A Calibration Method of Yarn Tension Based on Load Cell

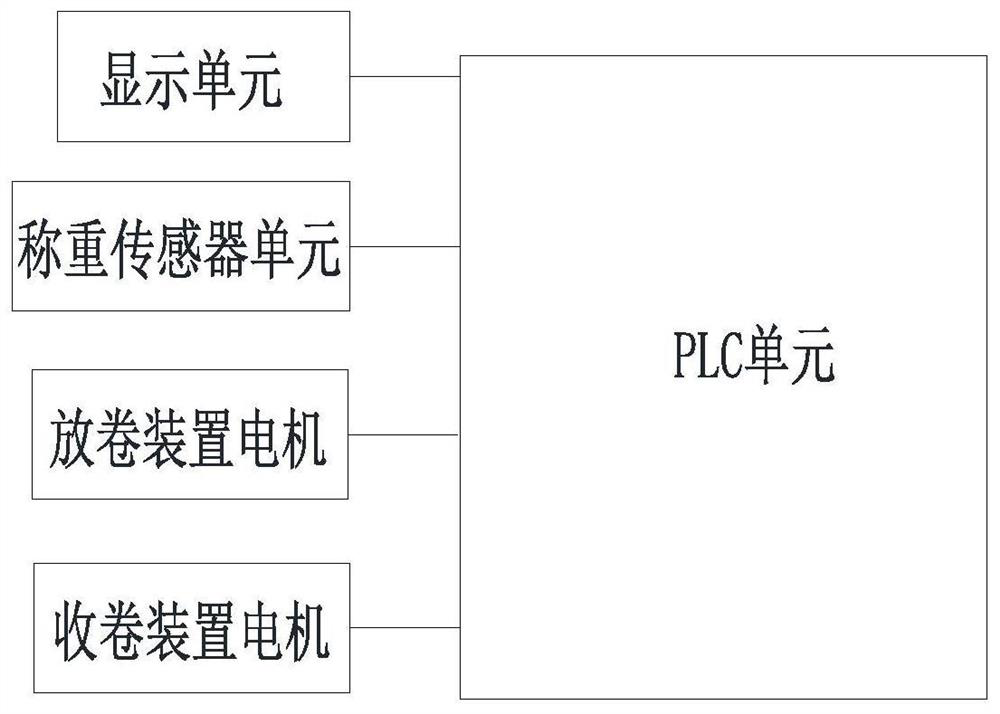

A weighing sensor and yarn tension technology, applied in tension measurement, instruments, force/torque/work measuring instruments, etc., can solve the problem that the appearance and mechanical properties cannot meet the requirements, the yarn tension cannot be displayed in real time, and the yarn width can be changed And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

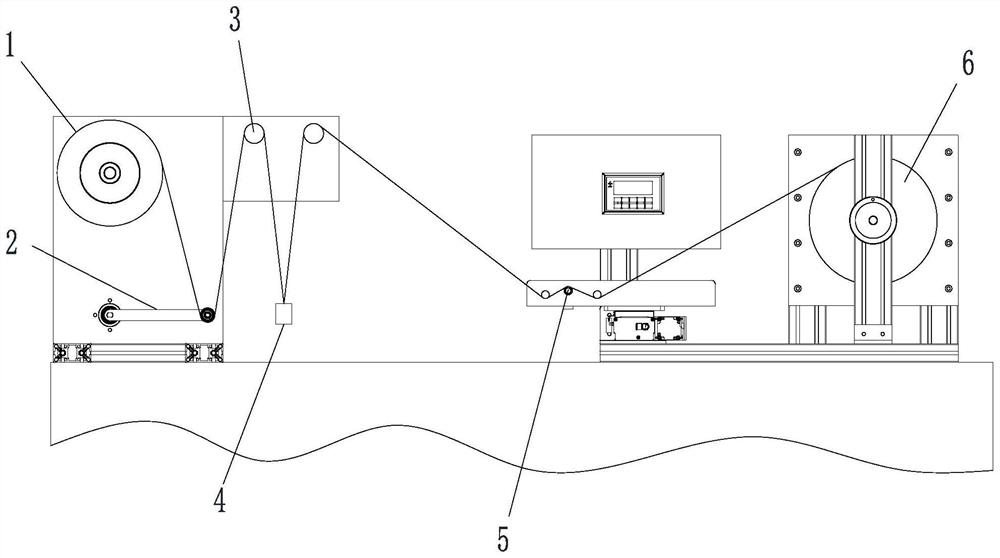

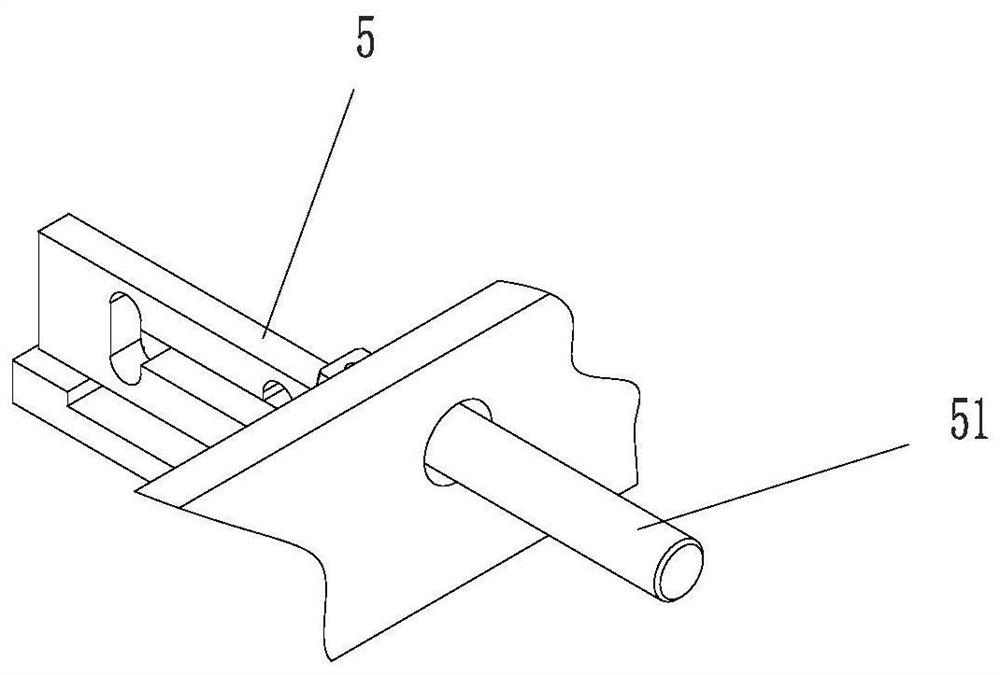

[0044] Such as figure 1 and 2 Shown, the present invention relates to a kind of carbon glass fiber spreading device, comprising:

[0045] The unwinding device 1, the yarn is stored in the unwinding device 1, and the yarn is released by the rotation of the unwinding device 1;

[0046] Yarn pendulum 2, one end is rotatably connected to the bracket where unwinding device 1 is located, and the other end is provided with a guide roller for yarn wrapping around. When the tension on the yarn increases, the yarn pendulum 2 swings, Thus keeping the yarn tension constant;

[0047] Two yarn storage rods 3 are arranged in parallel, and a weight 4 is hung on the yarn passing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com