Difunctional freezer support bubble leakage prevention seal part and preparing process thereof

A dual-function, sealing technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of foaming material cost and energy loss, scrapping of the whole machine, etc., and achieve the effect of solving the scrapping of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

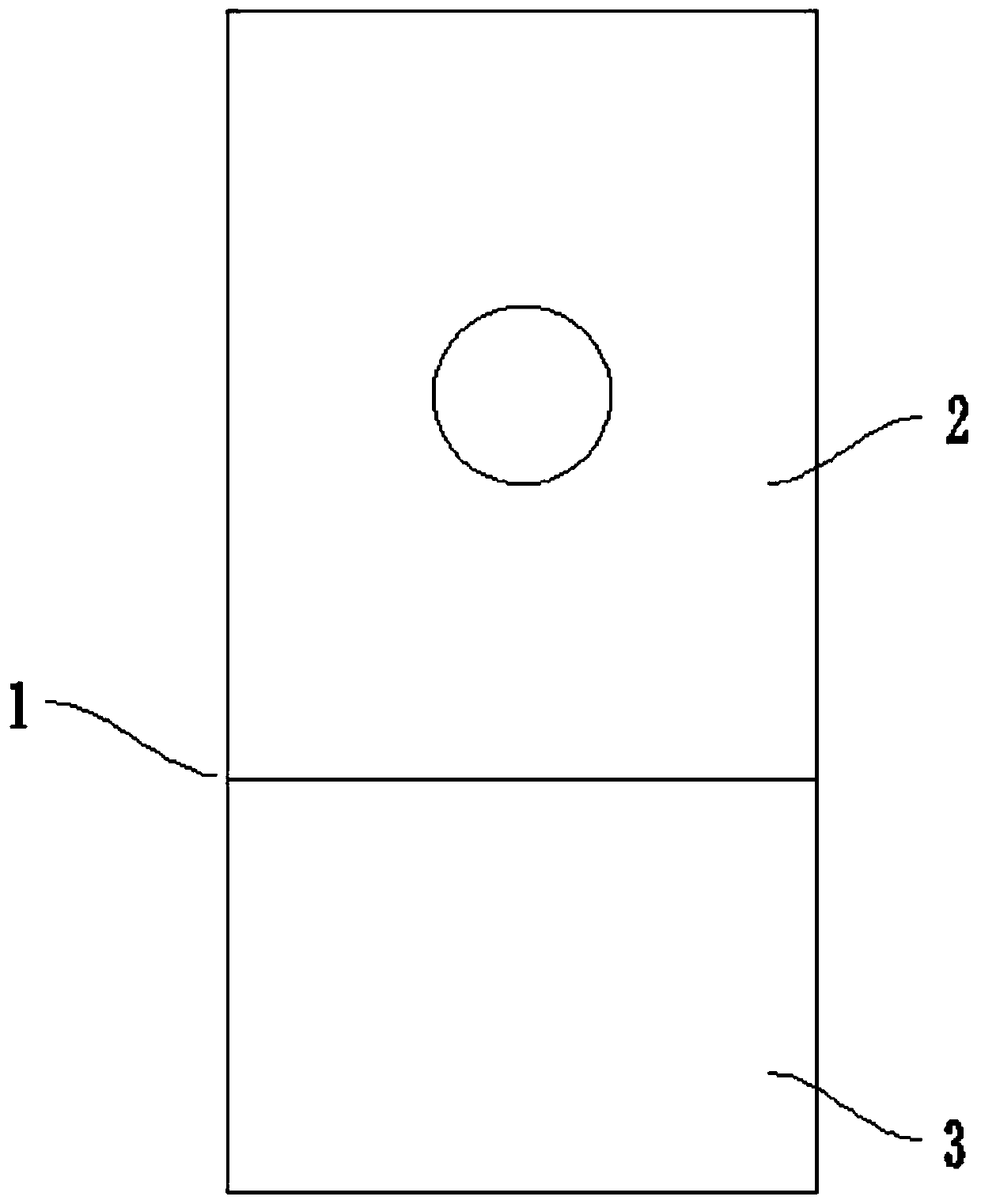

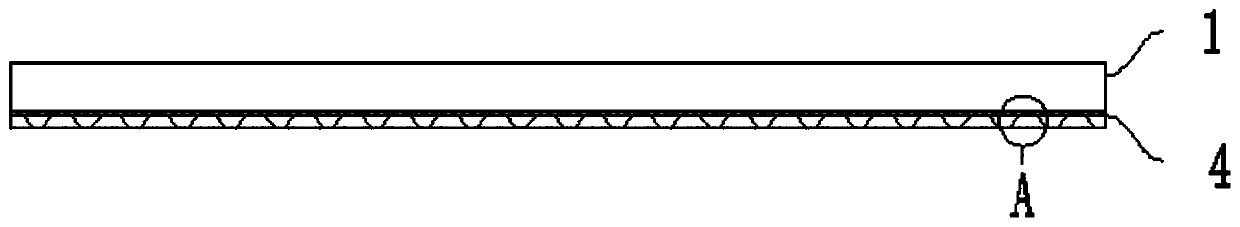

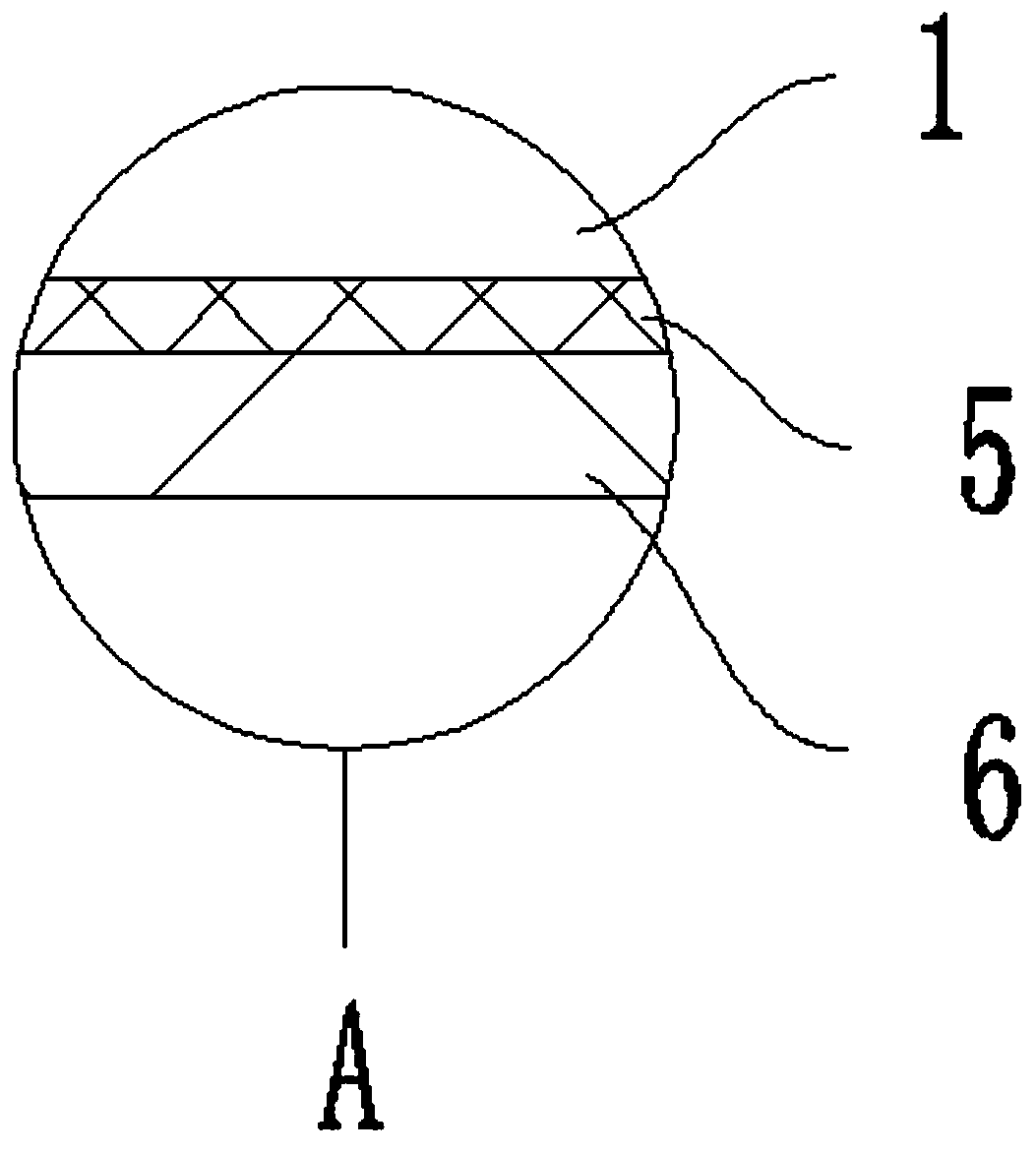

[0030] see Figure 1-3 As shown, the present invention is a double-function freezer support leak-proof bubble seal, including a sealing plate body 1 and a coating layer 2,

[0031] One side of the sealing plate body 1 is provided with a coating layer 2;

[0032] Wherein, the sealing plate body 1 is divided into an opening part 2 and a sealing part 3, and the opening part 2 has a through hole matched with the installed condensing pipe or water pipe;

[0033] Wherein, coating layer 2 glue layer 5 and release paper 6, glue layer 5 is attached on the side of sealing plate body 1, and release paper 6 is attached on the outside of glue layer 5.

[0034] Further, the through hole formed on the hole portion 2 is located at the center of the area.

[0035] Further, the thickness of the sealing plate body 1 is 4-12mm.

[0036] Further, the sealing plate body 1 adopts one or more of PU, PE, EPDM or rubber-plastic viscose sponge.

[0037] Further, the material density of the sealing p...

Embodiment 2

[0041] The main material of sealing plate body 1 includes the following parts by weight: highly reactive polyether polyol: 75 parts, TDI: 36 parts, DEOA: 1.2 parts, water: 3.5 parts, L5333: 0.75 parts, A230: 0.16 parts, D22: 0.018 parts .

Embodiment 3

[0043] The main material of sealing plate body 1 includes the following parts by weight: highly reactive polyether polyol: 85 parts, TDI: 50 parts, DEOA: 2.2 parts, water: 4.0 parts, L5333: 1.0 parts, A230: 0.22 parts, D22: 0.026 parts share.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com