On-line detection system for tension of steel wire rope for elevator

A detection system and elevator system technology, applied in the field of detection systems, can solve the problems of unbalanced tension of wire ropes, expensive precision, and low levels, and achieve the effects of easy maintenance, increased safety factor, and high data reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

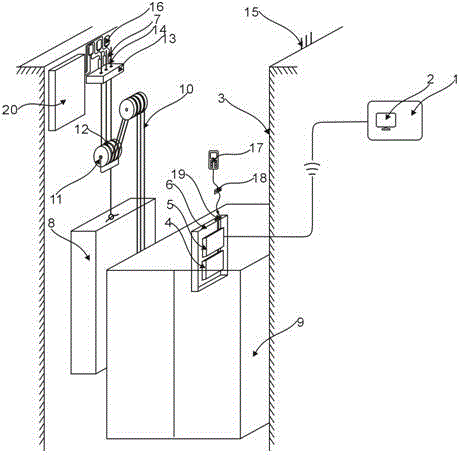

[0026] like figure 1 As shown, the present invention relates to an elevator wire rope tensioning force online detection system, including a cloud server 1, a sensor 7, a handheld monitor 17, an intelligent decision-making terminal 4 and an elevator system; the elevator system in the detection system and the traditional elevator system The same, including the hoistway 3, the intelligent decision-making terminal 4, the counterweight 8, the car 9, the traction wire rope 10, the movable pulley 11, the rope groove 12, and the wire rope head fixing plate 13. The improvement lies in:

[0027] Sensors 7 are respectively installed on the rope heads A14 and B15 of the rope heads on both sides of the traction wire rope 10 for sensing the tension of the two rope heads;

[0028] The sensor 7 is provided with an information collection board 16, which collects the tension force data induced on the sensor 7 and displays it on the display screen of the sensor 7 in real time; the sensor is conn...

Embodiment 2

[0036] like figure 1 As shown in the figure, an on-line detection system for elevator wire rope tensioning force involved in the present invention includes a cloud server 1, a sensor 7, a handheld monitor 17, an intelligent decision terminal 4 and an elevator system; its basic structure is the same as that of the first embodiment, but different The point is that the sensor 7 is separately arranged at the wire rope head A14 to detect the tension data at the wire rope head A14.

Embodiment 3

[0038] like figure 1As shown in the figure, an on-line detection system for elevator wire rope tensioning force involved in the present invention includes a cloud server 1, a sensor 7, a handheld monitor 17, an intelligent decision terminal 4 and an elevator system; its basic structure is the same as that of the first embodiment, but different The point is that the sensor 7 is separately arranged at the wire rope head B15 to detect the tension data at the wire rope head B15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com