A new type of propeller deflector

A diversion device and propeller technology, which is applied in the field of ships, can solve the problems of underwater water plants and other sundries easily stuck in the pipe, affecting the normal navigation of the ship, and the ship's navigation resistance is large, so as to reduce the separation of water bodies, improve the efficiency of the propeller, even flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

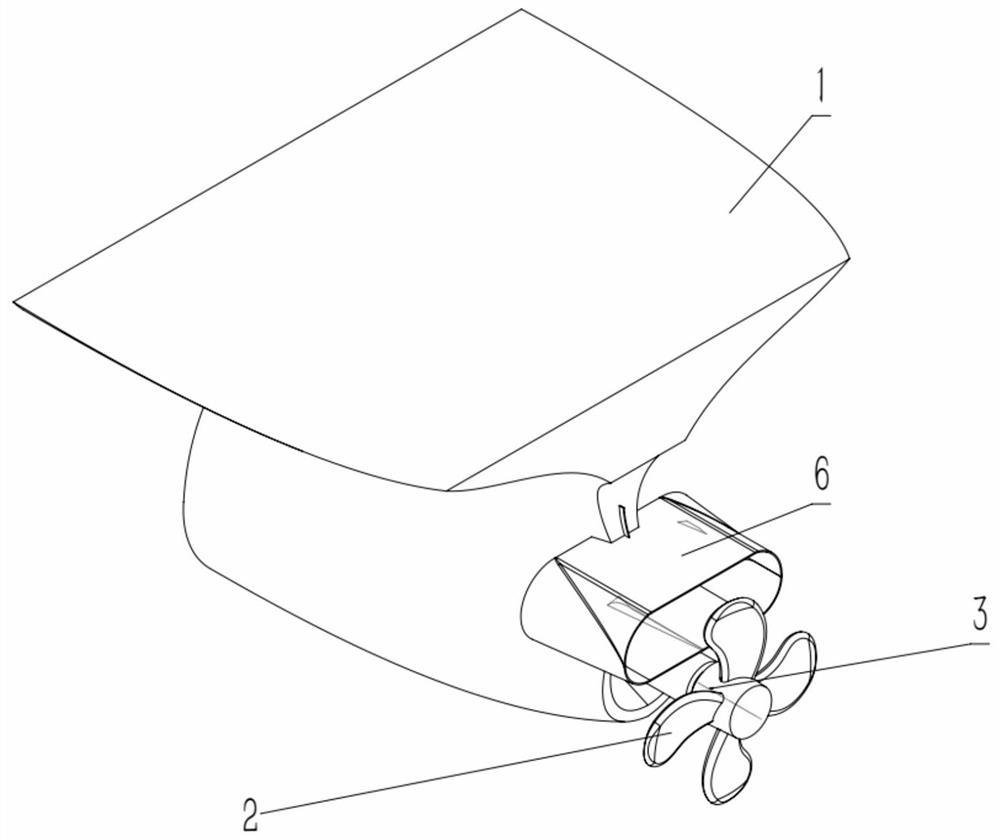

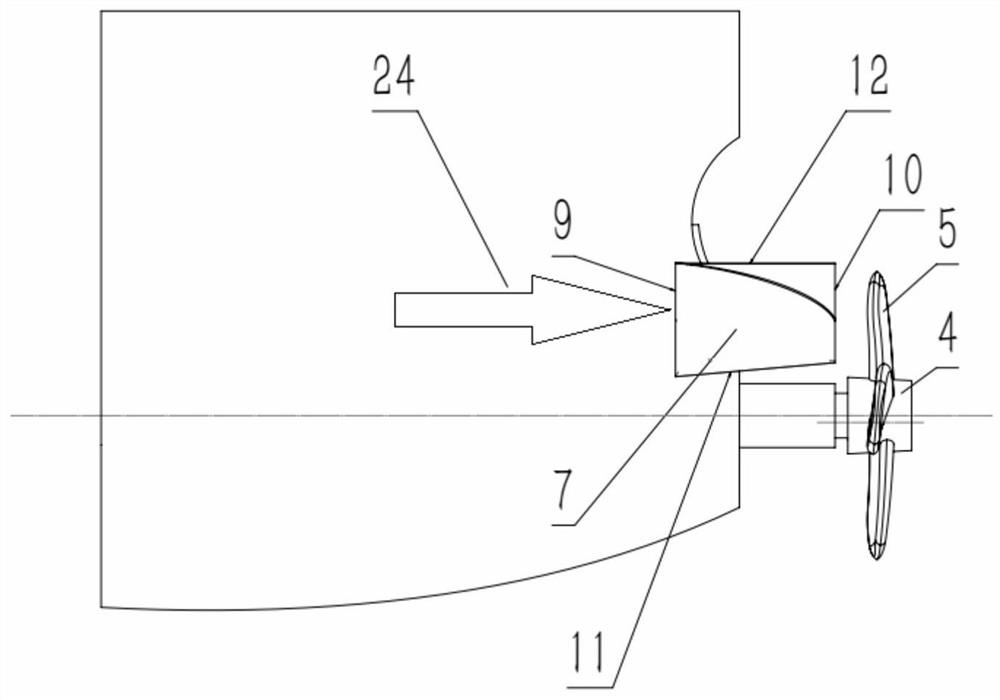

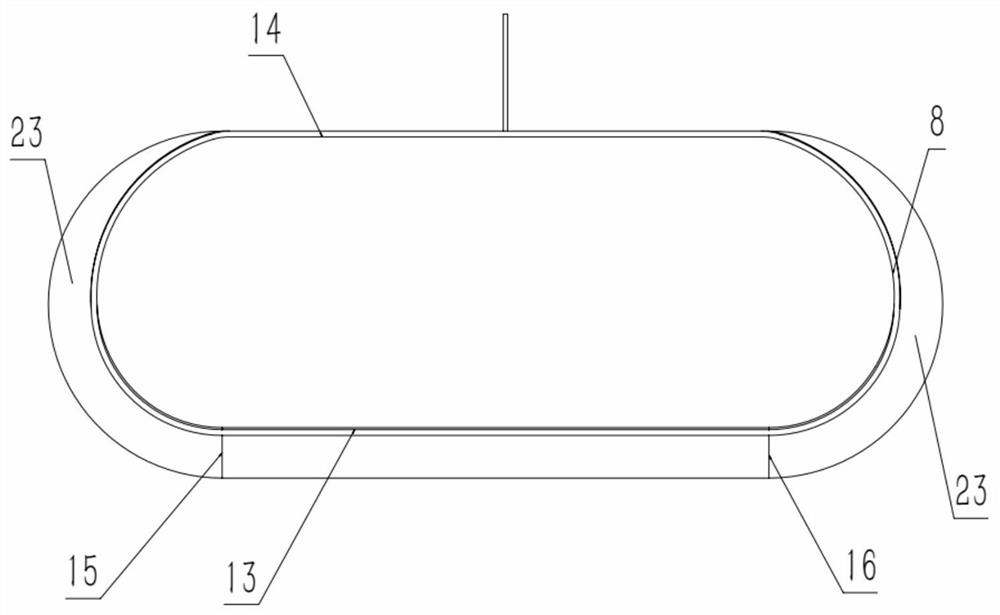

[0018] Example 1, such as Figure 1~7 As shown, a novel propeller deflector includes a hull 1 and a propeller 2 on the rear side of the hull. The upper side of the propeller 2 is provided with a guide tube 6. The guide tube 6 includes a front end surface, a rear end surface, an upper end surface, and a lower end surface. , left and right sides 23, the two ends of the cross section of the front end of the draft tube 6 are semicircular, straight sides are between the semicircular sections of the front end of the draft tube, the cross-sectional shape of the rear end of the draft tube 6 is the same as that of the front end of the draft tube The shape of the surface is the same, the cross-sectional area of the rear end face of the draft tube 6 is less than the cross-sectional area of the front end face of the draft tube 6, the upper end surface of the draft tube 6 is a horizontal plane, and the lower end surface of the draft tube 6 and the outer walls of the left and right sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com