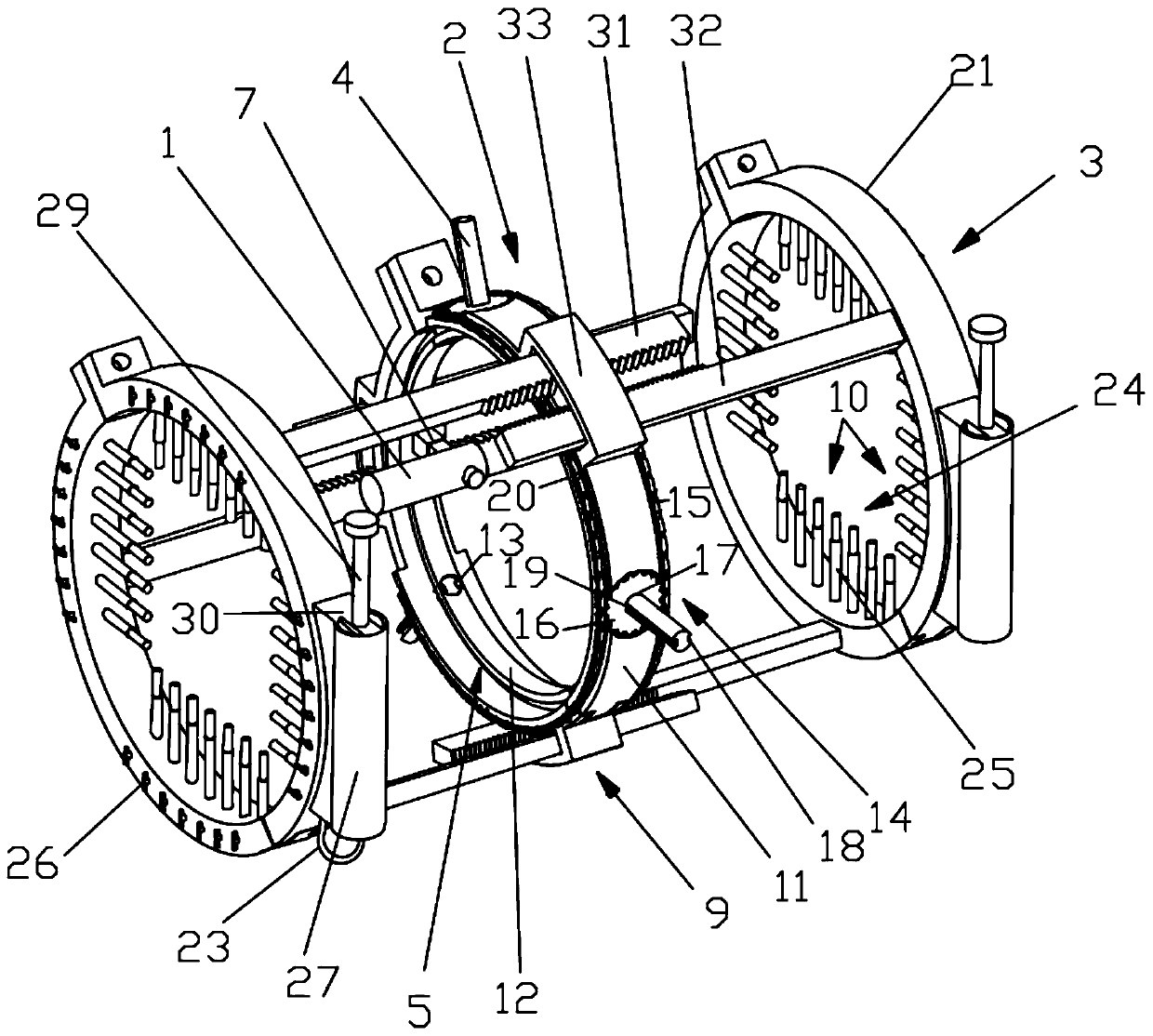

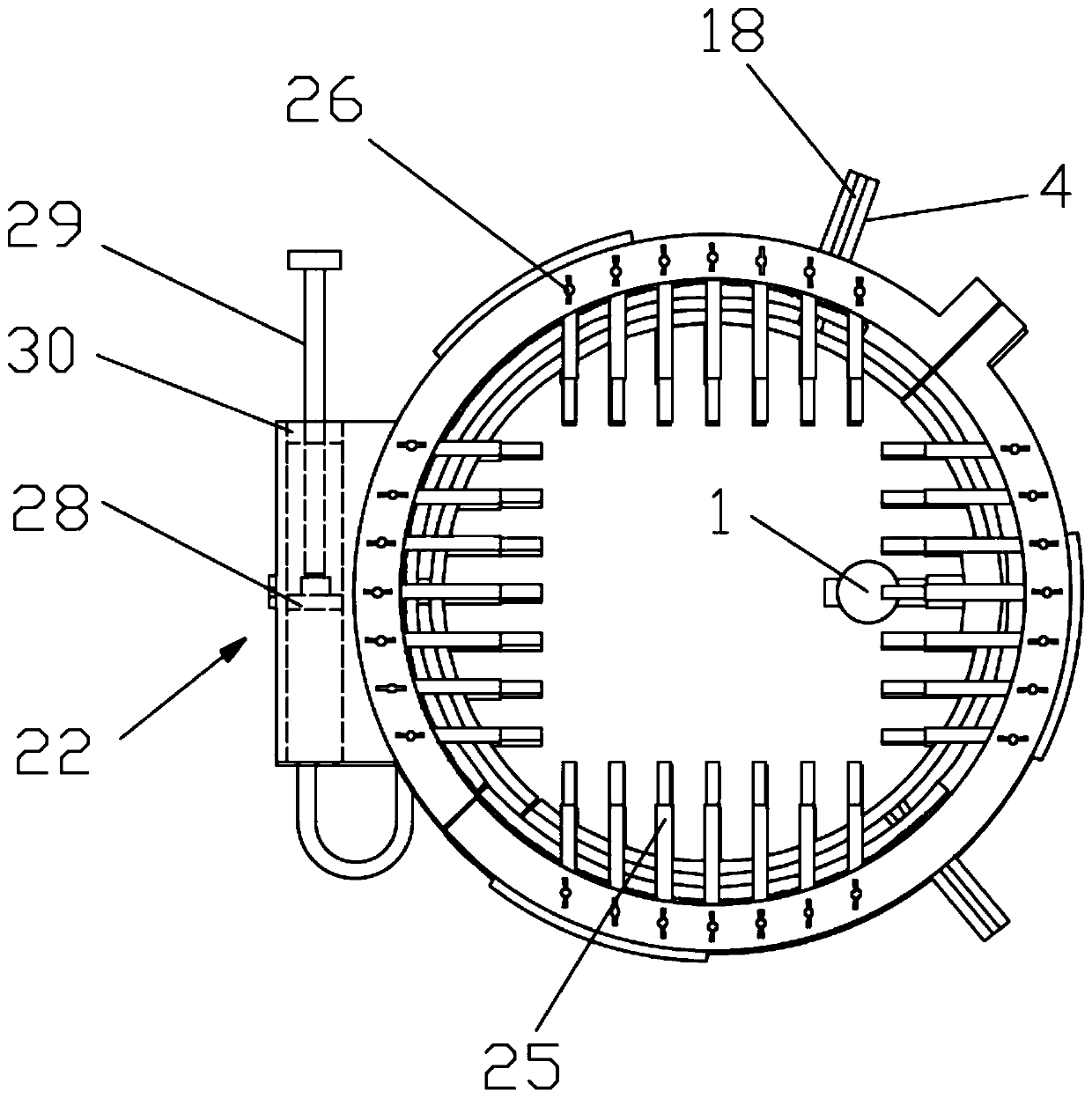

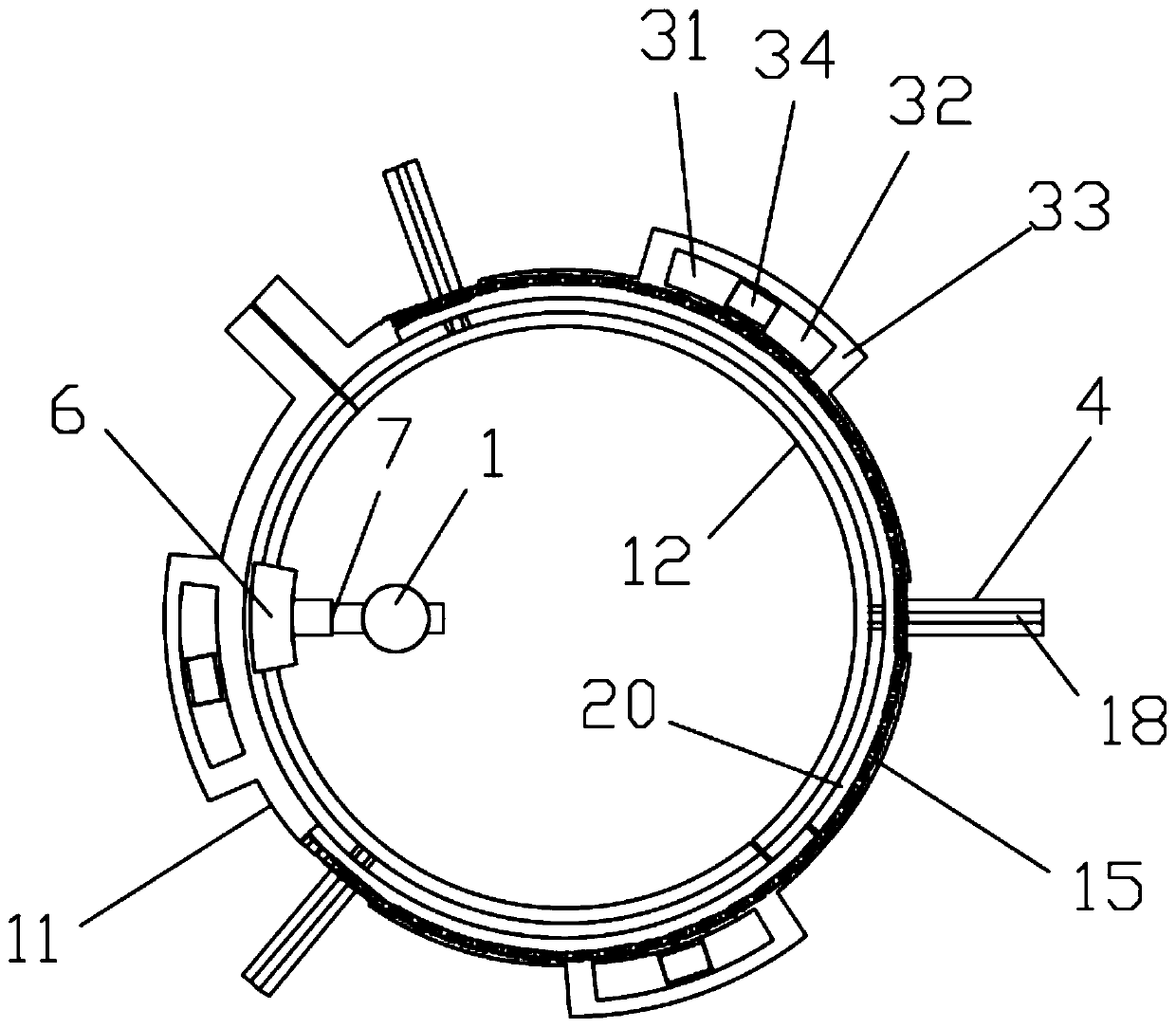

[0027] see Figures 1 to 4 , a pipeline radiographic flaw detection device, including a radiographic flaw detector 1, a positioning ring 2 and at least two fixing rings 3, the positioning ring 2 is provided with a plurality of positioning rods 4, and the positioning rods 4 and the positioning ring 2 are movably connected It is used to fix the welding seam in the middle of the positioning ring 2. The positioning ring 2 is provided with a ring slide rail 5, and a slide block 6 is provided on the ring slide rail 5. The slide block 6 passes through the telescopic rod 7 and the radiographic inspection The instrument 1 is fixedly connected, the fixed ring 3 is located on both sides of the positioning ring 2, and is connected with the positioning ring 2 through a linkage mechanism 9, and the fixed ring 3 is provided with a fixing ring for fixing itself on the pipeline. Fix the assembly 10.

[0028] Pass the pipe through the fixed ring 3 and the positioning ring 2, so that the plane ...

Embodiment 2

[0032] see Figures 1 to 4 , The difference between this embodiment and Embodiment 1 is that the positioning ring 2 is provided with a first threaded hole 13, and the positioning rod 4 is provided with a thread matched with the first threaded hole 13, and the positioning rod 4 passes through The transmission mechanisms 14 are mutually driven to rotate. Positioning rod 4 is provided with screw thread, and thread and threaded hole cooperate mutually, and positioning rod 4 is screwed into the center of positioning ring 2 when rotating positioning rod 4. The positioning rods 4 are mutually driven and rotated by the transmission mechanism 14. When one of the positioning rods 4 is rotated, the remaining positioning rods 4 rotate synchronously, and move and screw into the center of the positioning ring 2 to ensure that the welding seam is located in the middle of the positioning ring 2 without repeated adjustment. The depth to which each positioning rod 4 is screwed in.

[0033] Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com