Tension-adjustable two-roller active scutching device

An open-width device and active technology, applied in transportation and packaging, winding strips, thin material processing, etc., can solve the problems of unsatisfactory opening-width ideal effect, increase equipment investment, difficult adjustment, etc., and achieve open-width wrinkle removal Good effect, easy tension adjustment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below with reference to the drawings.

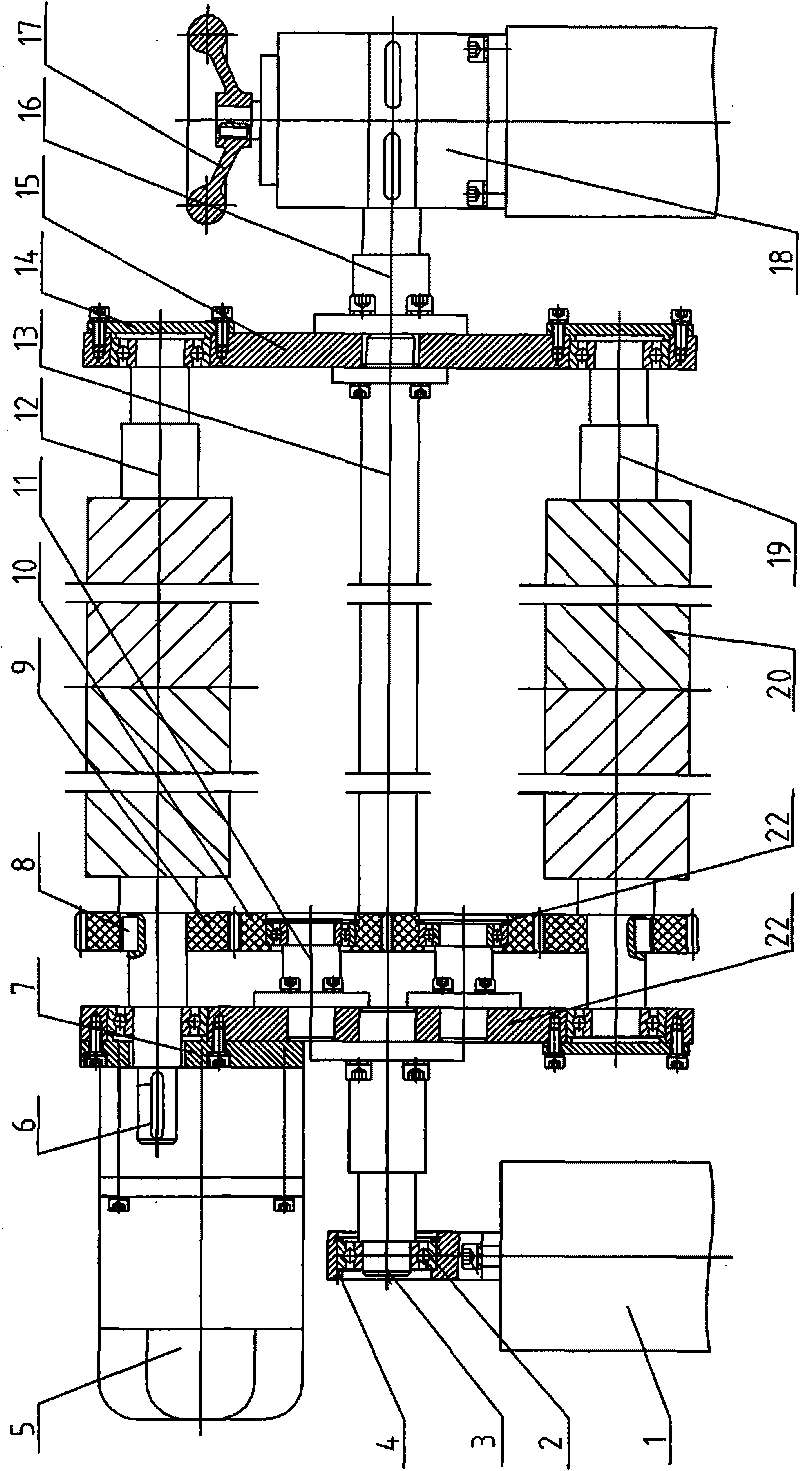

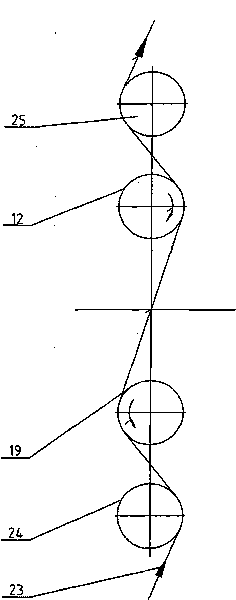

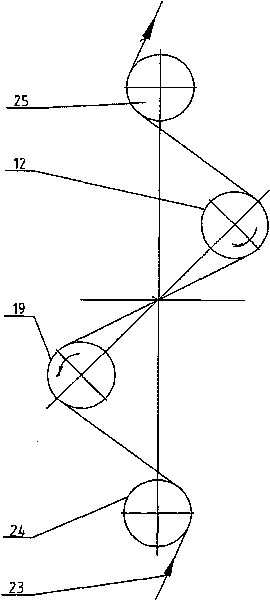

[0016] The double-roller active opening device with adjustable tension of the present invention includes an integral frame, a transmission mechanism, an upper opening roller 12 and a lower opening roller 19.

[0017] The integral frame includes a left supporting shaft 3, a connecting brace 13, a right side plate 15, a right supporting shaft 16, and a left side plate 22. The middle parts of the symmetrically arranged left side plate 22 and right side plate 15 are connected to form a rigid whole through the connecting brace 13; on the outside of the left side plate 22 and the right side plate 15 corresponding to the connecting brace 13 are respectively installed the left support shaft 3 and the right The supporting shaft 16 makes the axes of the left supporting shaft 3, the right supporting shaft 16 and the connecting support 13 on the same horizontal line. The outer shaft end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com