Combined defoaming and siphoning well and combined defoaming and siphoning method

A siphon well, combined technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve problems such as aggravating foam, visual pollution, and affecting the environment of the sea area of the power station, achieving uniform water flow and solving the effect of air bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

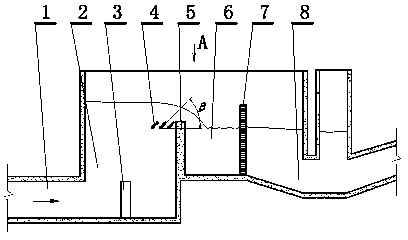

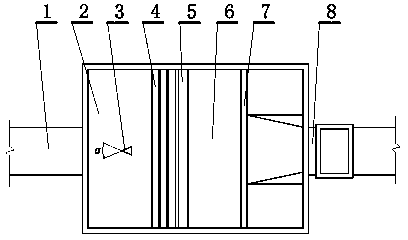

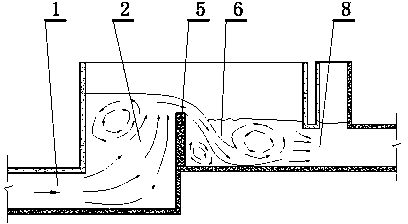

[0026] This embodiment is a combined defoaming siphon well, such as figure 1 , 2 shown. This embodiment includes at least one siphon well assembly, the siphon well assembly includes a vertical shaft 2 with a water inlet culvert 1, the vertical shaft is connected to the overflow pool 6, the connection between the overflow pool and the vertical shaft An overflow weir 5 is arranged between them, and the overflow weir is arranged on the side opposite to the water inlet side culvert in the shaft, and the water delivery side culvert 8 is arranged on the side opposite to the overflow weir in the overflow pool. , between the water inlet square culvert at the bottom of the vertical shaft and the overflow weir, a diversion pier 3 is arranged on the central axis facing the water inlet side culvert in the water outlet direction, and the overflow weir is on one side of the vertical shaft, close to the overflow weir The position of the top is provided with a horizontally arranged weir fro...

Embodiment 2

[0039] This embodiment is an improvement of the first embodiment, and it is a refinement of the siphon well combination in the first embodiment. This embodiment includes two siphon well combinations arranged side by side, and the siphon well combination shares a side wall. The central axis of the outlet direction of the water delivery culvert is offset to the common side wall, such as Figure 5 shown.

[0040] In this embodiment, a power station uses two siphon well combinations arranged side by side. When the drainage changes greatly in winter and summer, and the external water level changes also relatively large, two or three siphon well combinations can be used to adapt to these changes. . However, if there are too many siphon well combinations, the engineering cost will increase exponentially, which must be considered. Now a power station basically uses one combination, so that when half of the units are overhauled, a siphon well combination will not affect the power gen...

Embodiment 3

[0042] This embodiment is an improvement of the above-mentioned embodiment, and is a refinement of the above-mentioned embodiment regarding the diversion pier. The horizontal cross-sectional shape of the diversion pier in this embodiment is an isosceles triangle, the apex of the isosceles triangle is the water-facing surface, and the bottom is the backwater surface, and the height of the diversion pier is from the bottom of the siphon well to the outlet of the water inlet square culvert. level at the top, such as figure 1 , 2 shown.

[0043] The function of the triangular diversion pier is to divert the water body at the outlet of the water inlet square culvert to both sides, so as to prevent the water body from concentrating in the middle of the shaft and flowing out, resulting in excessive fluctuation of the water body.

[0044] The triangle is an isosceles triangle, and its vertex angle can be selected within a certain range. If the angle is too large, it will act like a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com