Composite drainage pipeline

A drainage pipe and drainage channel technology, applied in the direction of pipe components, etc., can solve the problems of drainage pipe burst, economic loss, water source loss, etc., and achieve the effect of increasing water delivery, saving precious time, and reducing water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

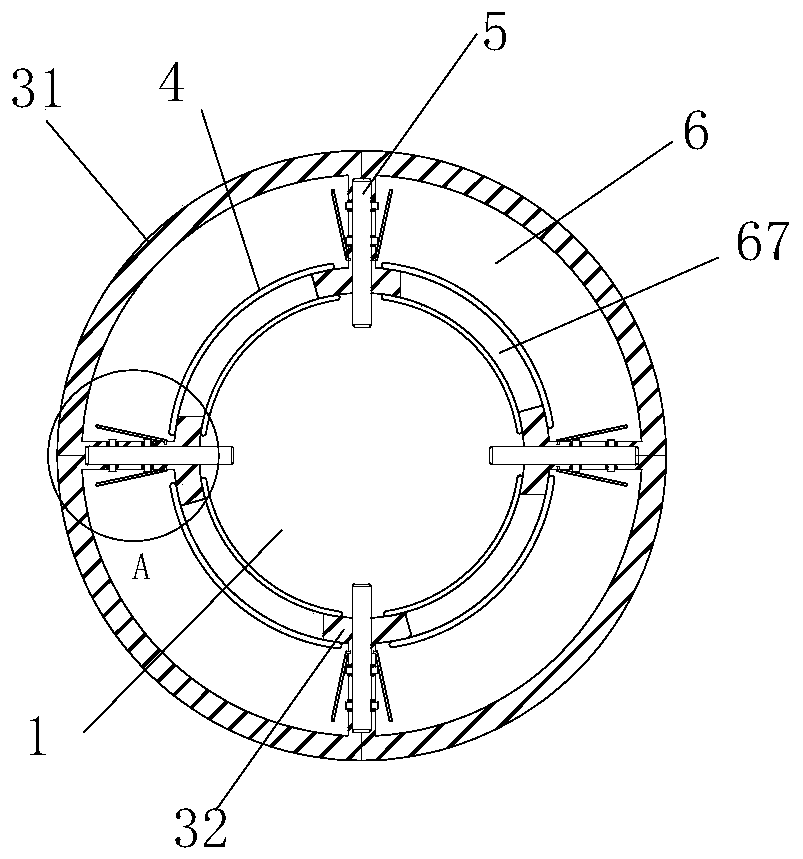

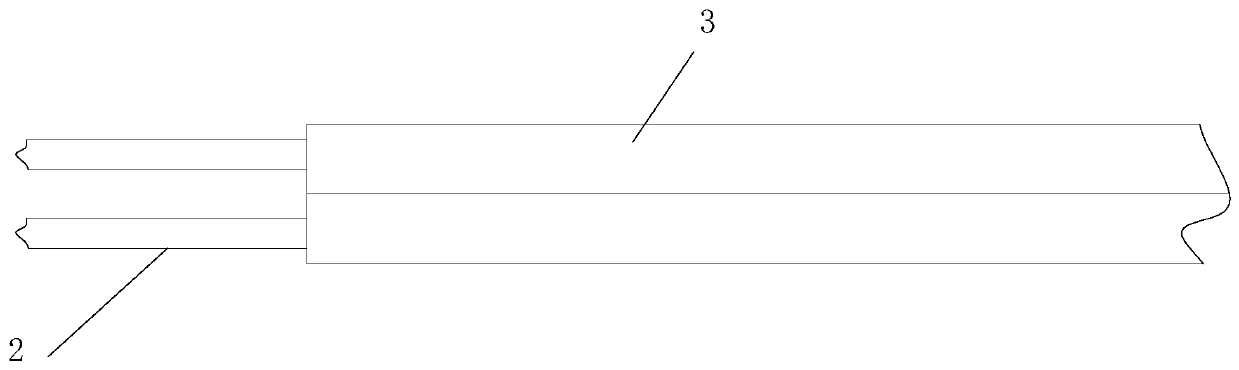

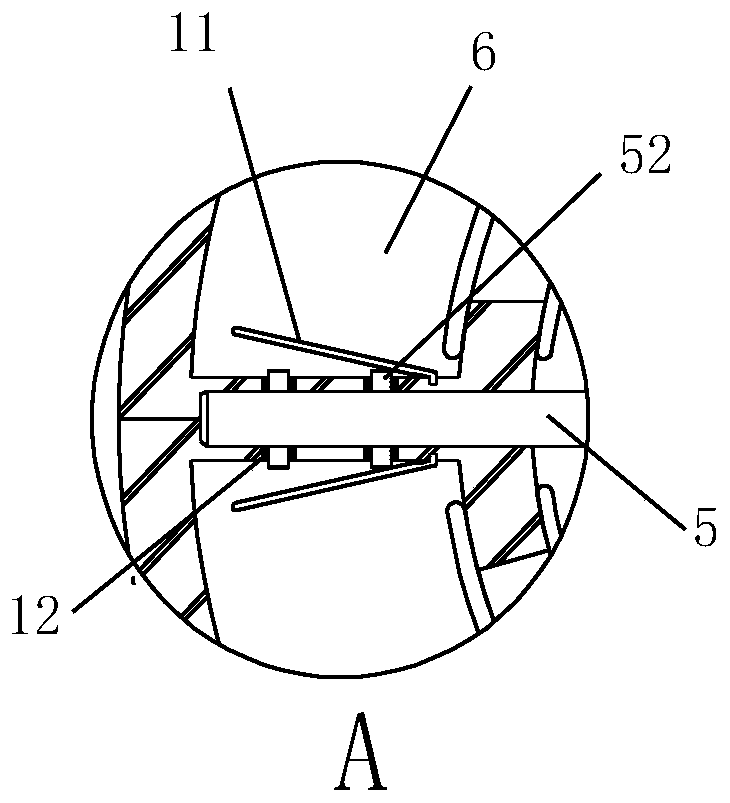

[0017] Such as figure 1 and figure 2 As shown, the composite drainage pipe includes a cylindrical drainage pipe spliced by four arc-shaped shell parts 3, a circular main drainage channel 1 is formed in the middle, and a closed closed pipe is formed in the middle of each arc-shaped shell part 3. And the independent auxiliary drainage channel 6, the splicing surface of the arc-shaped shell part 3 is respectively equidistantly provided with more than one semicircular groove, and the semicircular grooves on two adjacent splicing surfaces form a circular positioning hole A water guide assembly 5 is installed between two adjacent semicircular grooves, and the water guide assembly 5 guides the water in the auxiliary drainage channel into the main drainage channel for discharge. The inner wall of the drainage channel 6 is provided with a seal facing the water guide assembly, and the water guide assembly 5 pushes away from the seal. The water source input end of each arc-shaped sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com