Numerically-controlled bamboo treating device for bamboo product production

A processing device and technology for bamboo products, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of raw material waste, broken bamboo, uneven thickness of bamboo walls, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

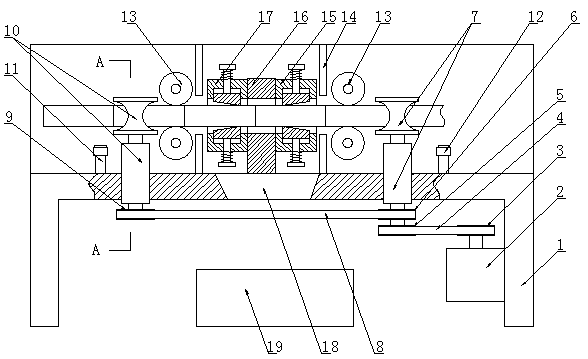

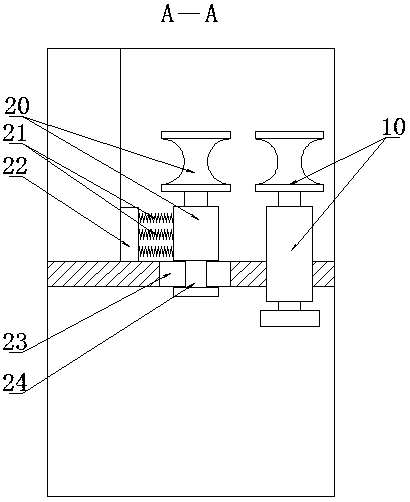

[0016] Embodiment 1, as Figure 1-5 As shown, a numerically controlled bamboo processing device for the production of bamboo products includes a body 1, a motor 2, a driving wheel 3, a first transmission belt 4, a first driven wheel 5, a second driven wheel 6, and a first horizontally fixed feeding wheel 7, the second transmission belt 8, the third driven wheel 9, the second horizontal fixed feeding wheel 10; wherein: the body 1 is equipped with a fixed column 16, and the left and right sides of the fixed column 16 are equipped with a second blue removal mechanism 17, a first blue removal mechanism Mechanism 15, the left side of the second green mechanism 17 and the upper and lower positions on the right side of the first green mechanism 15 are equipped with baffle plate 14, vertical feed wheel 13 is installed on the body 1, vertical feed wheel 13 and body 1 Movably connected, the left and right sides of the body 1 are equipped with a second horizontally fixed feed wheel 10, a...

Embodiment 2

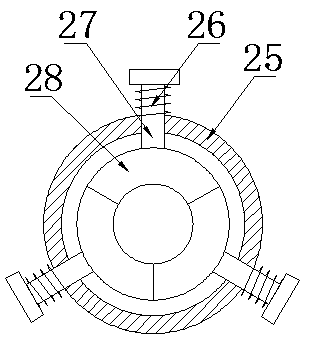

[0017] Embodiment 2, a kind of numerically controlled bamboo treatment device that is used for the production of bamboo products, described the first degreening mechanism 15, the second degreening mechanism 17 are all made of fixed ring 25, second spring 26, T-shaped connecting rod 27, degreening mechanism 17, Green blade 28 is formed; Wherein: be provided with three green blades 28 in described fixed ring 25, each green blade 28 is fixedly connected with T-shaped connecting rod 27, and second spring 26 is worn in T-shaped connecting rod 27, and One end is in contact with the T-shaped link 27 , and the other end is in contact with the fixed ring 25 . The T-shaped link 27 is movably connected with the fixed ring 25 through the second spring 26 . All the other are with embodiment 1.

Embodiment 3

[0018] Embodiment 3. A numerically controlled bamboo processing device for the production of bamboo products, wherein: when the second green removal mechanism 17 is installed on the fixed column 16, it rotates clockwise relative to the first green removal mechanism 15 60 degrees. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com