Multilayer paper bag for fruits

A paper bag and fruit technology, applied in the field of fruit production technology and fruit paper bags, can solve the problems of reducing the plane area of paper bags, different sizes of paper bags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

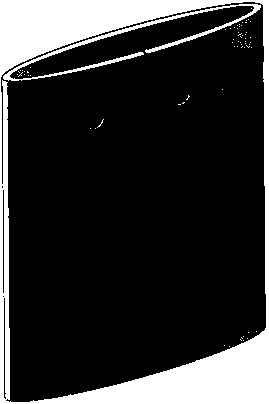

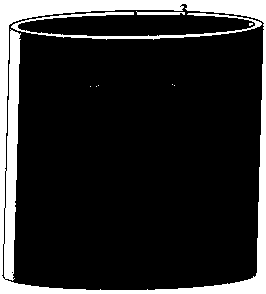

[0027] Figure 1-2 , Figure 8-11 , the basic structure of a paper bag with holes in the outer layer of a multi-layer fruit paper bag. The upper end of the paper bag is an open end, and the outer layer of the multi-layer paper bag has holes. The paper bag may present a single M-shaped or multiple M-shaped folded paper bags. It is mainly aimed at bagging machines that use pneumatic opening or pneumatic working methods to solve the problem of difficult bagging of multi-layer paper bags. The outer layer of the paper bag is provided with one or more holes, and the function of the holes is mainly air holes. It can solve the opening and conveying problems of paper bags. Generally speaking, except for the innermost layer, multi-layer paper bags have air holes, so that when the paper bag is opened, the pneumatic suction cup can open the multi-layer paper bag at one time; For other layers, open the pores to the sub-outer layer and so on.

[0028] Figure 1-12 , the center positio...

Embodiment 2

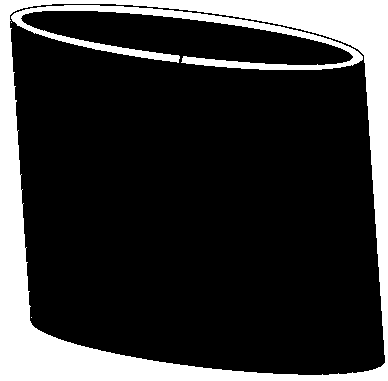

[0037] image 3 , Figure 4 , Figure 9 , Figure 12 , a basic structure in which the inner layer of a multi-layer fruit paper bag is provided with metal sheets or wires, the upper end of the paper bag is an open end, the inner layer of the multi-layer paper bag is provided with metal sheets or wires; , the side is a one-shaped paper bag or a single M-shaped or multiple M-shaped folded paper bag. It is mainly aimed at bagging machines with magnetic opening or magnetic working methods to solve the problem of difficult bagging of multi-layer paper bags. As far as the opening method is concerned, as long as the metal sheet is set on the innermost layer, the multi-layer paper bag can be opened by using the magnetic principle. For the paper bag itself and the bagging machine, the technology becomes relatively simple, and the mechanical cost is also low. Becomes relatively low, this feature is also very worth implementing, this is the main difference from the implementation colu...

Embodiment 3

[0040] Image 6 , 11 , 12. A multi-layer fruit paper bag, the positioning holes or grooves and the upper edge are provided with tear lines; the paper bag can be single-layer or multi-layer. The purpose of setting the tear-off line on the positioning hole of the single-layer or multi-layer paper bag is to remove the paper bag from the automatic bagging equipment and simplify the bagging process of the automatic bagging equipment. With the tear-off line, the paper bag can be directly removed from the positioning device. Tear up and down, save unnecessary other links. Generally speaking, the positioning hole passes through the multi-layer paper bag, and the processing method is the same as that of the single-layer paper bag. It does not need to consider whether the separation and position of the multi-layer paper bag, the opening and sealing become relatively easy and simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com