Picometer optical comb, manufacturing device and manufacturing method of picometer optical comb

A technology for manufacturing devices and picometers, which is applied in special grating fields, and can solve problems such as the inability to provide different grating differences and the inability to provide picometer-level measurement benchmarks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

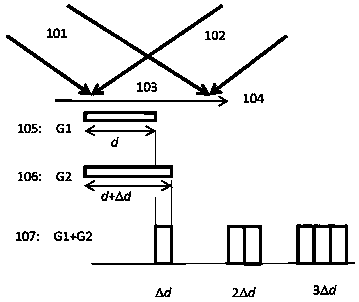

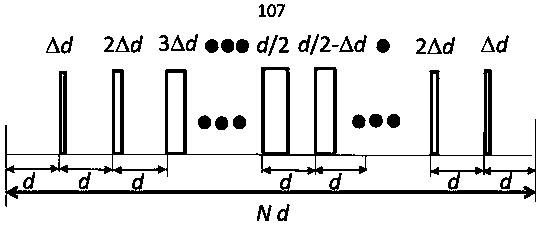

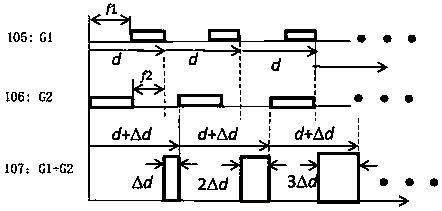

[0084] Assuming that the picometer comb is produced by two holographic exposures, the manufacturing process using holographic double-beam exposure is as follows: figure 1 As shown, the period of the grating 105 for the first exposure is d, and the period of the grating for the second exposure is d+Δd. If the second exposure and the development process are matched, the opening ratio of the second exposure grating is f1=f2= 0.5 (here the aperture ratio is defined as the ratio of the gate groove to the period), it will produce as figure 2 The picometer optical comb with continuously variable grating pitch shown in the figure, its change process in a complete picometer optical comb period N·d is as follows figure 2 shown.

[0085] Here, the aperture ratios f1 and f2 are related to the amount of secondary exposure, the degree of development, and the like. The specific numbers of f1 and f2 can be calibrated in advance by setting the relationship between exposure amount and devel...

Embodiment 2

[0088] The picometer comb may also have larger f1 and f2 caused by two exposures, such as Figure 4 As shown, at this time, there may be only one slot-shaped distribution in one cycle, for example, 411, 412, etc., and two distributions may also appear, for example, 42M and 41M appear in one cycle, which shows that both f1 and f2 In larger cases, there may be a frequency doubling effect of the picometer comb. Finally, there may be a situation where the groove width of 42N2 and 42N1 gradually increases.

Embodiment 3

[0090] It is also possible for the picometer comb to have small f1 and f2, such as Figure 5 shown. For example, f1

[0091] Of course, for the distribution of f1 and f2 in other situations, there are more possibilities.

[0092] Since we can accurately measure the periods of the first and second exposures, reaching the picometer level, through the second exposure technology and changing the period of the second exposure, by setting the difference between the grating periods during the two exposures , the precise groove shape distribution of the picometer optical comb can be obtained, wherein the width of each groove shape is relative to the groove shape of the adjacent period, and the differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com