Cable stripping device for power construction

A technology for electric power construction and cables, which is applied in the field of cable stripping devices, and can solve problems such as hand pain, wasted effort, and heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

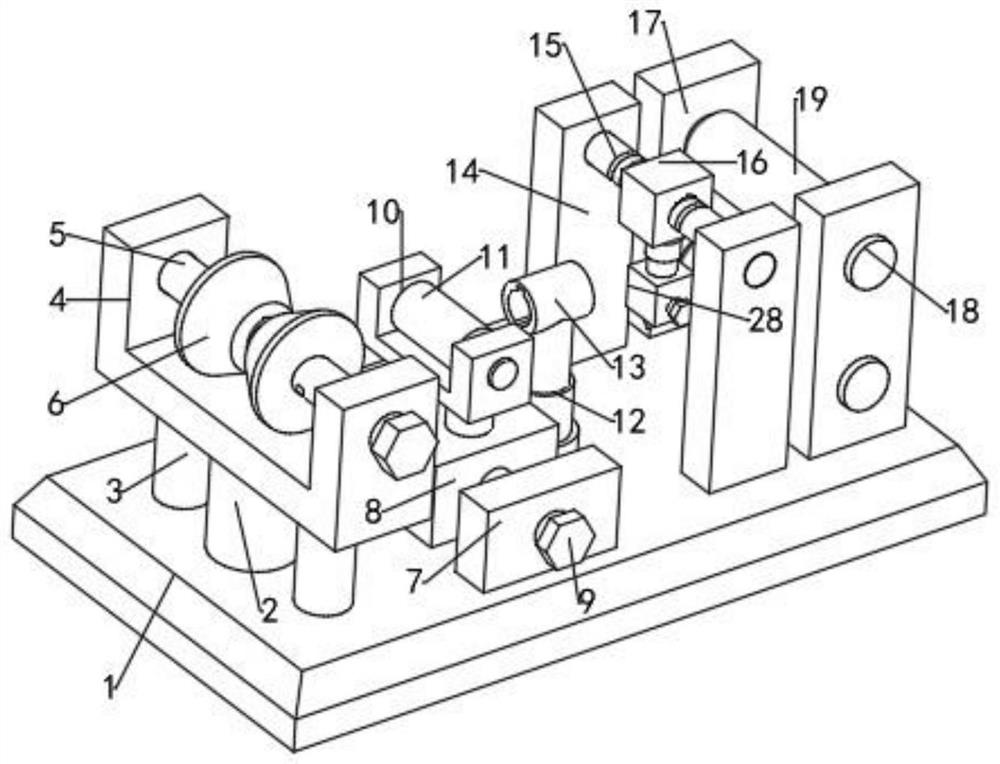

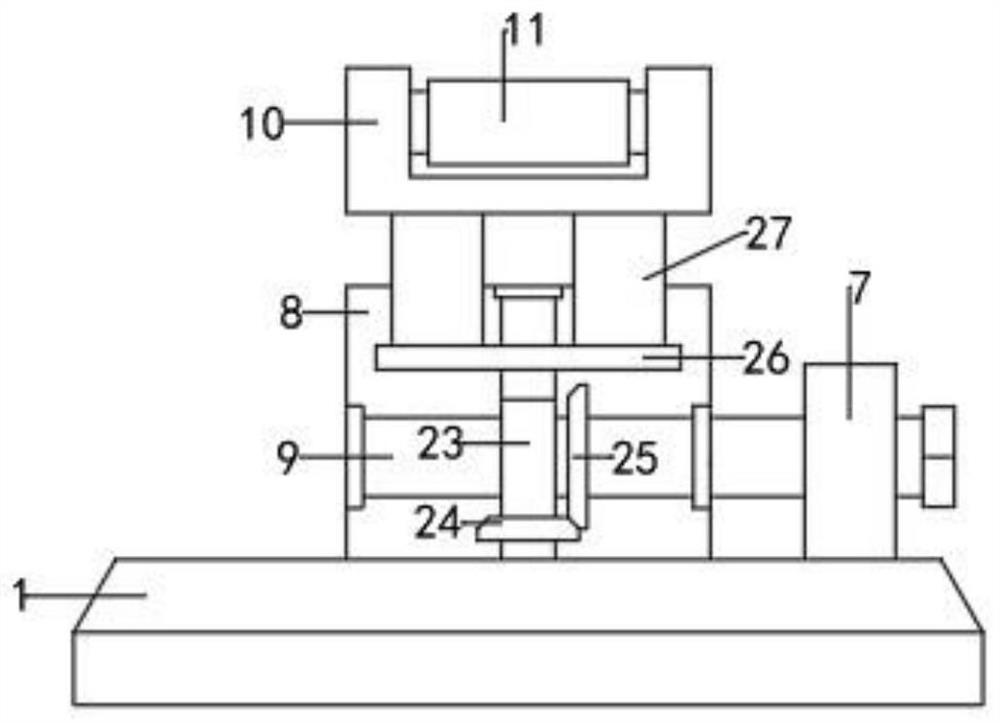

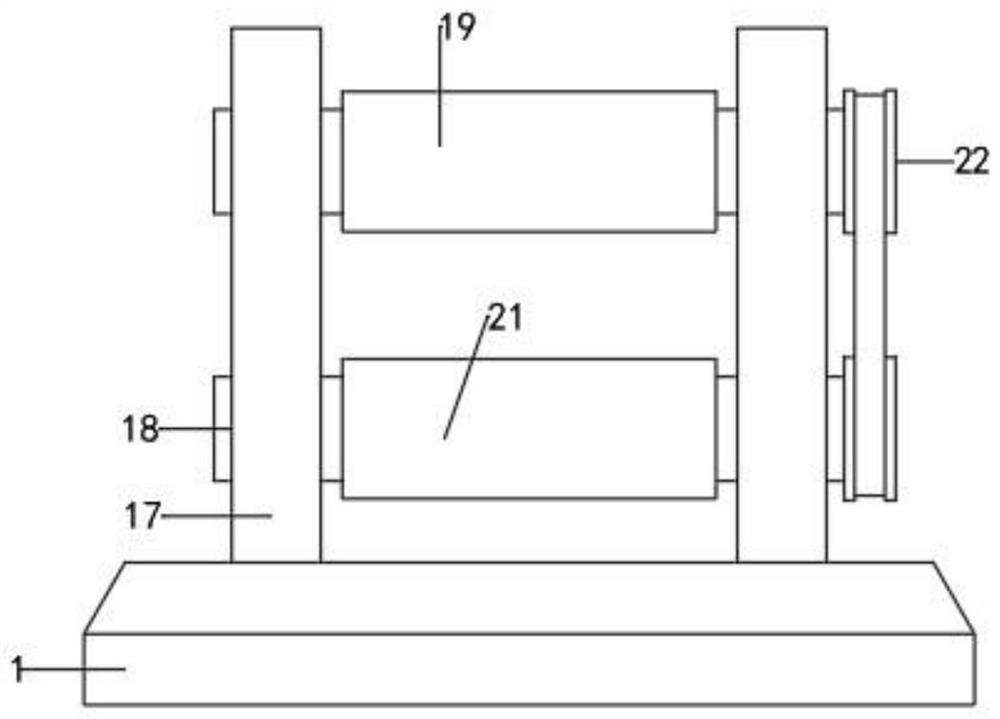

[0022] see Figure 1-6 , a cable stripping device for electric power construction, comprising a base 1, a mounting seat 4 is arranged on one side of the upper end surface of the base 1, a clamping mechanism is arranged on the mounting seat 4, and one side of the clamping mechanism is arranged in sequence There is a cutting mechanism and a winding mechanism; the clamping mechanism includes a clamping disc 6, a vertical frame 2 is fixedly connected between the lower end of the mounting seat 4 and the base 1, and vertical frames are arranged on both sides of the frame 2. The supporting rod 3 is used to enhance the connection strength between the mounting base 4 and the base 1; the cross section of the mounting base 4 is concave, and the mounting base 4 is equipped with a horizontal adjusting screw 5, and one end of the adjusting screw 5 extends to the installation The outer side of the seat 4; the adjusting screw 5 is equipped with two oppositely arranged clamping discs 6, the cl...

Embodiment 2

[0031] In order to facilitate the installation and fixation of the cable stripping device for electric power construction in actual use, this embodiment is improved on the basis of embodiment 1. The improvement is: the four corners of the base 1 are provided with through threads holes, so that in actual use, the cable stripping device for electric power construction is clamped and fixed with bolts, which is convenient for operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com