Brake master cylinder with normally-closed valve

A technology of brake master cylinder and normally closed valve, which is applied in the direction of brakes, brake transmission devices, hydraulic brake transmission devices, etc., and can solve the problems that cannot meet the energy recovery requirements of new energy vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

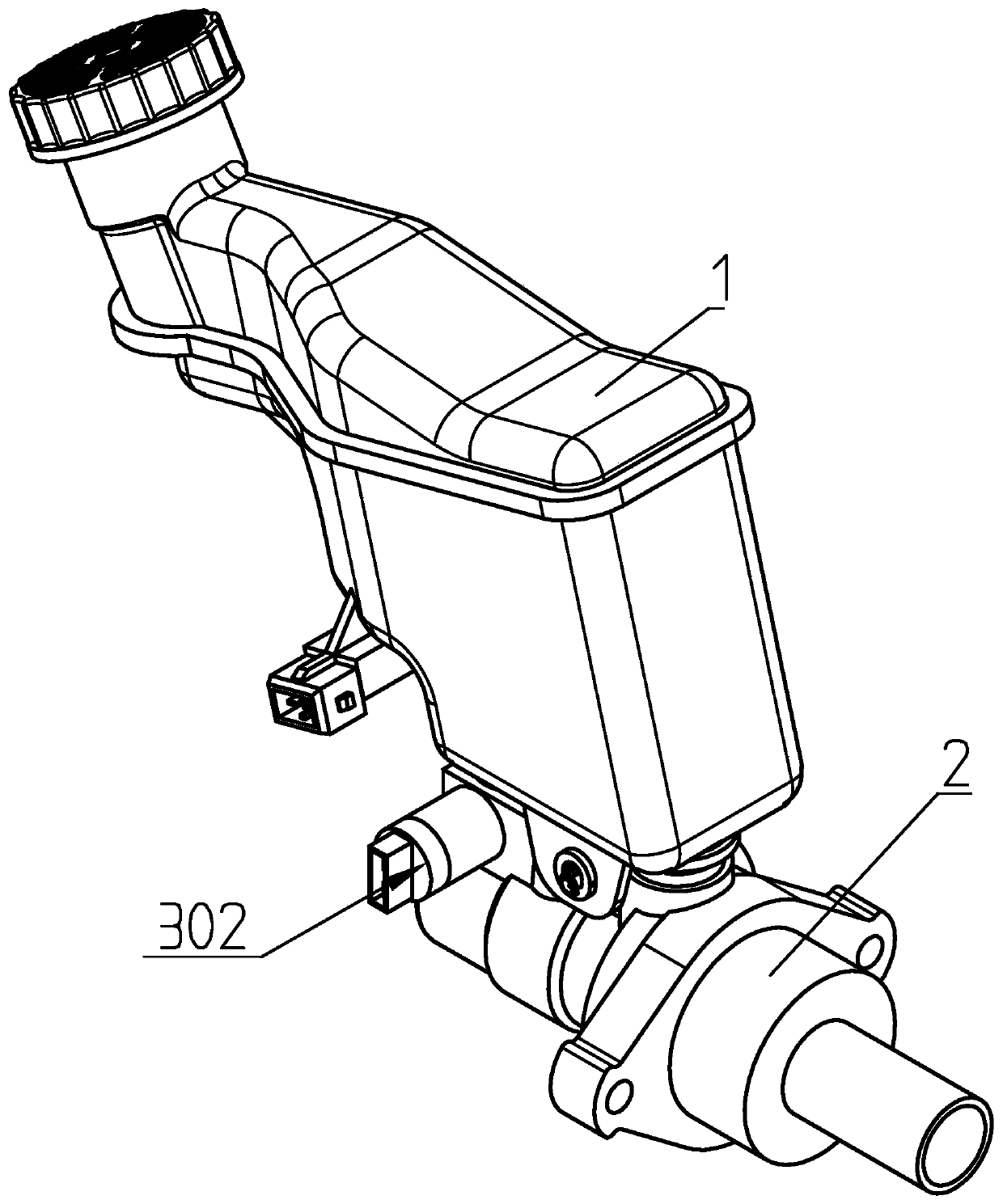

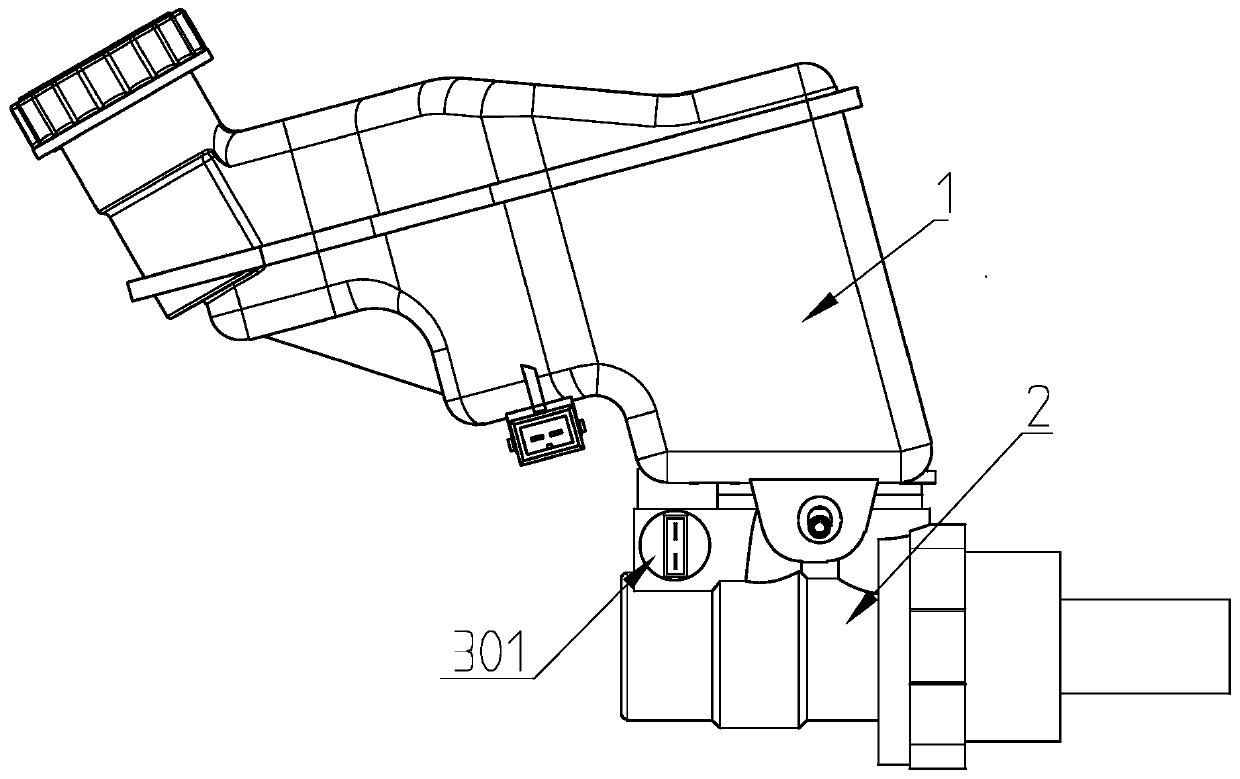

[0010] Embodiment: As shown in the accompanying drawings, this brake master cylinder with a normally closed valve mainly includes a liquid storage tank 1, a cylinder body 2, a coil 301, and a normally closed valve 302. The cylinder body 2 is connected to the liquid storage tank 1, A normally closed valve 302 is added to the cylinder body 2, and the normally closed valve 302 is opened and closed through the coil 301 provided on it to control the opening and closing, so that the excess brake fluid can be discharged back into the liquid storage tank 1 to cooperate with the whole vehicle. Brake energy recovery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com