Visualized big container experimental method of boiling heat transfer

A technology of boiling heat transfer and experimental methods, applied in instruments, scientific instruments, thermal analysis of materials, etc., can solve the problems of no air bubbles, difficulty in observing jet flow, and inability to effectively control the temperature difference in the heating process, so as to achieve easy adjustment, Easy to adjust the experiment and observe the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

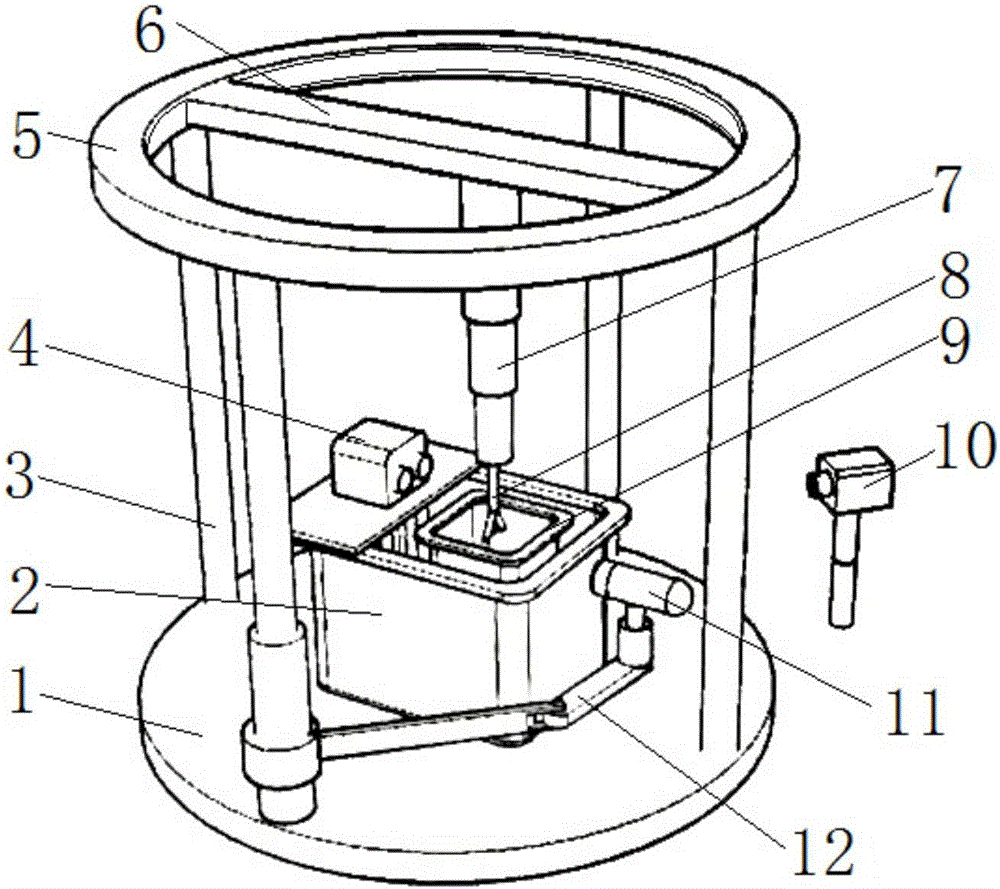

[0047] Combine figure 1 , The experimental device for a visualized large container of this embodiment is mainly composed of a bracket, a heating wire fixing and adjusting mechanism, a water bath heating mechanism, a high-speed camera 10 and a scanning electron microscope 11, etc. The heating wire fixing and adjusting mechanism includes a heating wire adjusting mechanism and a heating wire The fixing mechanism, the heating wire adjusting mechanism is connected with the bracket, and is used for horizontally or vertically adjusting the heating wire fixing adjusting mechanism. The water bath heating mechanism is located below the heating wire fixing and adjusting mechanism, and the boiling heating wire 17 on the heating wire fixing mechanism is heated in the water bath heating mechanism.

[0048] The support in this embodiment is mainly composed of an experimental platform base 1 and an experimental platform pillar 3. The three experimental platform pillars 3 are evenly spaced in the ...

Embodiment 2

[0056] The basic structure of a visualized large container experimental device of this embodiment is the same as that of embodiment 1, and the difference is that: the heating wire adjustment mechanism in this embodiment is mainly composed of the top ring 5 of the test bench, the lifting support rod fixing frame 6 and Composed of lifting struts 7. Among them, the top ring 5 of the test bench is fixed on the top of the column 3 of the test bench, and is horizontally fixed. The inner wall of the top ring 5 of the test bench is provided with an annular groove. The two ends of the support rod fixing frame 6 are located in the annular groove, the lifting support rod fixing frame 6 can rotate around the central axis of the top ring 5 of the test bench, and the lifting support rod fixing frame 6 can also be arranged radially above the top ring 5 of the test bench. The main purpose is to achieve rotation, and the specific structure is not particularly limited.

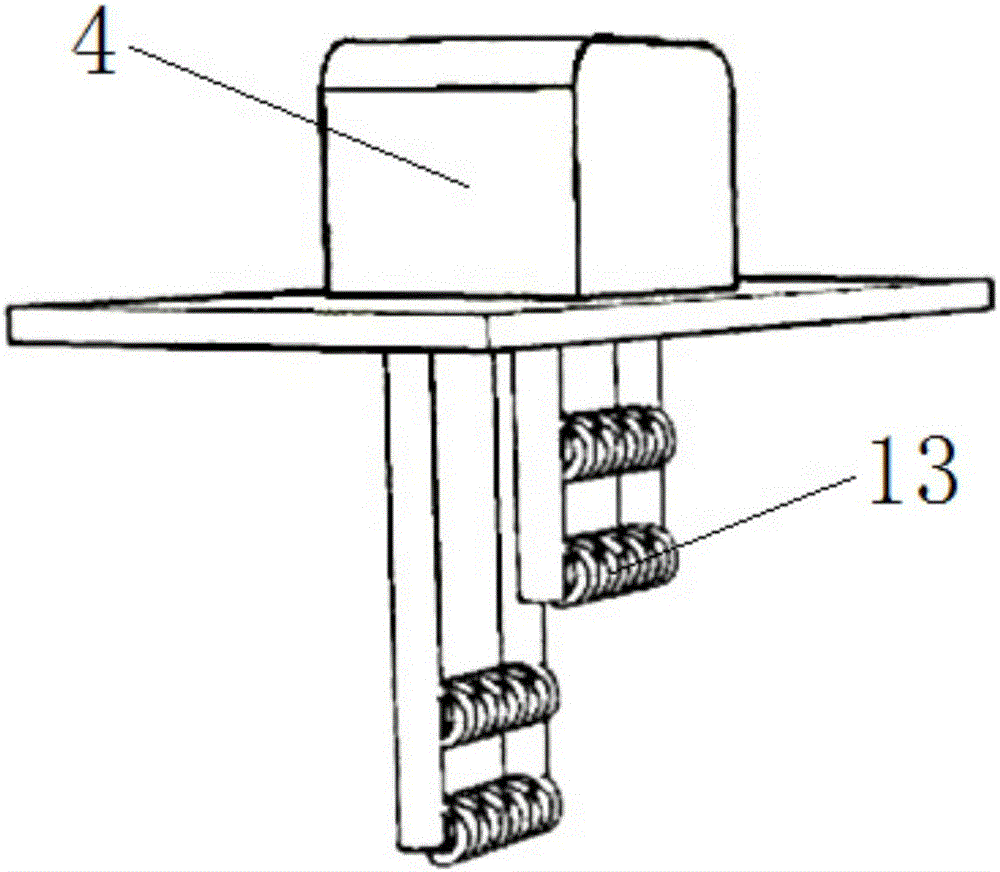

[0057] In addition, a T-s...

Embodiment 3

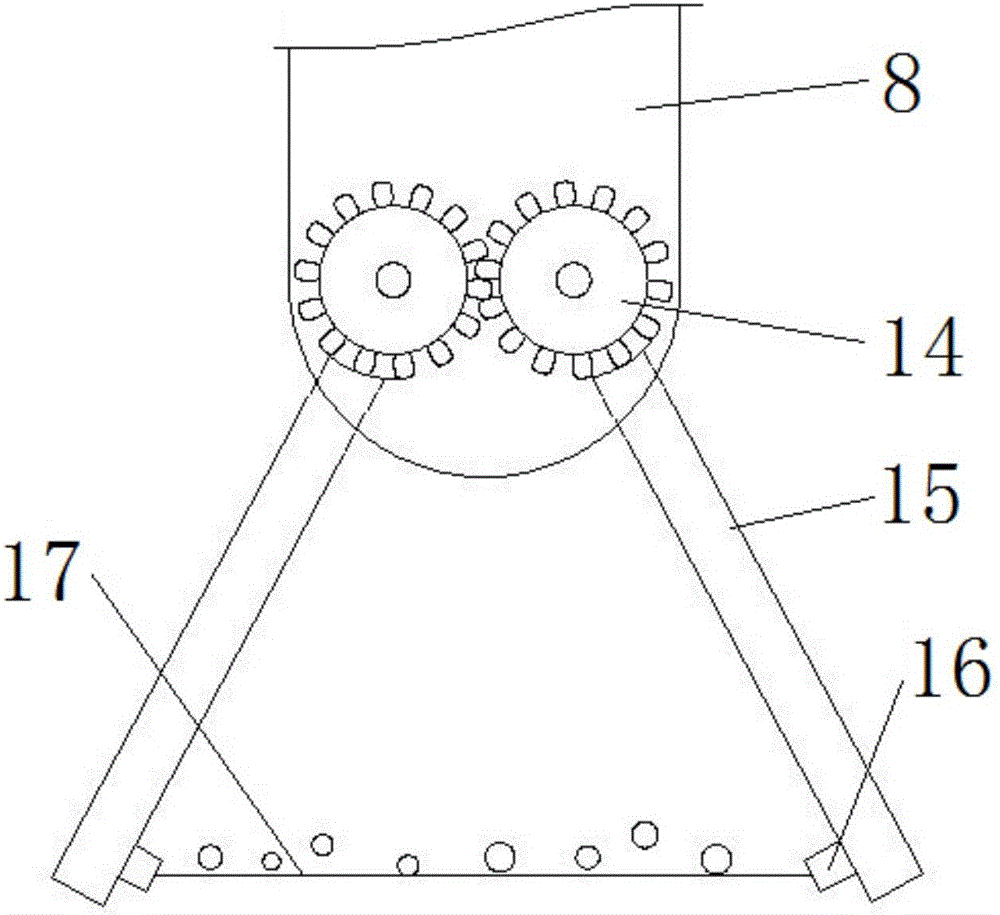

[0060] set image 3 The basic structure of a visualized large container experimental device of this embodiment is the same as that of embodiment 2, except that the heating wire fixing mechanism in the heating wire fixing and adjusting mechanism is mainly composed of a heating wire fixing frame 8 and a brace 15 Composition, the upper end of the heating wire fixing frame 8 is fixedly connected with the lifting support rod 7, two support rods 15 are arranged at the lower end of the heating wire fixing frame 8, the heating wire fixing frame 8 and the two support rods 15 form a Y-shaped structure, a Y-shaped structure The upper opening is used to fix the boiling pool heating wire 17, and the opening angle of the Y-shaped structure can be adjusted, which is suitable for fixing boiling pool heating wires of different diameters and lengths, and it is convenient to adjust the boiling pool heating wire to a horizontal state.

[0061] The other end of the support rod 15 is provided with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com