Method and device for monitoring corrosion state of stainless steel in aqueous medium

A corrosion state and monitoring device technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as high system stability requirements, natural potential fluctuation errors, etc., to achieve clear criteria and reduce disturbances effect, the effect of low polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

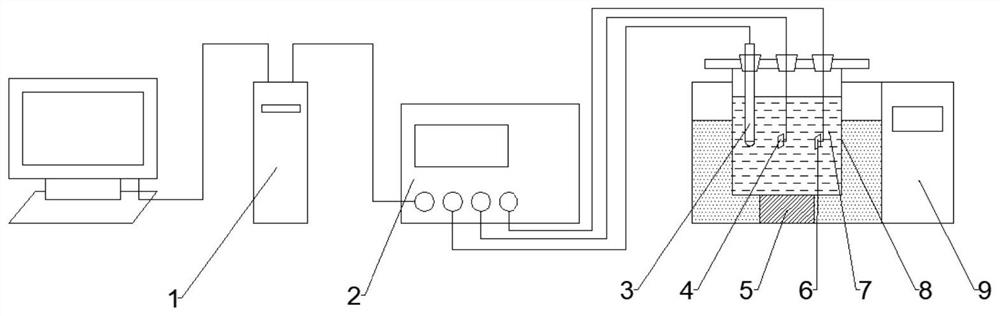

[0039] like image 3 As shown in the figure, the stainless steel corrosion state monitoring device in the water medium of this embodiment includes: a computer 1, which can detect the natural potential E of the working electrode in the three-electrode system 0 and polarization resistance R p 2, a three-electrode system (a system composed of a working electrode 4, a counter electrode 6 and a reference electrode 3), and a test container 8 containing an aqueous medium 7. The test container 8 and the spacer 5 are set in the water bath 9 , and the test container 8 is set on the spacer 5 . The auxiliary device, the water bath 9 and the spacer 5, is optional according to actual needs. The electrochemical detection instrument 2 is connected to the computer 1 . The computer 1 may also be built in the electrochemical detection instrument 2 .

[0040] The materials of the working electrode and the counter electrode of the three-electrode system are made of the same stainless steel as ...

Embodiment 2

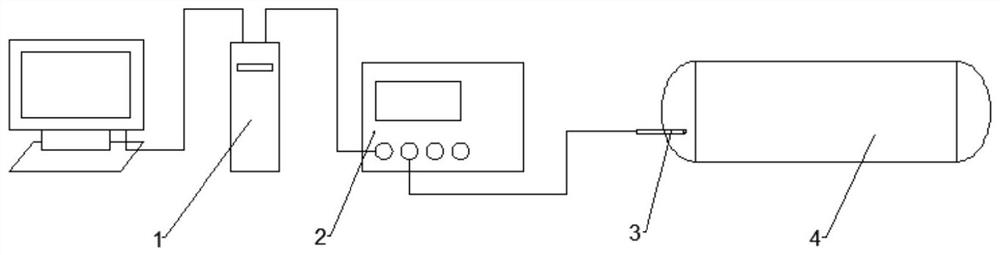

[0052] like figure 1 As shown, the stainless steel corrosion state monitoring device in the water medium of this embodiment is mainly used for monitoring equipment in non-laboratory. The stainless steel corrosion state monitoring device in the water medium includes: a computer 1, a monitoring probe 3 including a three-electrode system, which can detect the natural potential E of the working electrode in the three-electrode system 0 and polarization resistance R p 2; stainless steel equipment 4 (such as stainless steel heat exchangers, condensers, containers, etc.). The electrochemical detection instrument 2 is connected to the computer 1 . The computer 1 may also be built in the electrochemical detection instrument 2 . The three-electrode system is a system composed of a working electrode, a counter electrode and a reference electrode. The monitoring probe 3 is a combination of the working electrode, the counter electrode and the reference electrode. The head of the monitor...

Embodiment 3

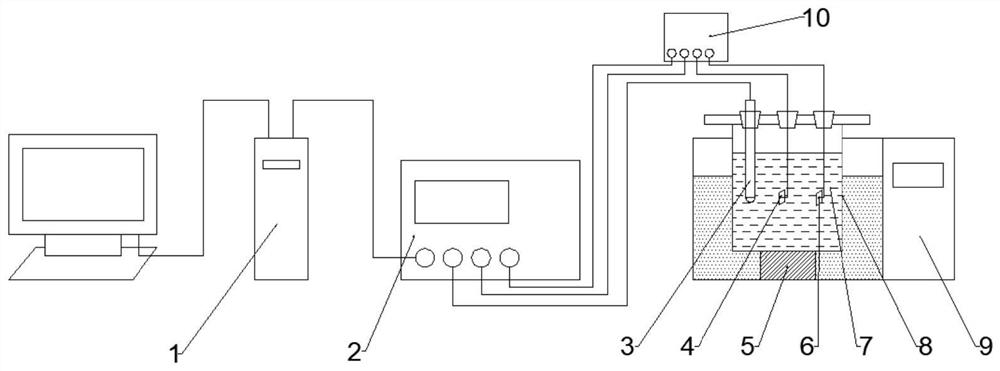

[0055] like figure 2 As shown in the figure, the stainless steel corrosion state monitoring device in the water medium of this embodiment includes: a computer 1, which can detect the natural potential E of the working electrode in the three-electrode system 0 and polarization resistance R p The electrochemical detection instrument 2, a three-electrode system (a system composed of a working electrode 4, a counter electrode 6 and a reference electrode 3), a test container (beaker) 8 containing an aqueous medium 7 and an intermediate converter 10 . The electrochemical detection instrument 2 is connected to the computer 1 . The computer 1 may also be built in the electrochemical detection instrument 2 . The test container 8 and the spacer block 5 are set in the water bath 9 , and the test container 8 is set on the spacer block 5 . The auxiliary device, the water bath 9 and the spacer 5, is optional according to actual needs. The materials of the working electrode 4 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com