Gas spray tube of gas water heater

A technology for gas water heaters and jet pipes, which is applied in the direction of burners, fluid heaters, gas fuel burners, etc. It can solve the problems of sealing, inability to achieve large flow, and small air intake passages, so as to achieve good sealing effect and improve the efficiency of air intake. The effect of injecting air once and reducing harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

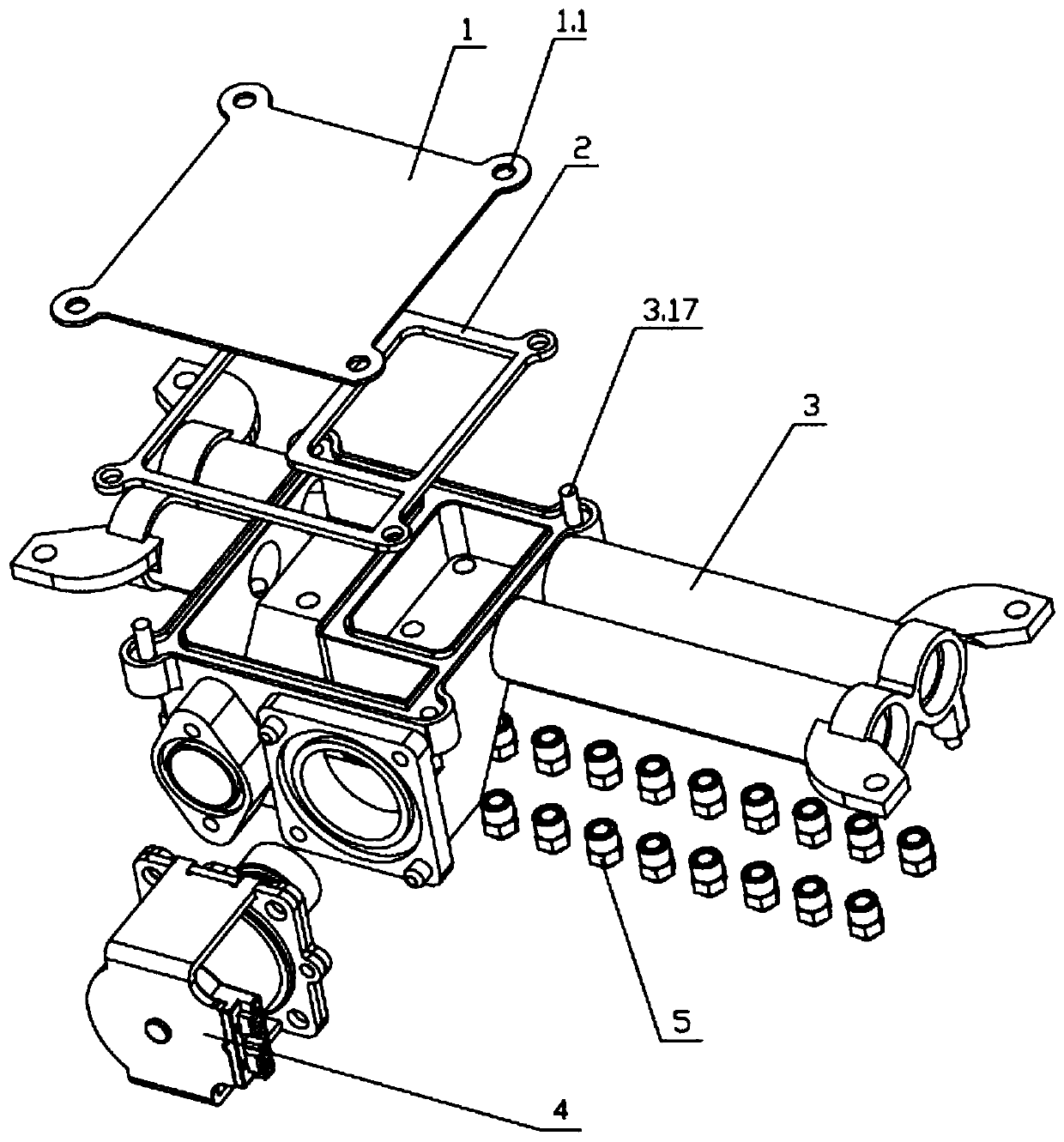

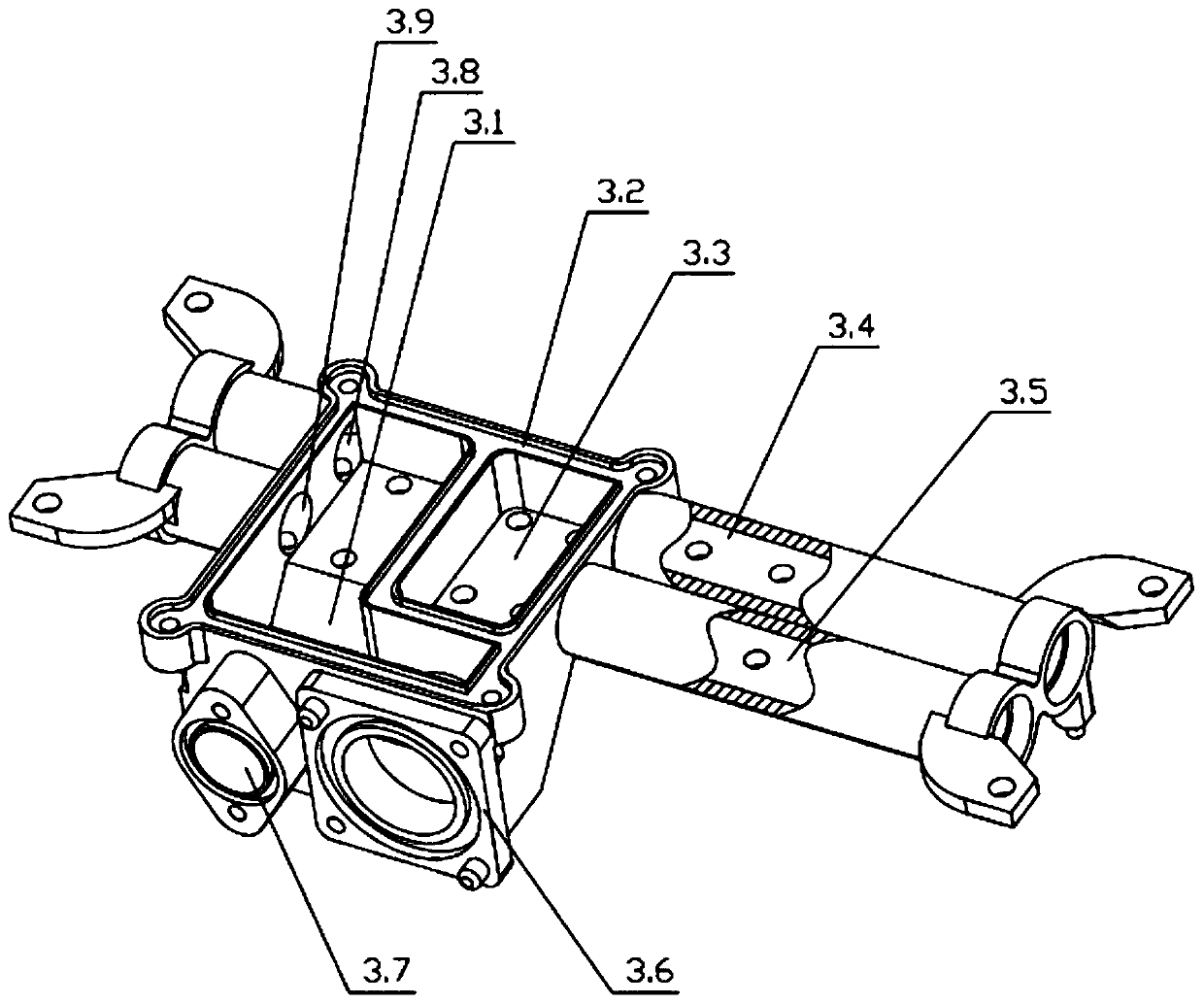

[0030] Such as figure 1 , 2 As shown, a gas injection pipe of a gas water heater includes a gas injection pipe main body 3, a first shut-off valve 4 arranged on the side of the air injection pipe main body 3, and a nozzle 5 arranged in the air injection pipe main body 3, wherein the gas injection pipe of a gas water heater It also includes a cover plate 1, a sealing member 2, and a plug 6. The plug 6 is fixed on the end of the jet pipe main body 3, and the cover plate 1 is fixed to the jet pipe main body 3 through the sealing member 2.

[0031] In this embodiment, the cover plate 1 and the sealing member 2 are added, and the internal structure of the jet pipe main body 3 can achieve a large flow rate, can improve the amount of air injected once, and then reduce the harmful gases (CO, NO) after combustion of the gas. X ).

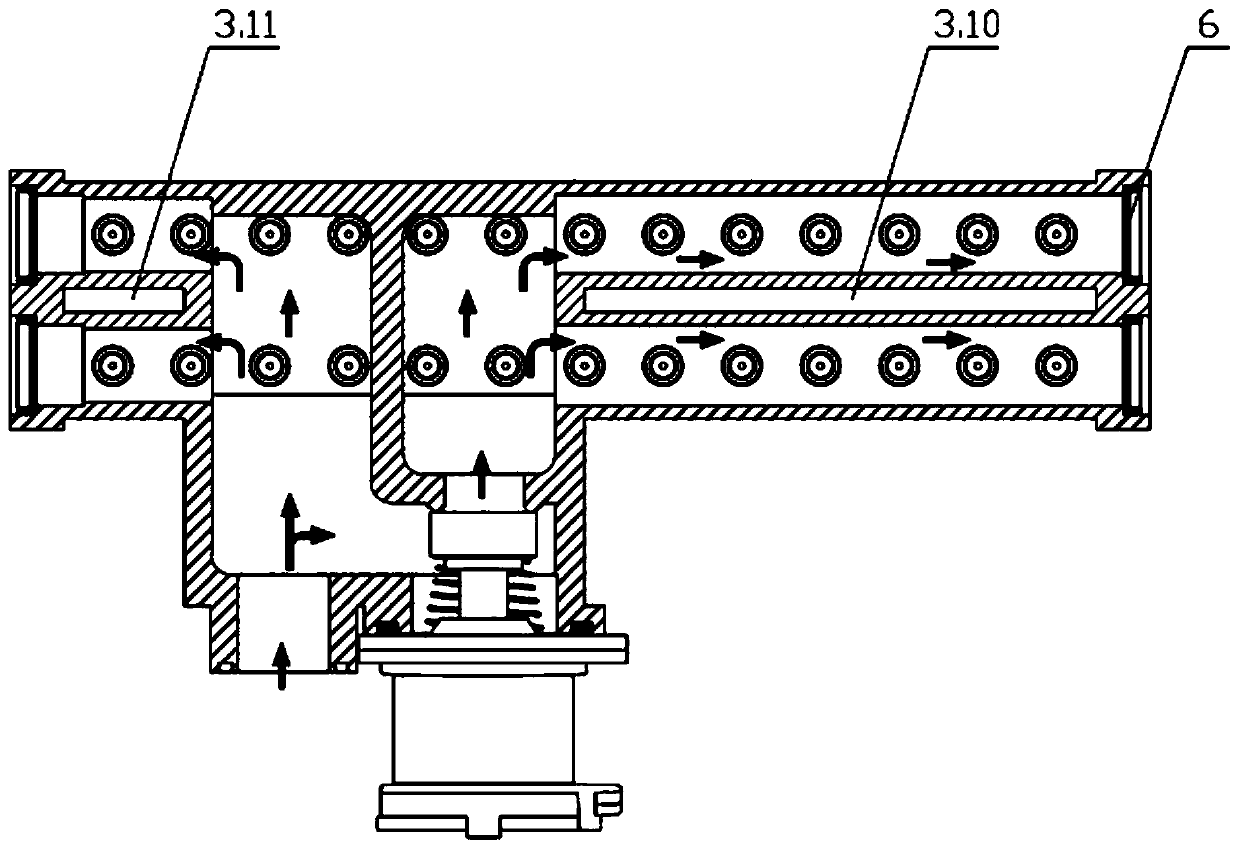

[0032] Such as figure 2 , 3 Among them, the inner cavity of the jet pipe main body 3 is provided with an air inlet channel, a first air distribution ch...

Embodiment 2

[0047] Such as Figure 4 As shown, in this embodiment, on the basis of Embodiment 1, a second cut-off valve 7 is additionally provided; the second gas distribution inlet cavity 3.12, the fifth gas distribution channel 3.13, and the sixth gas distribution channel are also added on the main body of the jet pipe. 3.14. The second cut-off valve installation platform 3.15; the fifth gas distribution channel 3.13 and the sixth gas distribution channel 3.14 are independent of each other and communicate with the second gas distribution inlet chamber 3.12; the second gas distribution inlet chamber 3.12 is connected to the normal inlet The air cavity 3.1 is connected through a valve; the second stop valve 7 is installed on the second stop valve installation platform 3.15, and controls the on-off of the valve; The channel 3.16 runs through the fifth gas distribution channel 3.13 and the sixth gas distribution channel 3.14.

[0048] The working principle of this embodiment:

[0049] Dur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap