Green bamboo skin removing machine

A green machine and rack technology, applied in the field of bamboo tube de-greening machine, can solve the problems of high labor intensity, poor bamboo adaptability, low overall efficiency, etc., and achieve the effect of good adaptability and reduced waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

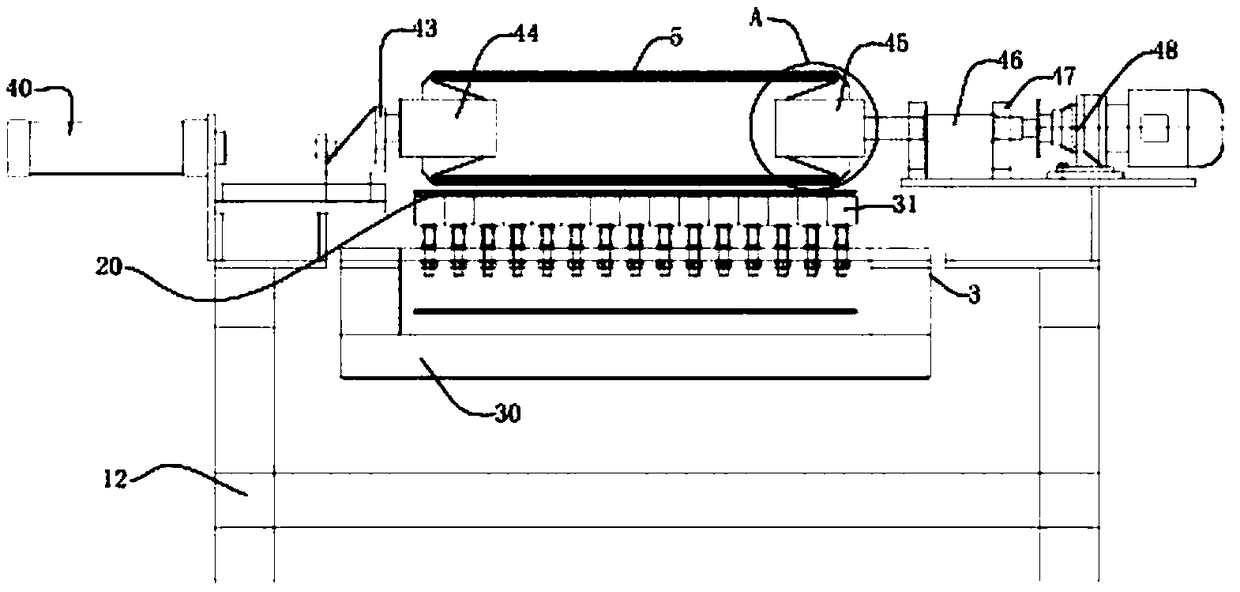

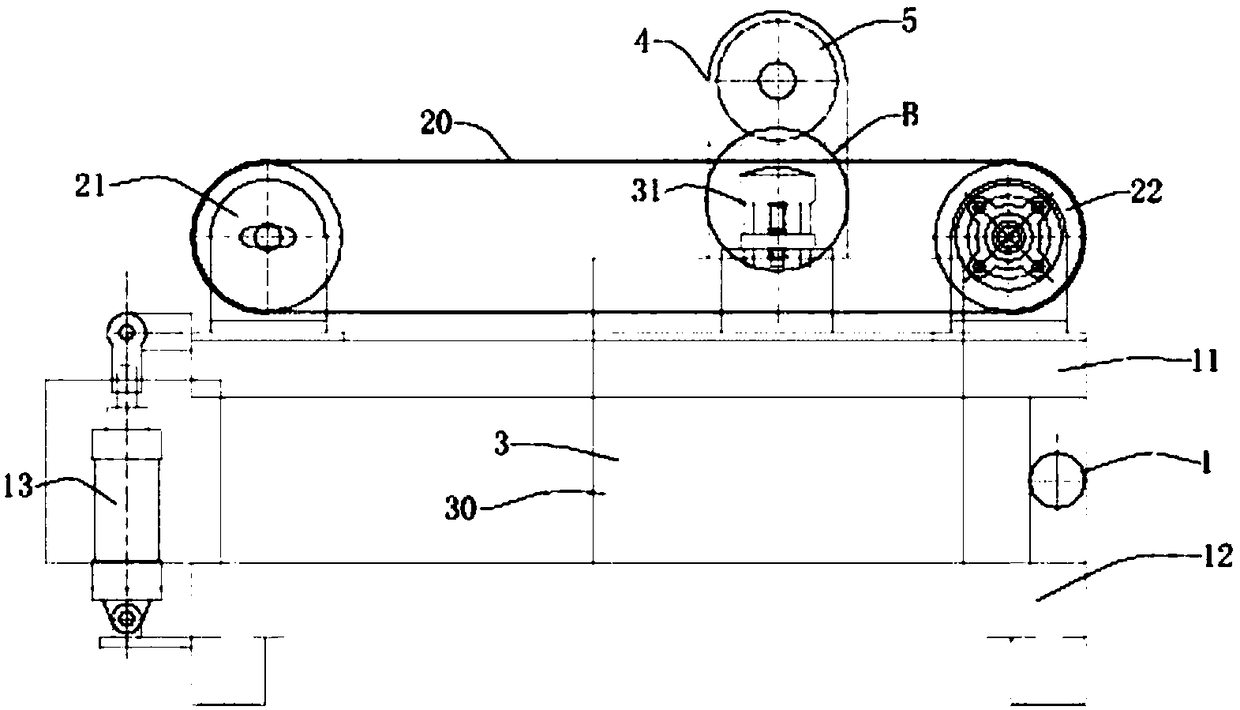

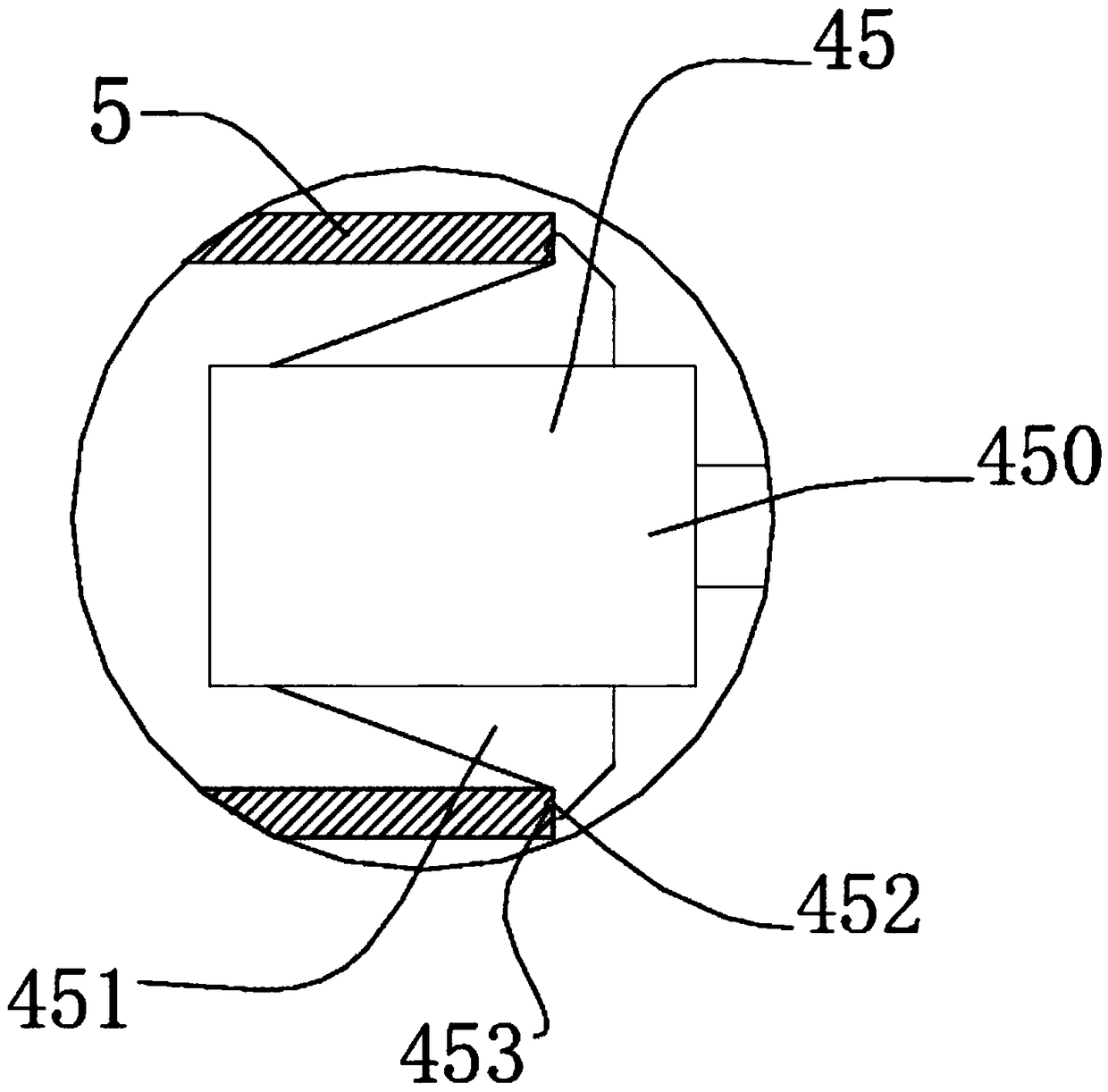

[0025] Example Figure 1-4 Shown a kind of mao bamboon tube goes green machine, and it is the green machine of abrasive belt type, removes the bamboo green on moso bamboo surface by abrasive belt, and it comprises frame 1, the abrasive belt 20 that rolling is installed on the upper frame, The clamping mechanism 4 and the pressing mechanism 3 for installing the bamboo tube 5, wherein the frame 1 is divided into an upper frame 11 and a lower frame 12, and the upper frame 11 and the lower frame 12 are hinged at the same side end in the length direction , The other end of the lower frame 12 and the upper frame 11 in the length direction is connected by a cylinder 13 . When the cylinder 13 is compressed, the main part of the upper frame 11 is kept in a horizontal setting, which is roughly parallel to the main part of the lower frame 12. When the output of the cylinder 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com