An automatic plugging and unplugging device for connecting wires

A technology of automatic plugging and unplugging devices, which is applied in the connection/disconnection direction of the connection device, can solve the problems of waste, tediousness, and impact on the production process of the display, and achieve the effect of simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

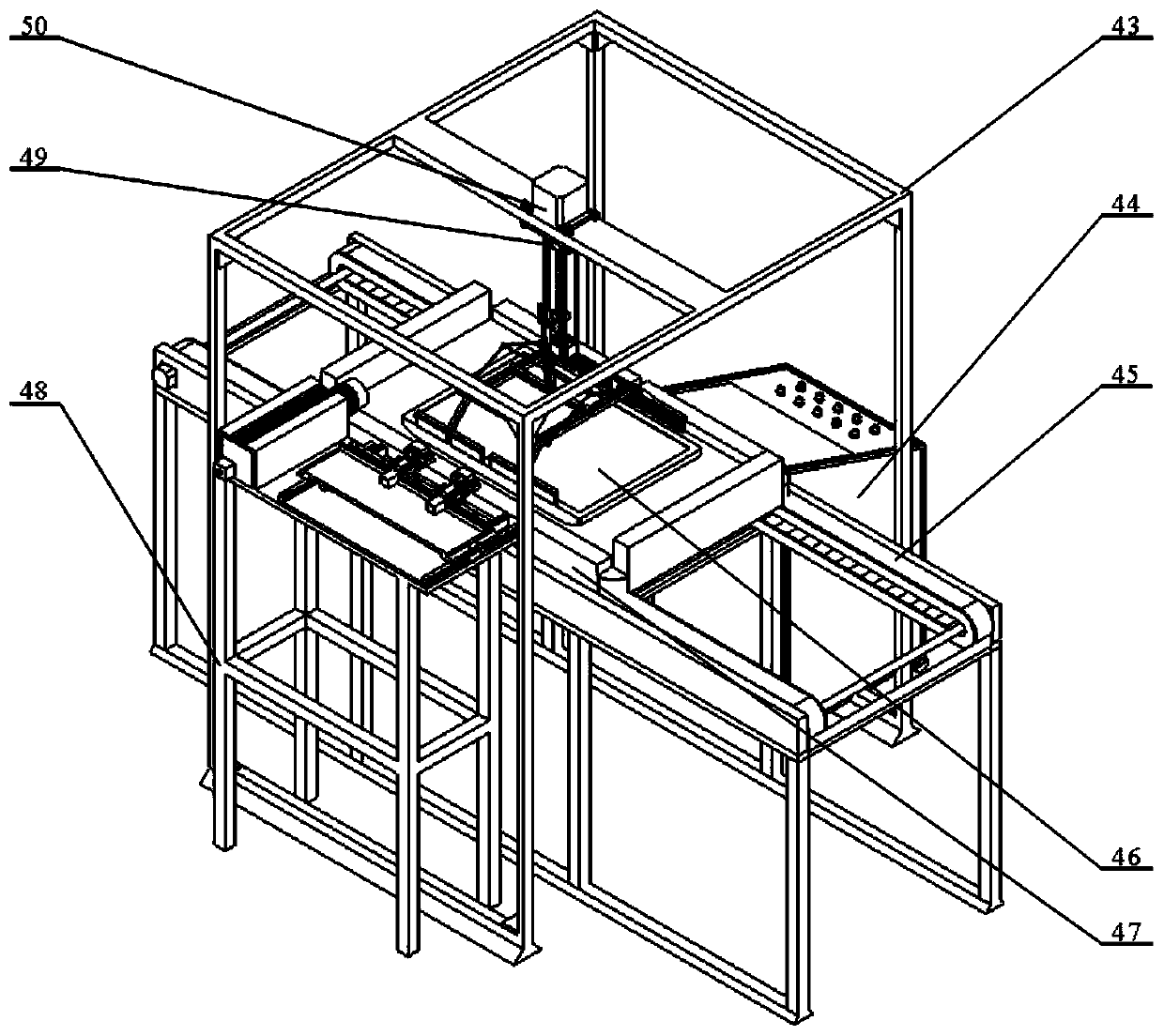

[0039] Embodiment 1: as Figure 1-23 As shown, a connecting wire automatic plugging device includes a frame 43, a transmission system 45, a plugging device 48, a grabbing device 49, and a stepping motor III 50; the frame 43 is used to install the grabbing device 49;

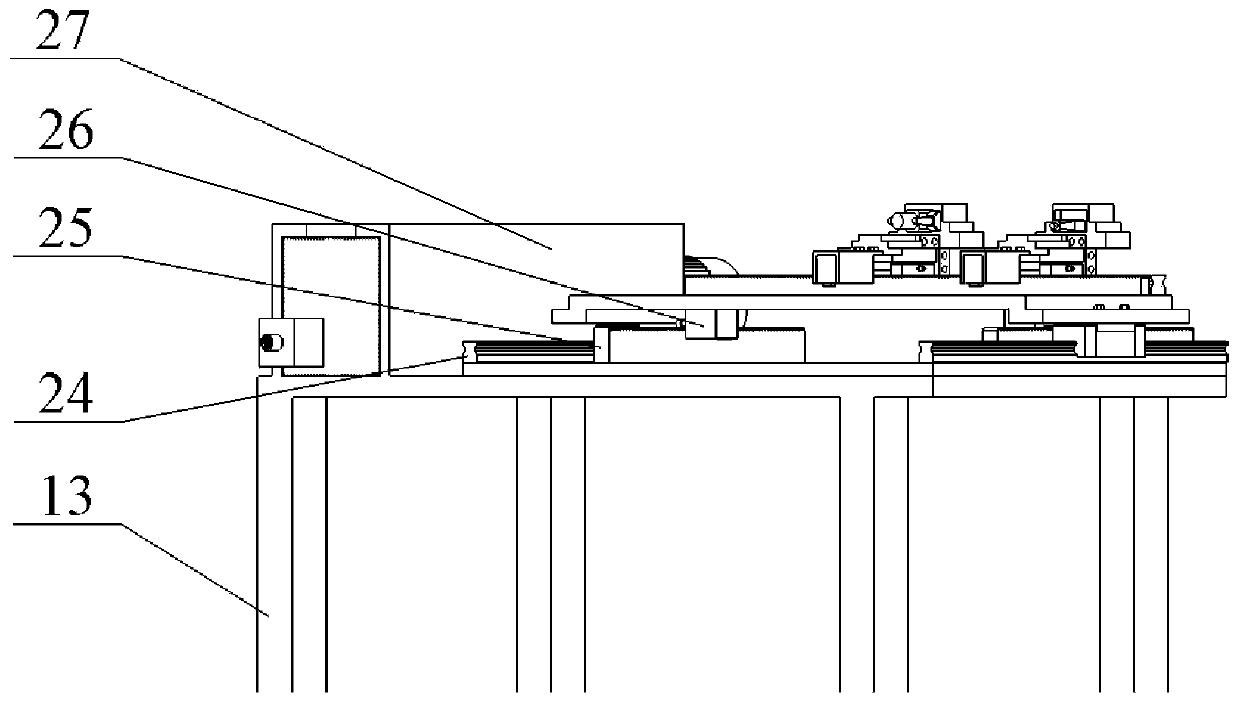

[0040] The conveying system 45 is used to convey the items to be plugged; the plugging device 48 is used to drive the connecting wire installed thereon to move in the X direction; it is used to drive the connecting wire installed thereon to move in the Y direction, In this way, the connecting wire and the item to be plugged can be plugged and unplugged; the grasping device 49 is used to provide power from the stepper motor III 50 to move in the Z direction, thereby realizing the grasping of the item to be plugged and unplugged.

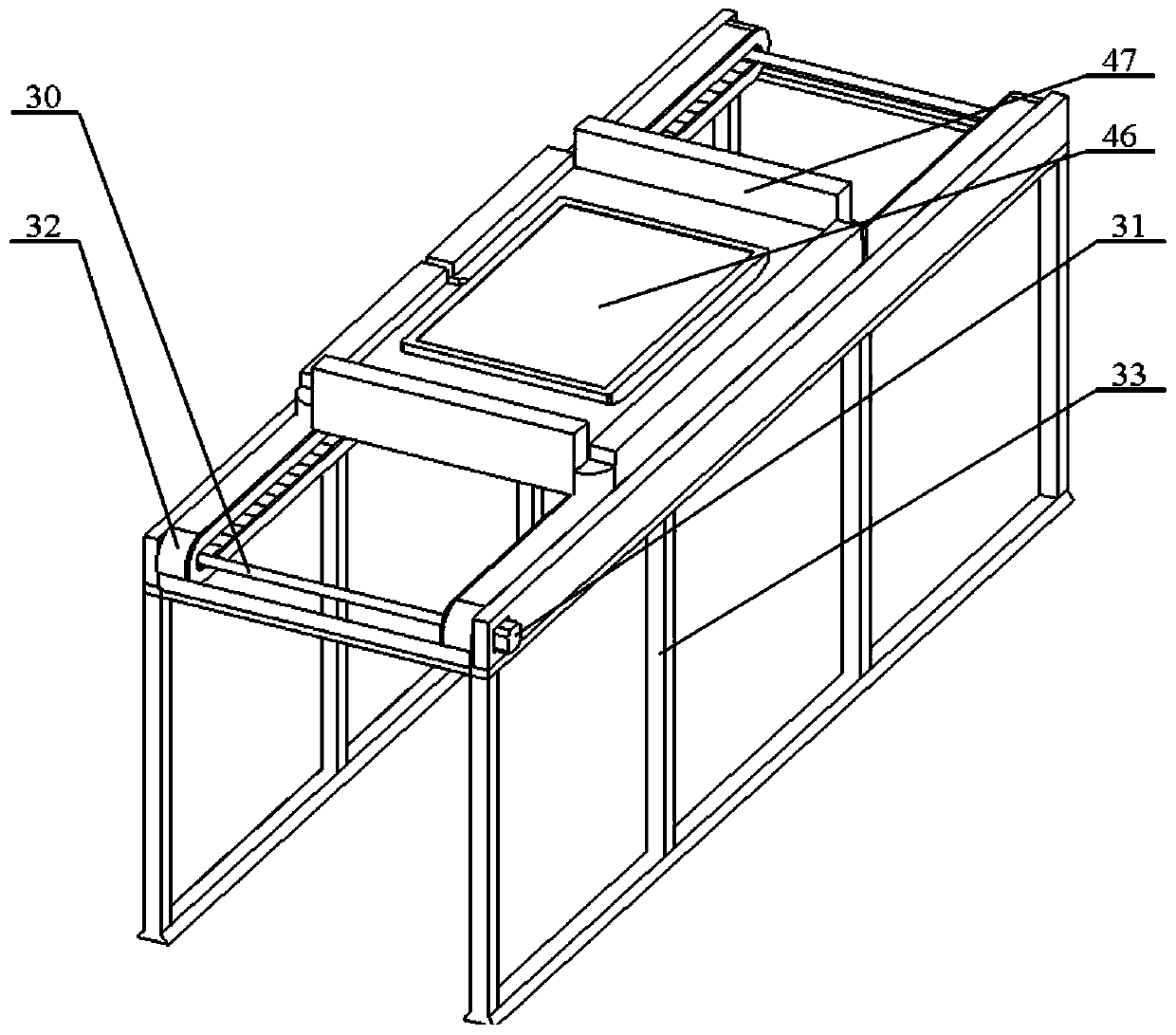

[0041] Further, the transmission system 45 can be set to be composed of the transmission shaft 30, the drive motor 31, the conveyor belt 32, the support frame 33 and the storage table 47...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com