Installation trailer for coiled flexible pipe and method of utilizing same

A trailer and coil technology, applied in the field of trailer frame and coil system, can solve the problem of large tube coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

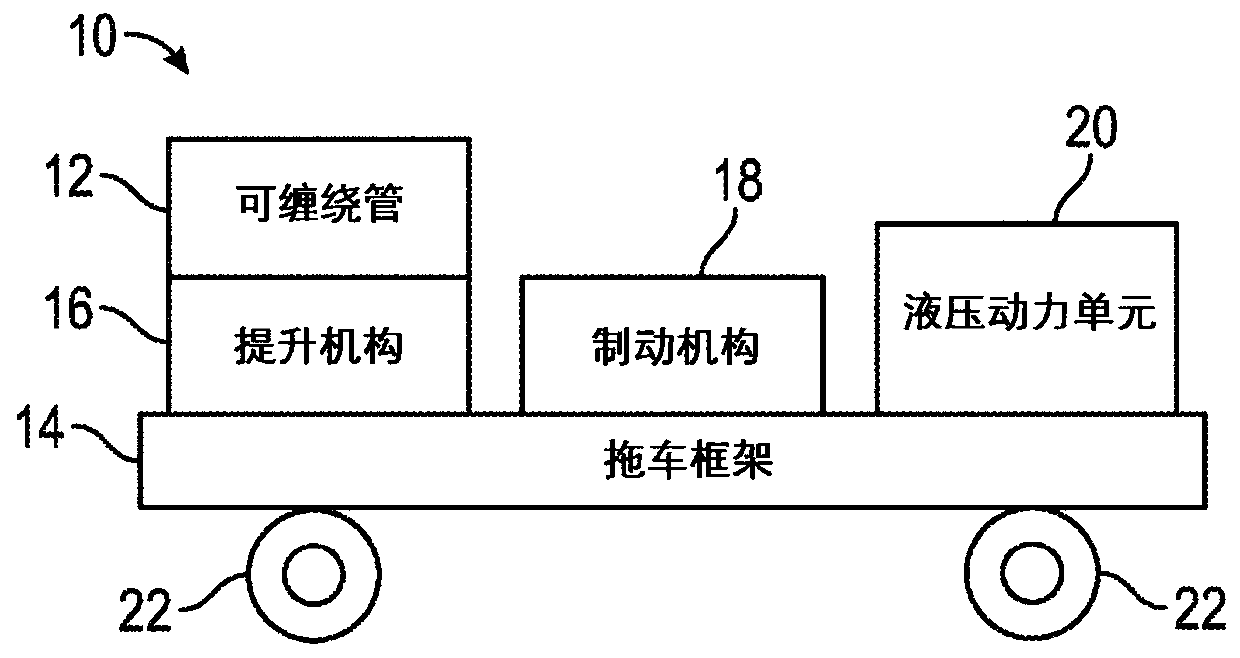

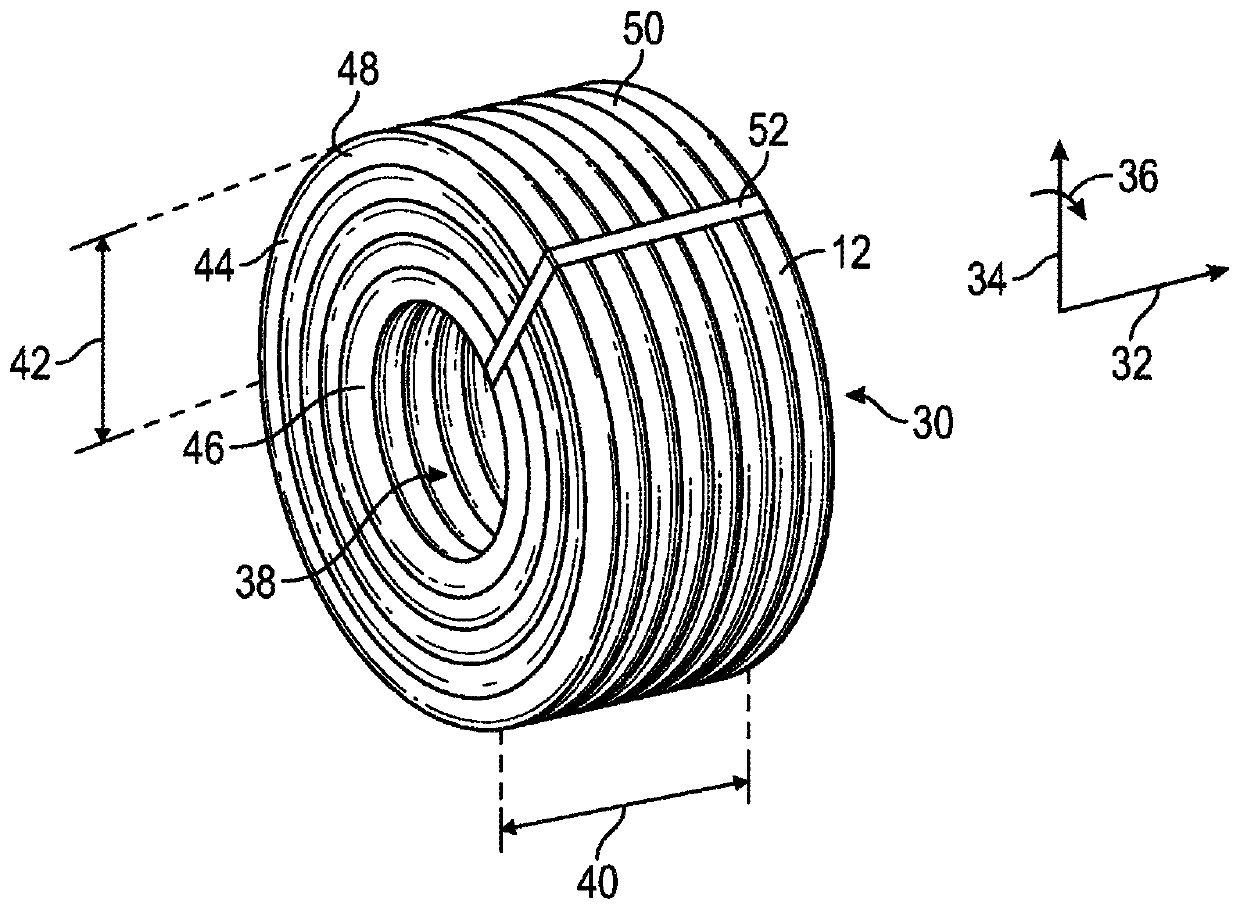

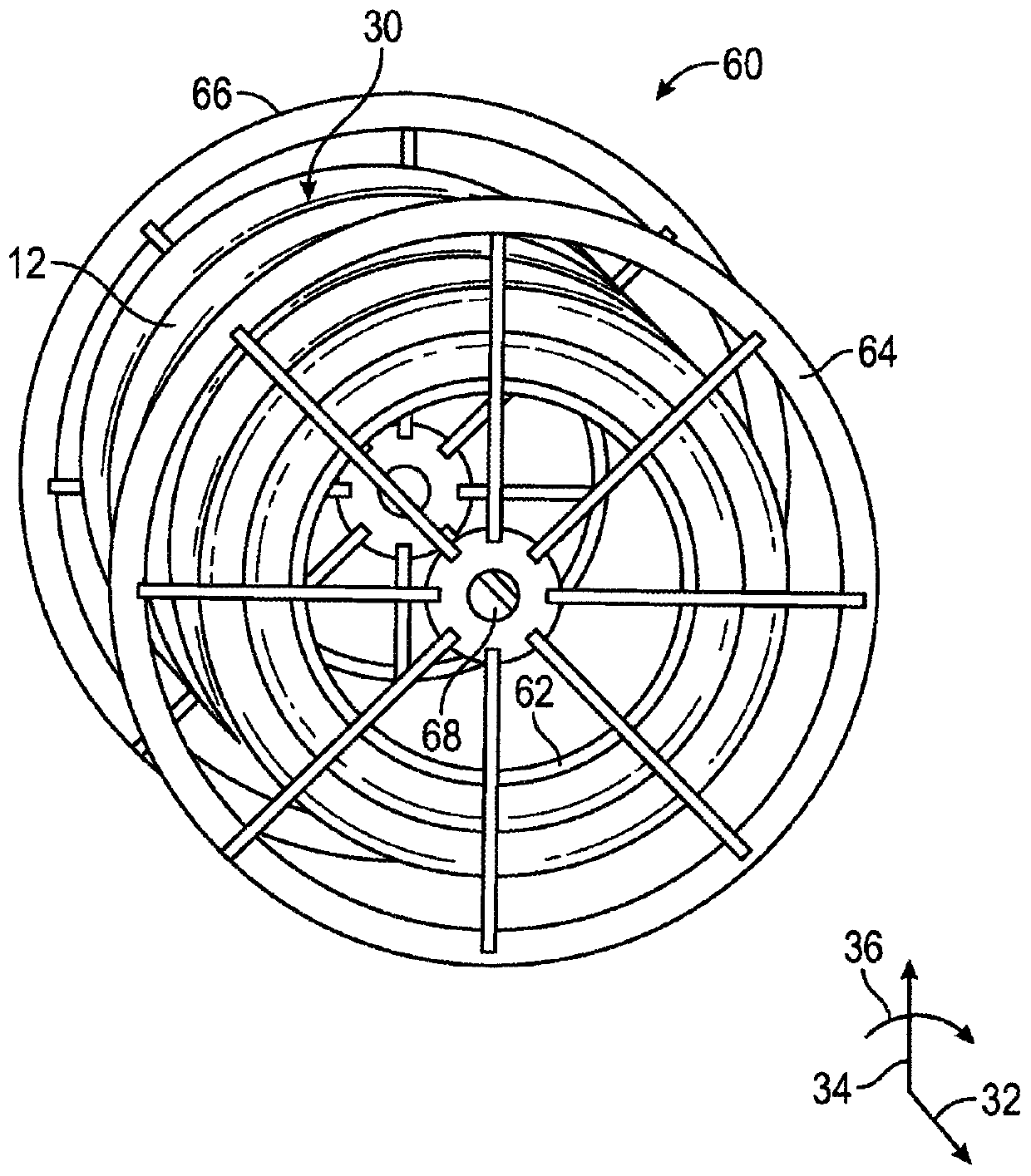

[0035] Embodiments of the present disclosure generally relate to systems for unrolling coils of flexible pipe. The coils of tube may be self-supporting, for example, using straps to hold the coils together. The coil of tube may be self-supporting, for example, using straps to hold the coil together, or the coil of tube may be supported around a roll (which may be referred to as a roll of tube). A deployment system according to embodiments of the present disclosure may include a mounting trailer that includes a trailer frame; a lift mechanism coupled to the trailer frame that is configured to raise or lower a coil of tubing or a spool of tubing; a braking mechanism that a hydraulic power unit configured to hydraulically power the system configured to apply pressure to the tube as it is deployed by the system; and a hydraulic power unit configured to hydraulically power the system.

[0036] Embodiments of the present disclosure will be described below with reference to the draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com