Auxiliary tool and assembly method for glass bead assembly

A technology for auxiliary tools and assembly holes, which is applied in the coupling of optical waveguides and the assembly/disassembly of contacts, etc., which can solve problems such as visual fatigue and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

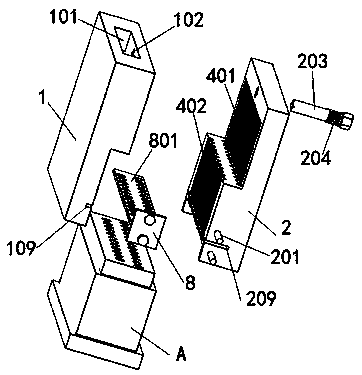

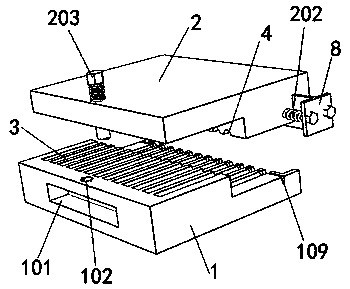

[0044] refer to figure 1 , figure 2As shown, one embodiment of the present invention is an auxiliary tool for glass bead assembly, comprising a main carrier 1 and a sub-carrier 2, the main carrier 1 and the sub-carrier 2 are L-shaped, and are used by the sub-carrier 2 The main carrier 1 is covered; the main carrier 1 and the sub-carrier 2 are rectangular after being covered.

[0045] The main carrier 1 is provided with a mounting channel 3, which is used to correspond to the assembly hole of the connector A by the mounting channel 3; the connector A is an existing connector, and the secondary carrier 2 is provided with a mounting channel. 3, the matching limiting channel 4 is used to form a tunnel by the arrangement channel 3 and the limiting channel 4.

[0046] Among them, the aperture of the arrangement channel 3 corresponds to the aperture of the limiting channel 4, and the formed channel matches the size of the glass bead / signal pin; when the glass bead / signal pin is p...

Embodiment 2

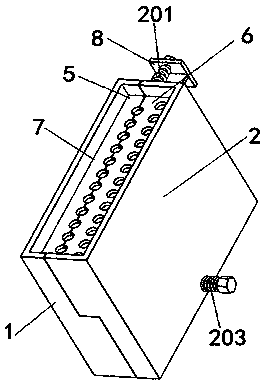

[0049] Based on the above examples, refer to Figure 4 As shown, in another embodiment of the present invention, the secondary carrier 2 is provided with a second limiting groove 209, and the main carrier 1 is provided with a first limiting groove 109 corresponding to the second limiting groove 209, The first limiting groove 109 and the second limiting groove 209 constitute a baffle groove 9 , and a baffle 8 is provided on one side of the insertion groove 7 for inserting the baffle 8 into the baffle groove 9 .

[0050] Wherein, the groove thickness of the second limiting groove 209 is the same as that of the first limiting groove 109. After the main carrier 1 and the auxiliary carrier 2 fit together, the first limiting groove 109 and the second limiting groove 209 contact and form a The baffle plate groove 9, and the groove thickness of the baffle plate groove 9 matches the thickness of the baffle plate 8, so that the baffle plate 8 can move in the baffle plate groove 9.

[0...

Embodiment 3

[0057] Based on the above examples, refer to Figure 7 , Figure 9 As shown, another embodiment of the present invention is that, in order to be better applicable to the two-row hole connector A, the above-mentioned row installation channel 3 includes a first channel 301, a second channel 302, and the first channel 301 and the second channel 302 The number is more than two, and the gap between two adjacent first channels 301 is the same, and the gap between two adjacent second channels 302 is the same.

[0058] There is a height difference between the first channel 301 and the second channel 302, the limiting channel 4 includes a third channel 401, a fourth channel 402, and a fifth channel 403, and the third channel 401 and the fourth channel 402 also have a height difference , the fifth channel 403 is placed below the fourth channel 402, and corresponds to and communicates with the third channel 401; the first channel 301, the third channel 401 and the fifth channel 403, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com