Dedusting and ash-removing pipe filter

A pipeline filter and filter technology, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as debris clogging, equipment failure, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

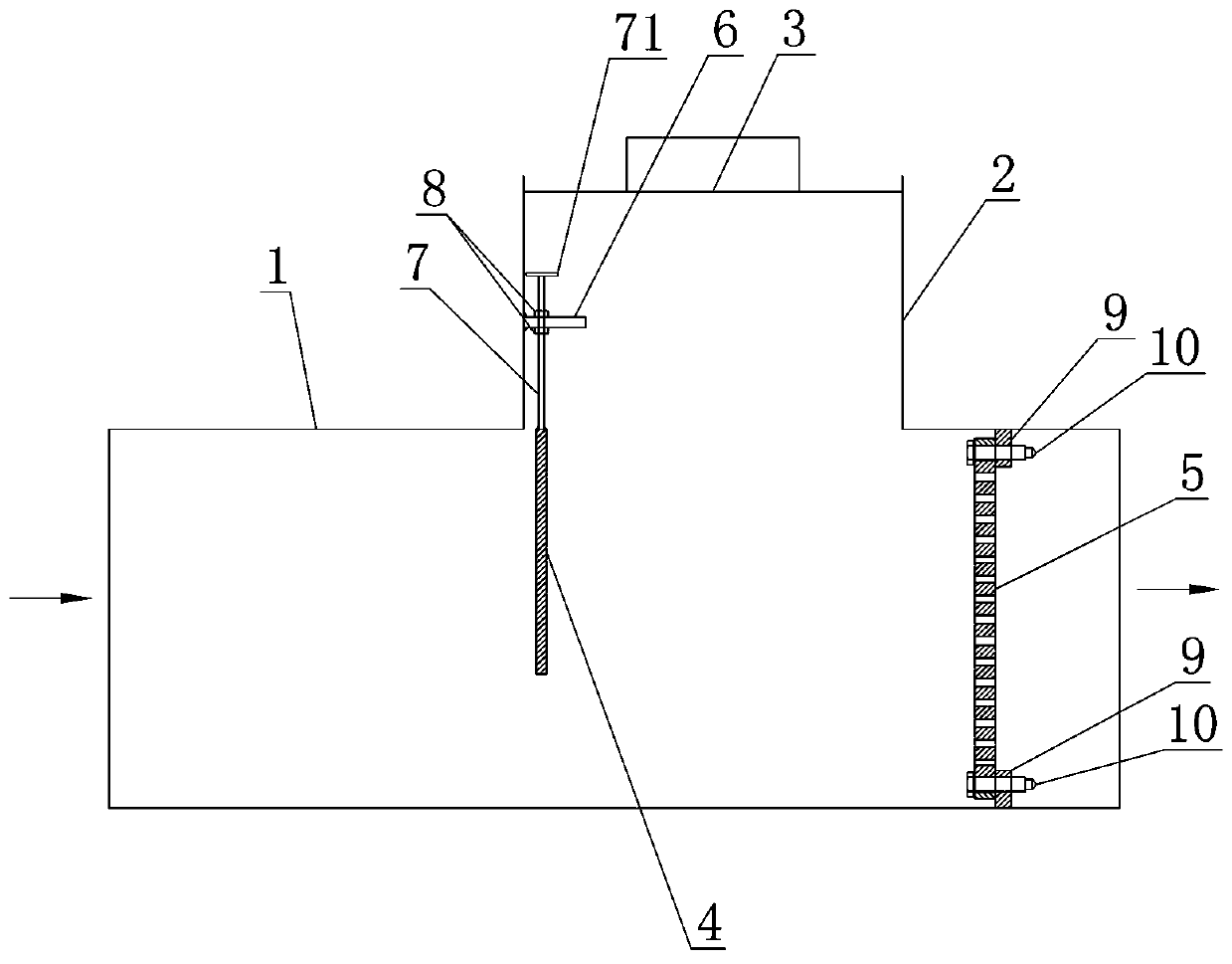

[0009] Such as figure 1 As shown, the described dust removal pipeline filter includes a tubular filter housing 1, a manhole 2 is arranged on the middle pipe wall of the filter housing 1, and a manhole 2 is covered at the manhole 2. The cover 3 is provided with a material control baffle 4 and a filter mesh 5 sequentially along the material conveying direction inside the filter housing 1, and the material control baffle 5 and the filter mesh 5 are distributed on both sides of the manhole 2. There is a material passing gap between the lower end of the material control baffle plate 4 and the inner wall of the filter housing 1, and the diameter of the filter mesh 5 is adapted to the inner diameter of the filter housing 1;

[0010] In this embodiment, the specific installation structure of the material control baffle 4 is as follows: a first fixed block 6 is fixed on the inner wall of the manhole 2 near the feed end of the filter housing 1, and is vertically fixed on the material co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com