Instantaneous frequency-based wood structure damage acoustic emission nondestructive detection method

An instantaneous frequency and non-destructive testing technology, which is applied in the direction of material analysis, measuring devices, and processing detection response signals using acoustic wave emission technology, can solve problems such as reducing material life and irreversible damage to buildings, and achieve the effect of enhancing fault characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0053]The invention provides a method for acoustic emission signal identification and stress non-destructive detection of wooden structure damage based on instantaneous frequency, aiming at evaluating the stress state in the process of wood damage by using acoustic emission technology and realizing online damage monitoring of wooden structures.

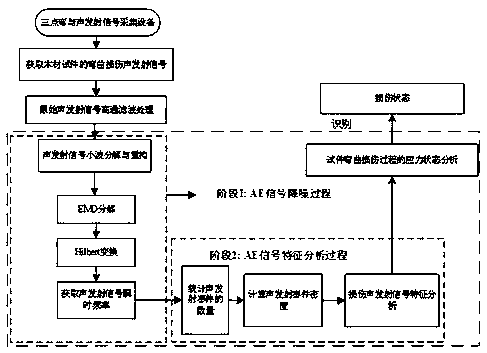

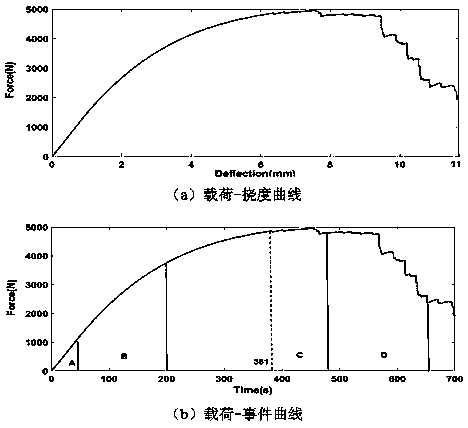

[0054] figure 1 It is a flowchart of the present invention. The steps of the present invention will be described in detail below in conjunction with the flowchart.

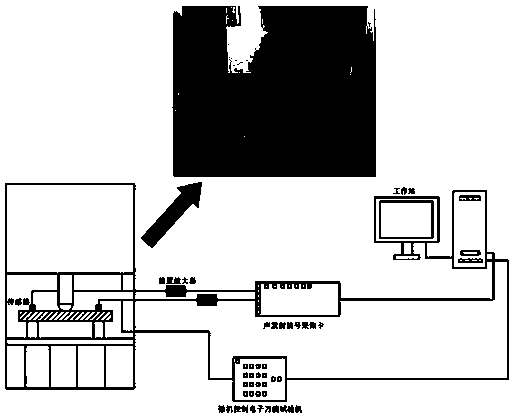

[0055] Step 1, pre-select the Yunnan pine specimens that are dried to a dry state and have no obvious defects, and collect the acoustic emission signals generated by the tested specimens under the three-point bending test;

[0056] Step 2, performing high-pass filtering and wavelet decomposition and reconstruction on the collected acousti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com