Force-transmitting structure and its construction method of post-cast belt on foundation pit floor

A construction method and post-casting belt technology, which can be used in infrastructure engineering, excavation, construction, etc., and can solve problems such as foundation pit collapse and ineffective transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

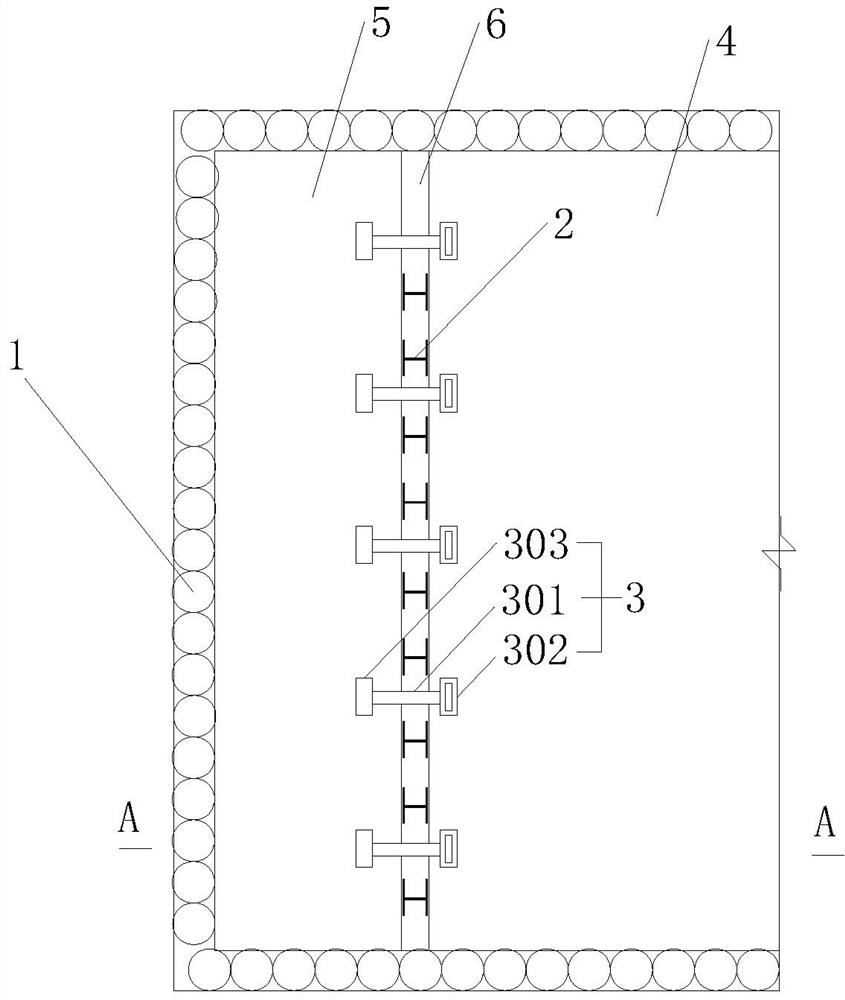

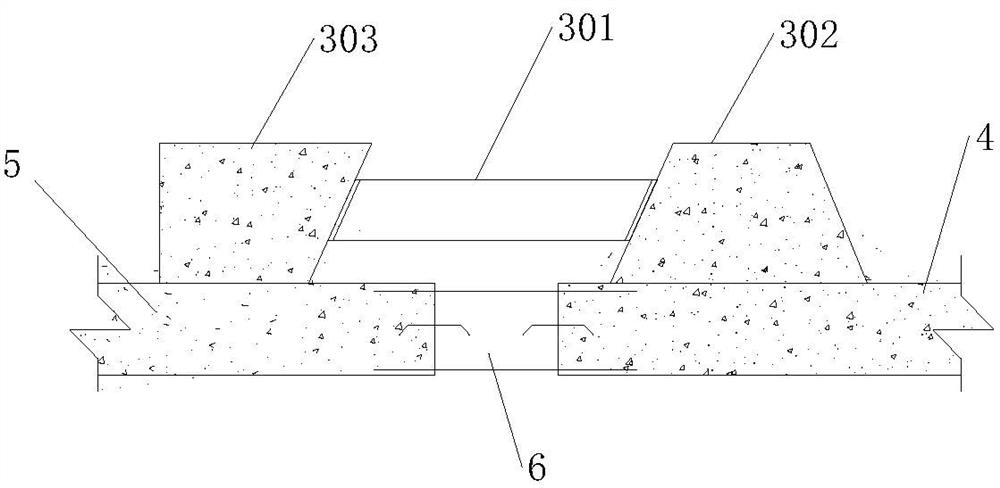

[0034] A post-casting belt force transmission structure for foundation pit floor, such as figure 1 and figure 2 shown, including:

[0035] A plurality of first steel members 2 arranged along the extension direction of the back-casting belt 6 are sandwiched between the bottom plates on both sides of the back-casting belt 6, and between the first bottom plate 4 and the second bottom plate 5. The two ends of the member 2 are respectively fully fitted with the end faces of the first base plate 4 and the second base plate 5 to ensure uniform force transmission; the height of the first steel member 2 should be less than the height of the post-casting belt 6, and the reserved steel bars shall prevail. The first steel member 2 can be made of I-beam, H-shaped steel or assembled and welded with steel plates; Calculation OK.

[0036] The plurality of corbel force transmission units 3 arranged along the extension direction of the back casting belt 6 include: a first corbel 302 fixed o...

Embodiment 2

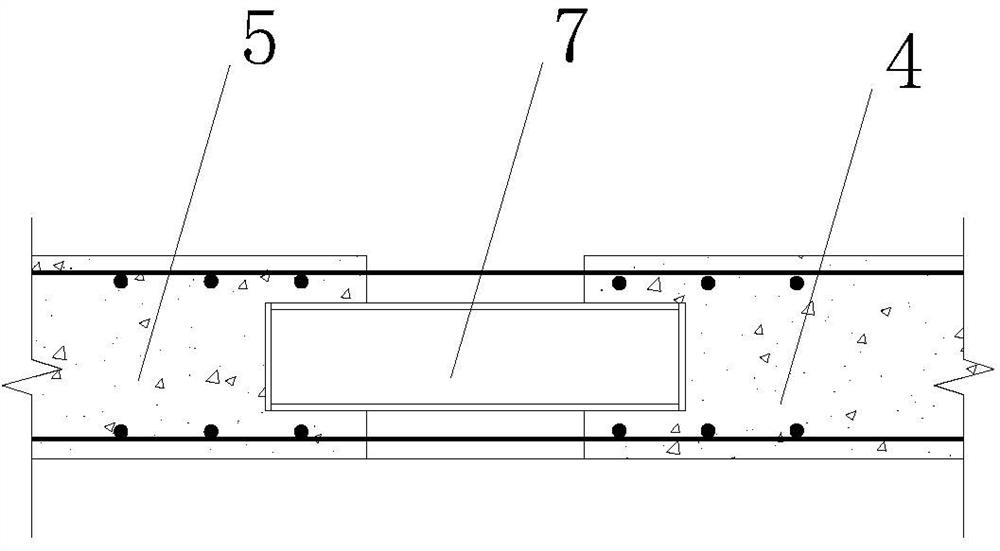

[0050] Embodiment 2 is a further improvement of Embodiment 1 to further enhance the stability of the horizontal force transmission structure of the bottom plate. On the basis of Example 1, as image 3 As shown, a plurality of second steel members 7 are distributed along the extension direction of the post-casting belt 6 , and both ends of the second steel members 7 are buried in the concrete of the bottom plates on both sides of the post-casting belt 6 . The second steel member 7 can be I-shaped steel, H-shaped steel or assembled and welded with steel plates.

Embodiment 3

[0052] Embodiment 3 is a further improvement of Embodiment 1 to further enhance the stability of the horizontal force transmission structure of the bottom plate. On the basis of Example 1, as Figure 4 As shown, at the post-casting belt 6 position, at least one reinforcing bar 9 is welded and fixed on the main reinforcement 8 of the bottom plate on both sides of the post-casting belt 6 , and the reinforcing steel bar is arranged in the same direction as the main rib 8 .

[0053] Further, a reinforcement bar 9 is fixed on both sides of the main bar 8, and the diameter of the reinforcement bar 9 is the same as that of the main bar 8, and its length is more than 1 m. Preferably, a reinforcement bar 9 with a length of 2 m is selected.

[0054] In an optional implementation of this embodiment, a plurality of second steel members 7 are also distributed along the extension direction of the post-cast belt 6, and the two ends of the second steel members 7 are embedded in the concrete o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com