Printheads for applying coatings to components

A technology of coating agent and printing head, which is applied in the direction of surface coating liquid devices, coatings, spraying devices, etc., which can solve problems such as difficult flushing of the printing head, coating deposition, failure, etc., and improve leakage safety , fast color change, short rinsing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

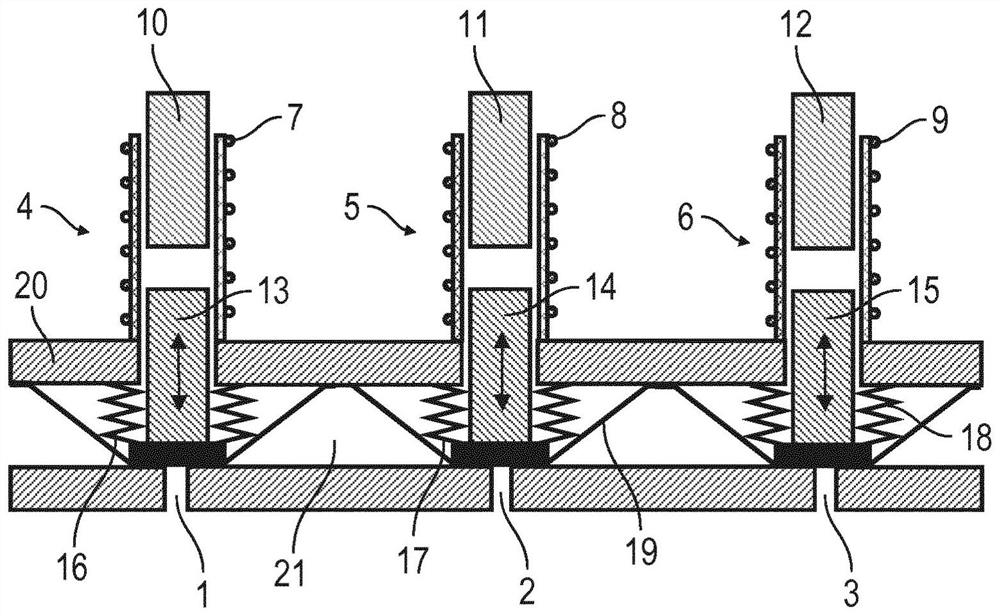

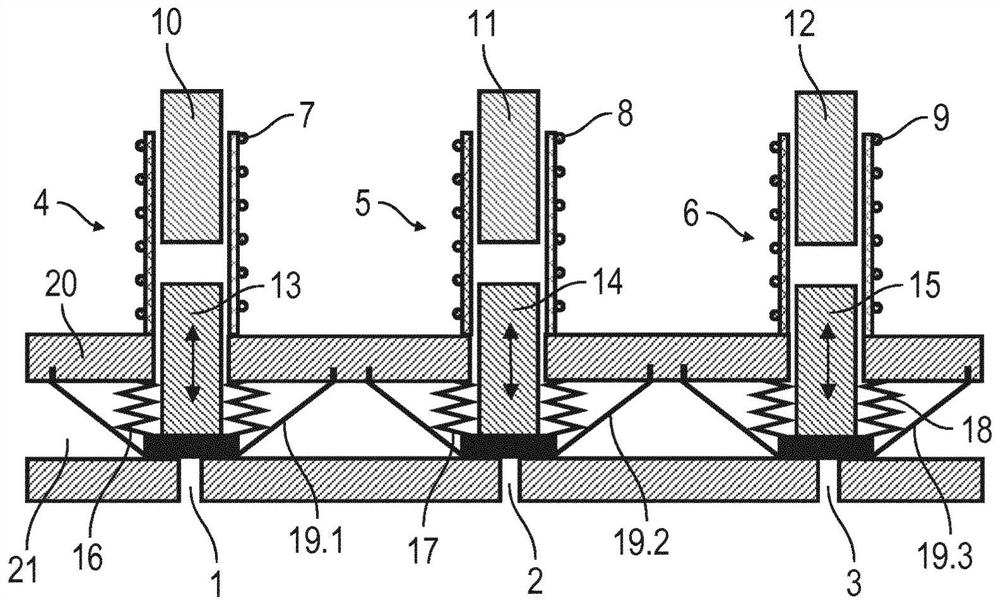

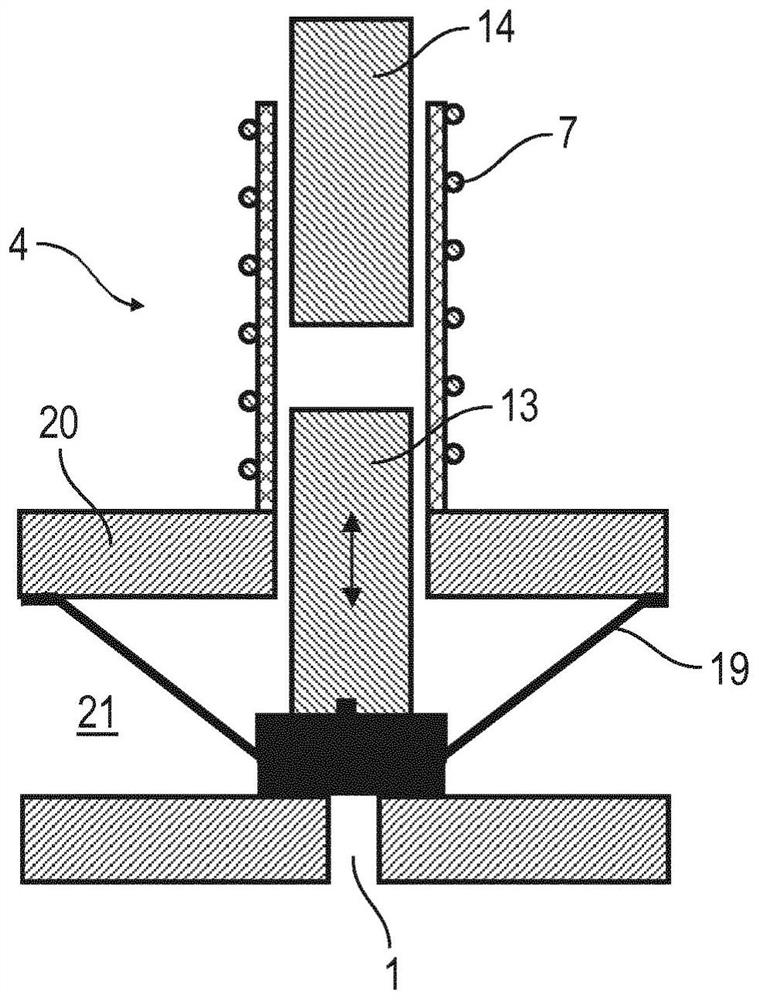

[0055] figure 1 Shows a schematic diagram of a print head according to the invention, which can be used, for example, for the application of paint in the continuous painting of body parts in a paint shop, wherein the print head is controlled by a robot with standard robot kinematics. Multi-axis painting robot guidance.

[0056] The print head has a plurality of nozzles 1, 2, 3 in the nozzle plate in order to apply paint to the part surface of the part to be painted, whereby spatially narrow paint jets (continuous or in the form of droplets). To simplify matters, only three nozzles 1-3 are shown in the figure. In reality, however, the printhead has a greater number of nozzles.

[0057] Each of the nozzles 1-3 is correspondingly equipped with a control valve 4, 5 or 6 to open or close the nozzle 1-3.

[0058] The individual control valves 4 - 6 each have a coil 7 , 8 or 9 with a coil core 10 , 11 or 12 .

[0059] Furthermore, the control valves 4 - 6 each have a movable arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com