Paper cup cover and preparation method thereof

A technology for paper cups and paper lids, applied in the field of cup lids, can solve the problems of large amount of thin paper and adverse effects of beverages, and achieve the effect of saving paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

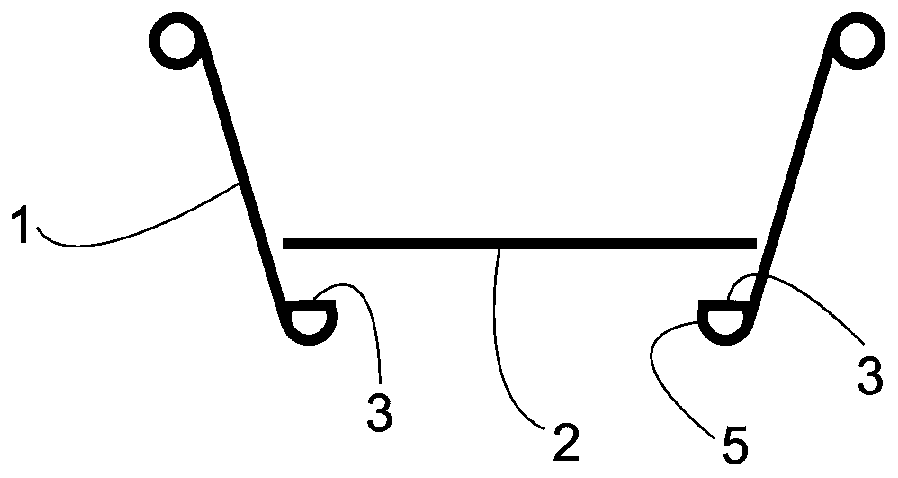

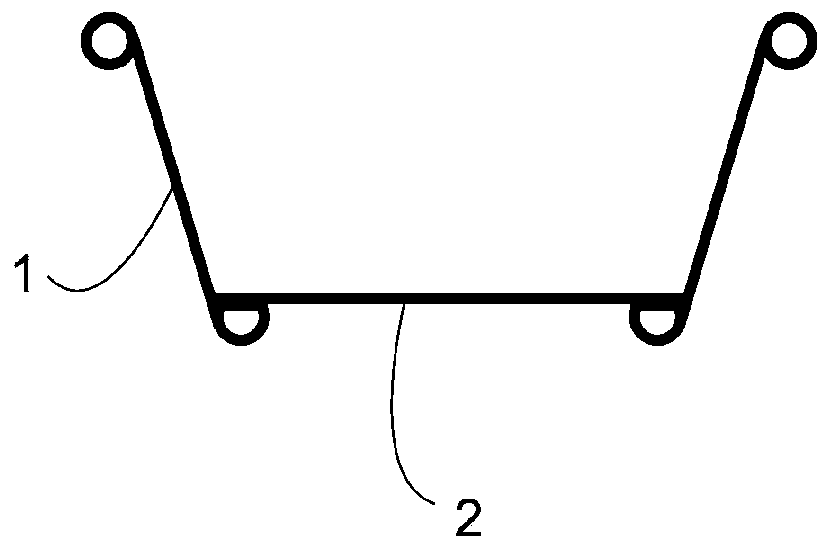

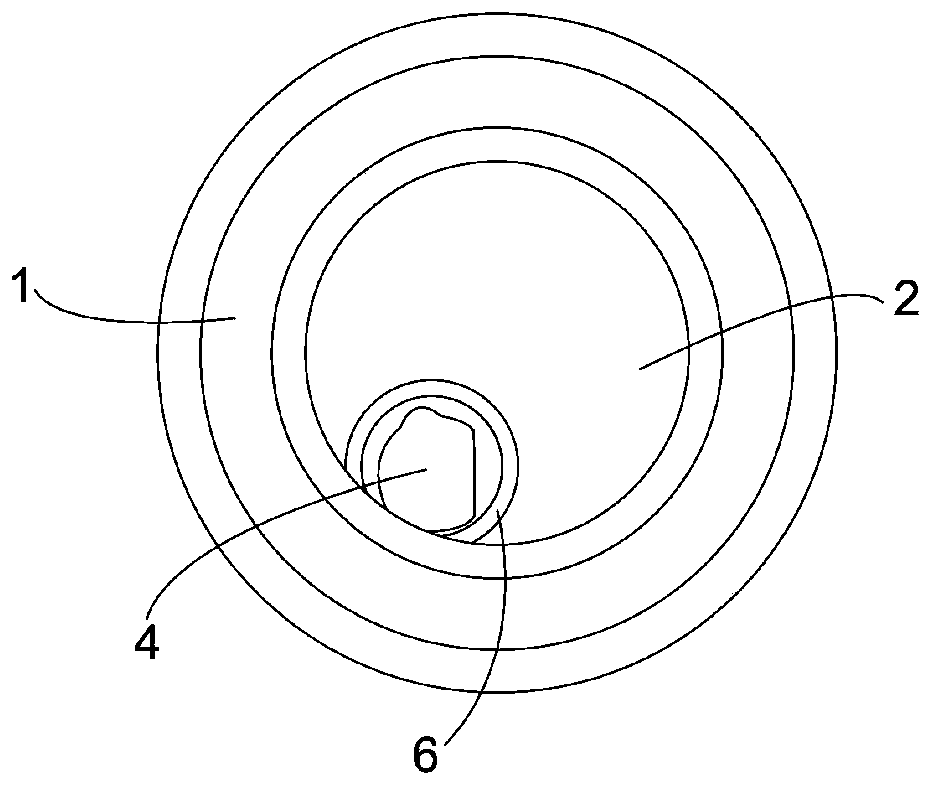

[0028] see Figure 1 to Figure 4 As shown, a paper cup lid includes a hollow paper lid body 1 and a circular paper lid plate 2, the top and bottom ends of the paper lid body 1 are circular, and the paper lid body 2 is generally or roughly in the shape of a truncated cone , the circular edge at the bottom end is rolled up from bottom to top to form an arc-shaped roll, and the upper end of the arc-shaped roll is flattened to form a flat ring-shaped connecting surface 3, which is connected to the paper cover plate 2 Flat edges are press-fitted in place. The rounded edge at the top can also be rolled up in an arc from top to bottom to form another arc roll.

[0029] The paper cover plate 2 of this embodiment may only be a single layer.

[0030] The paper cover 2 of the present embodiment is provided with a drinking port 3, and the shape and size of the drinking port 3 are all matched with a cover 4, and one side of the cover 4 is integrally connected with the paper cover 2; One...

Embodiment 2

[0039] Referring to Embodiment 1, on the basis of Embodiment 1, the arc-shaped roll at the lower end is flattened to form another planar ring-shaped connecting surface 7 . Flattening the upper and lower sides is more convenient for mold processing.

Embodiment 3

[0041] As a preferred embodiment, the circular edge at the top of the paper cover body is rolled up in an arc shape from top to bottom to form another arc roll, thereby forming a high-quality paper cup cover. The other arc-shaped roll can reduce the thickness of the single-layer paper material for curling, and can increase the strength by more than 1 time.

[0042] It should be noted that in the description of the present invention, the orientations indicated by the terms "top", "bottom", "upper", and lower are based on the attached Figure 1-2 The descriptions of the orientations shown are only for the convenience of description, but do not indicate or imply that the components or elements referred to must have specific orientations, and thus should not be construed as limiting the present invention. when attached Figure 1-2 When the position of is rotated by 180°, its corresponding orientation term also changes adaptively, which should not affect the scope of protection of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com