Unhooking and resetting device

A technology of reset device and plug-in device, which is applied in fixing devices, fluid pressure actuating devices, transportation and packaging, etc., can solve the problems of high risk, labor-intensive, complicated decoupling and reset process, etc., so as to improve the test safety. The effect of simplifying the decoupling reset process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

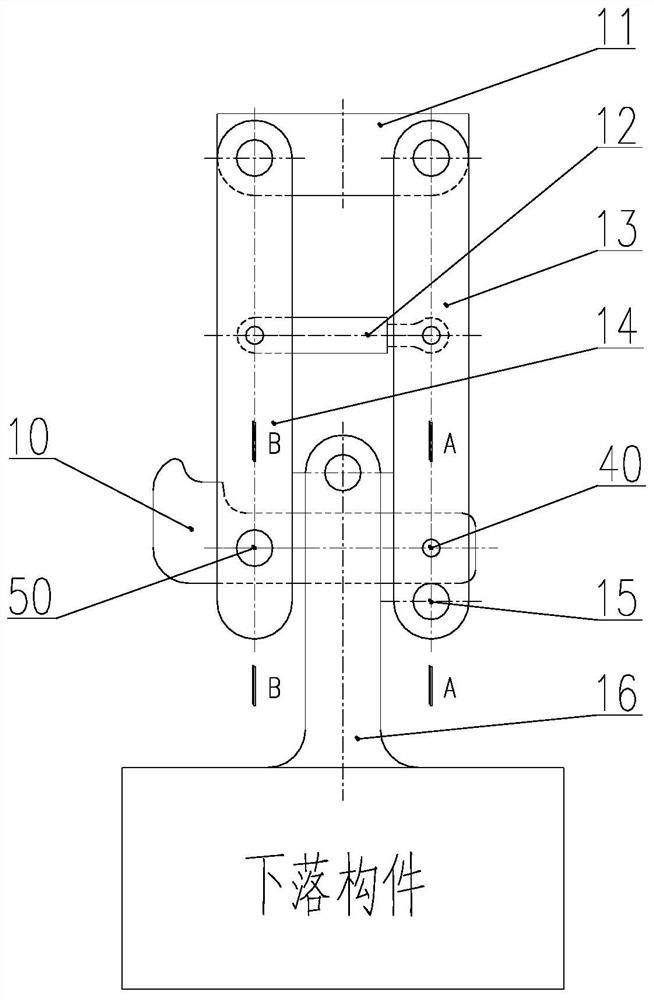

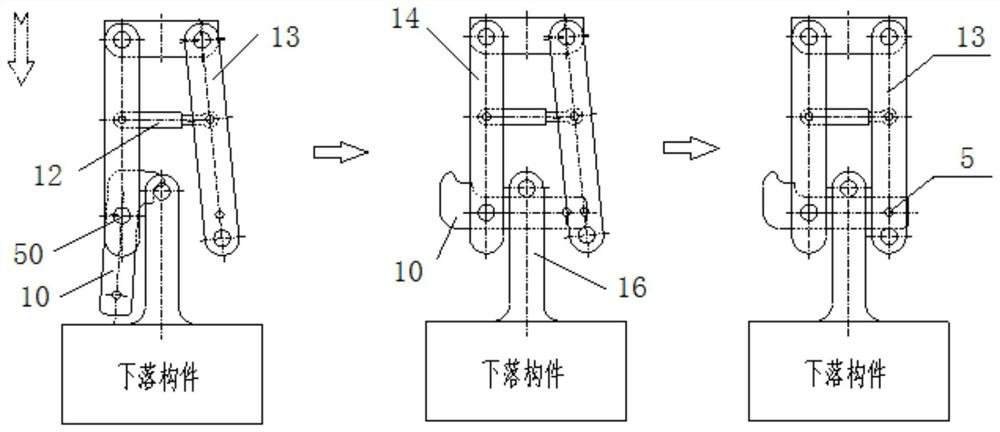

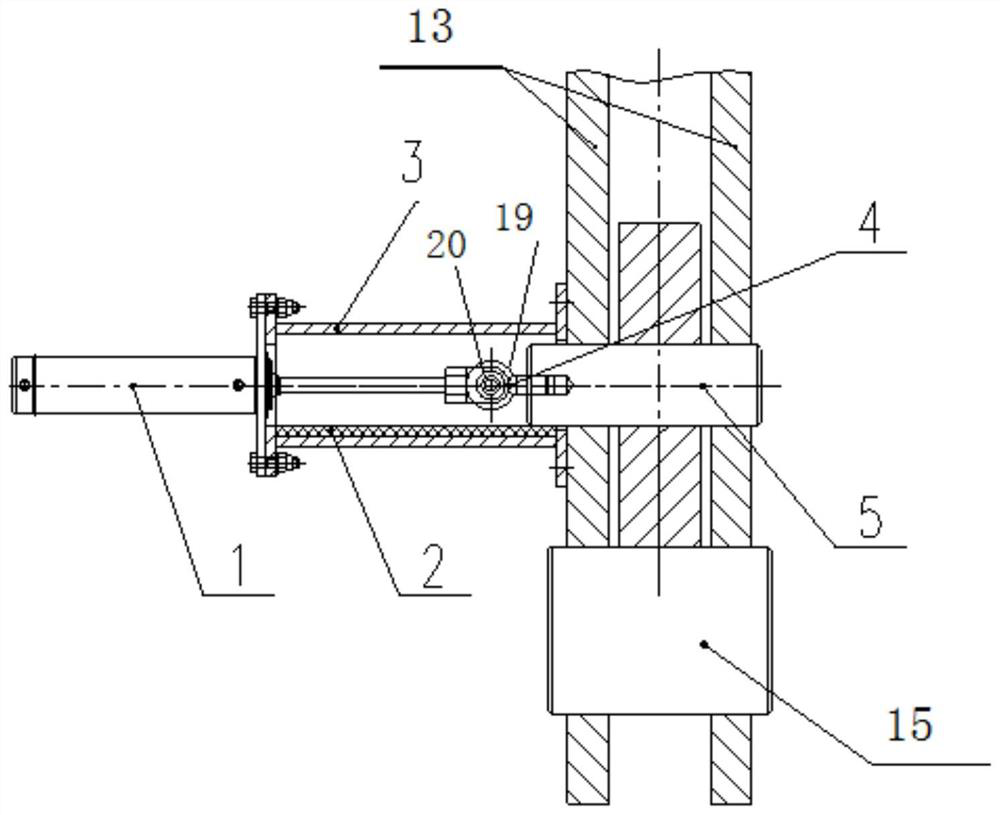

[0038] Such as Figure 1-Figure 8 As shown, a decoupling resetting device of the present invention includes: a safety pin insertion device 40, a swing beam rotation device 50 and a corresponding hydraulic control system, and also includes two front and rear swing arms I13, two front and rear swing arms II 14, There is a fixed ear plate 11 in the middle, and an opening and closing hydraulic cylinder 12 in the middle; the top of the swing arm I13 and the swing arm II 14 are connected together by the fixed ear plate 11 (the front and rear two swing arms I13 and the left end of the fixed ear plate 11 in the middle are connected by a pin The shaft is fixedly connected, and the front and rear two swing arms II14 and the fixed ear plate 11 right ends in the middle are also fixedly connected by pin shafts); the middle part of the swing arm I13 and the swing arm II 14 is respectively connected with the two ends of the opening and closing hydraulic cylinder 12 (the swing arm I13 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com