Soil anchor rod drawing test method considering changing confining pressure conditions

A pull-out test and pull-out test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of poor repeatability, large model size, and long construction period, etc., to achieve The test results are scientific and accurate, and the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

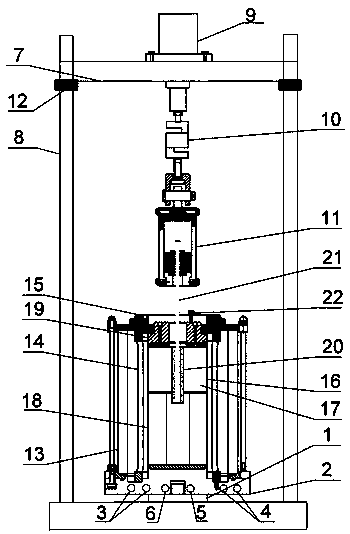

[0055] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

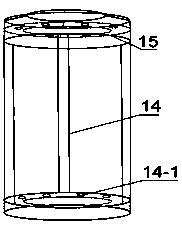

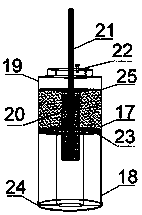

[0056] Such as Figure 1~6 As shown, a soil anchor pullout test method considering changing confining pressure conditions includes the following steps:

[0057] ⅰ. Install the lower gasket and support base

[0058] First install the lower gasket 1 at the support platform, and then install the support base 2 of the anchor pullout test device on the upper end of the lower gasket 1;

[0059] ⅱ. Install the valve on the outer wall of the support base

[0060] Install the water inlet valve 3, drain valve 4, pore pressure connection valve 5, and confining pressure connection valve 6 in the test at the interface of the outer wall of the support base 2 in sequence according to the corresponding positions;

[0061]ⅲ. Install the sample base, test sample, sample cap and ensure the tightness

[0062] Install the height-adjustable sample base 18 on the support base 2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com