Display panel and display device

A technology for display panels and display devices, applied in instruments, nonlinear optics, optics, etc., can solve the problems of poor intelligence and poor accuracy of measurement results, and achieve the effect of improving intelligence and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

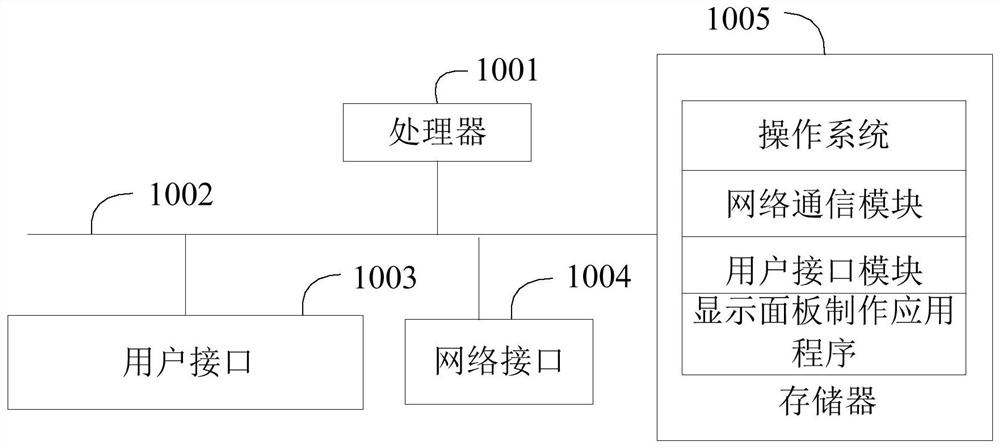

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

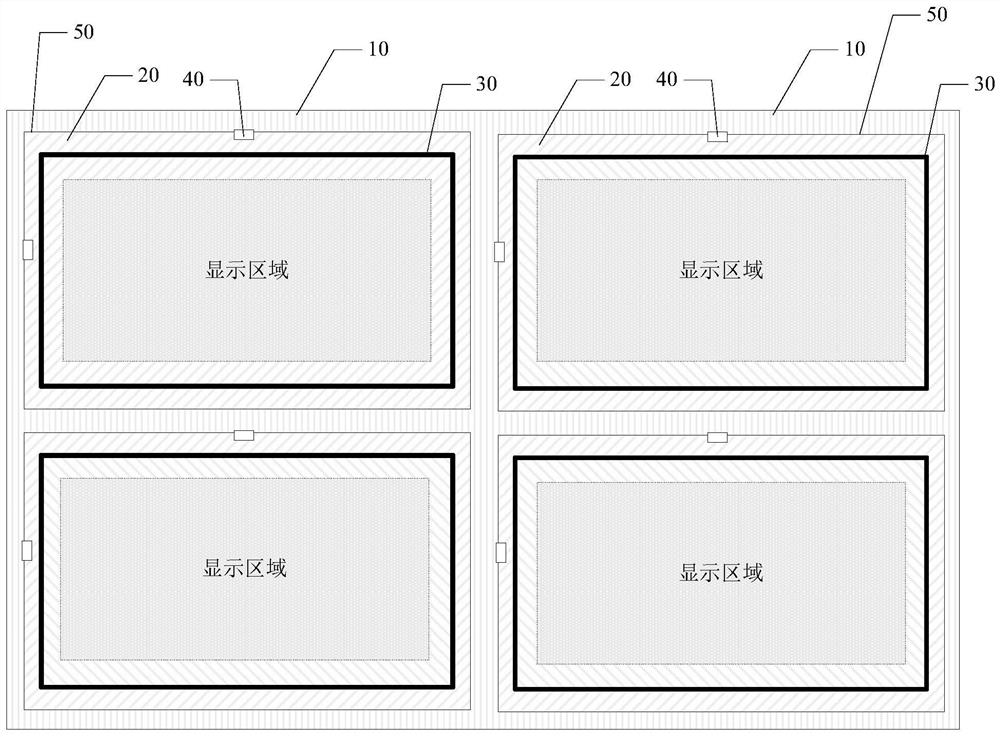

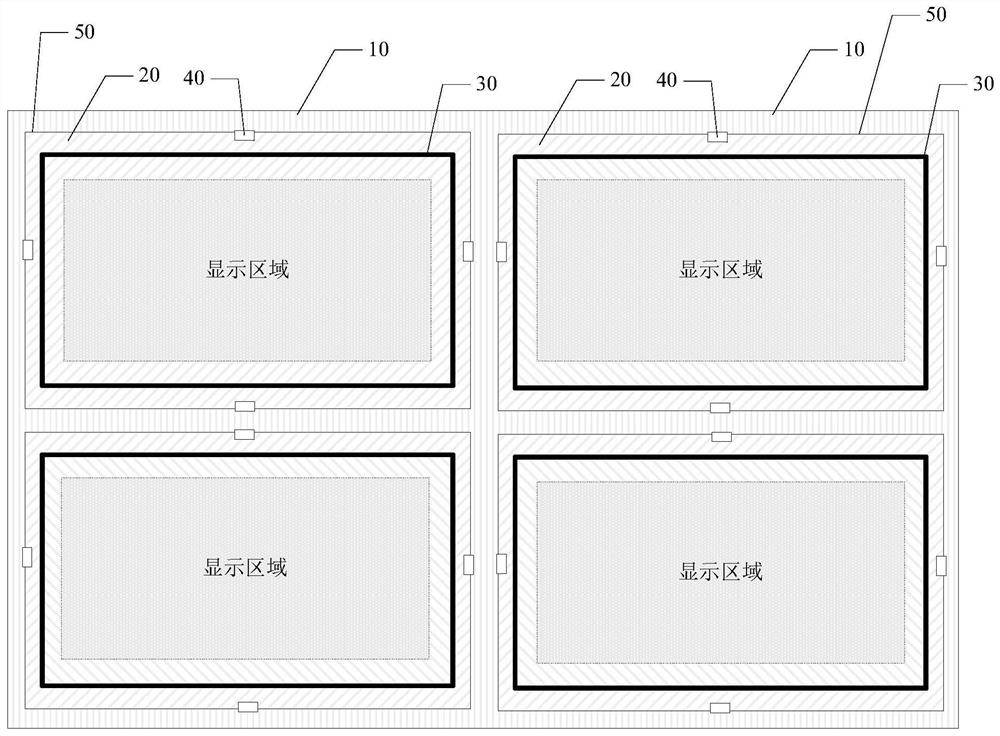

[0037] The main solutions of the embodiments of the present invention are: a substrate, including a plurality of sub-display substrates arranged in a matrix; a frame sealant, arranged around the display area of the sub-display substrate; a mark, the mark is arranged on the sealing frame Outside the area where the glue is located, the distance between the mark and the frame-sealing glue is a preset distance, so that the measuring device grabs the mark and moves to measure the width of the frame-sealing glue.

[0038] Due to the current manual operation to measure the width of the frame sealant, the accuracy of the measurement results is poor and the degree of intelligence is poor. The present invention provides a solution, which realizes the measurement of the sealant by marking, because the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com