Automatic stacking system for iron workpiece

A palletizing system and palletizing technology, applied in the field of automated production, can solve complex and changeable problems

Inactive Publication Date: 2019-09-13

徐州乾盾智能科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the complex and changeable actual application scenarios in the industry, users will need pallets that can adapt to their actual application scenarios

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0031] As an embodiment of the present invention, the rolling carrier member is a conveyor belt having an idler set.

[0032] As an embodiment of the present invention, the empty pallet conveying component is a transmission chain structure.

[0033] As an embodiment of the present invention, the empty pallet conveying component is a drive roller structure.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

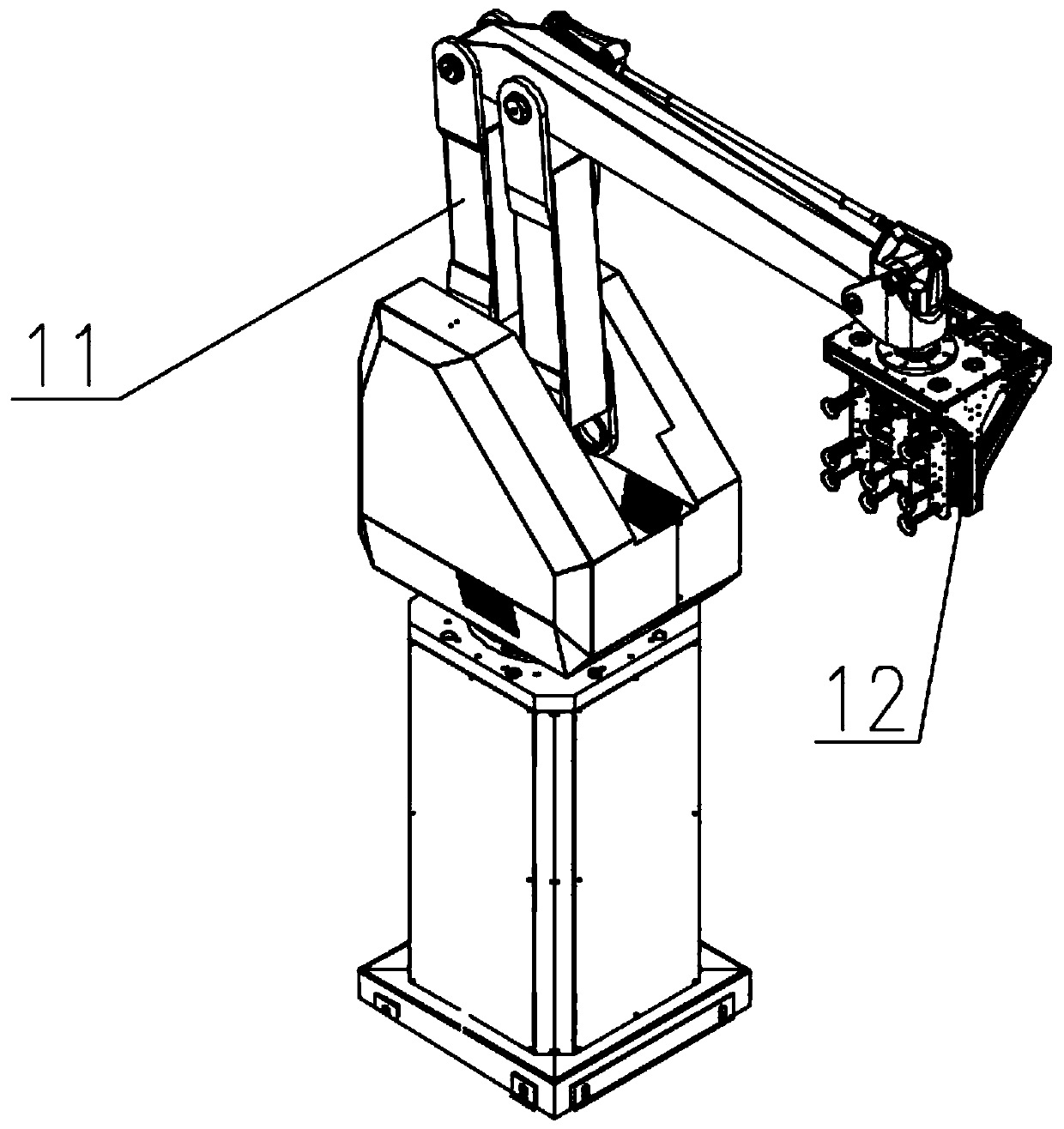

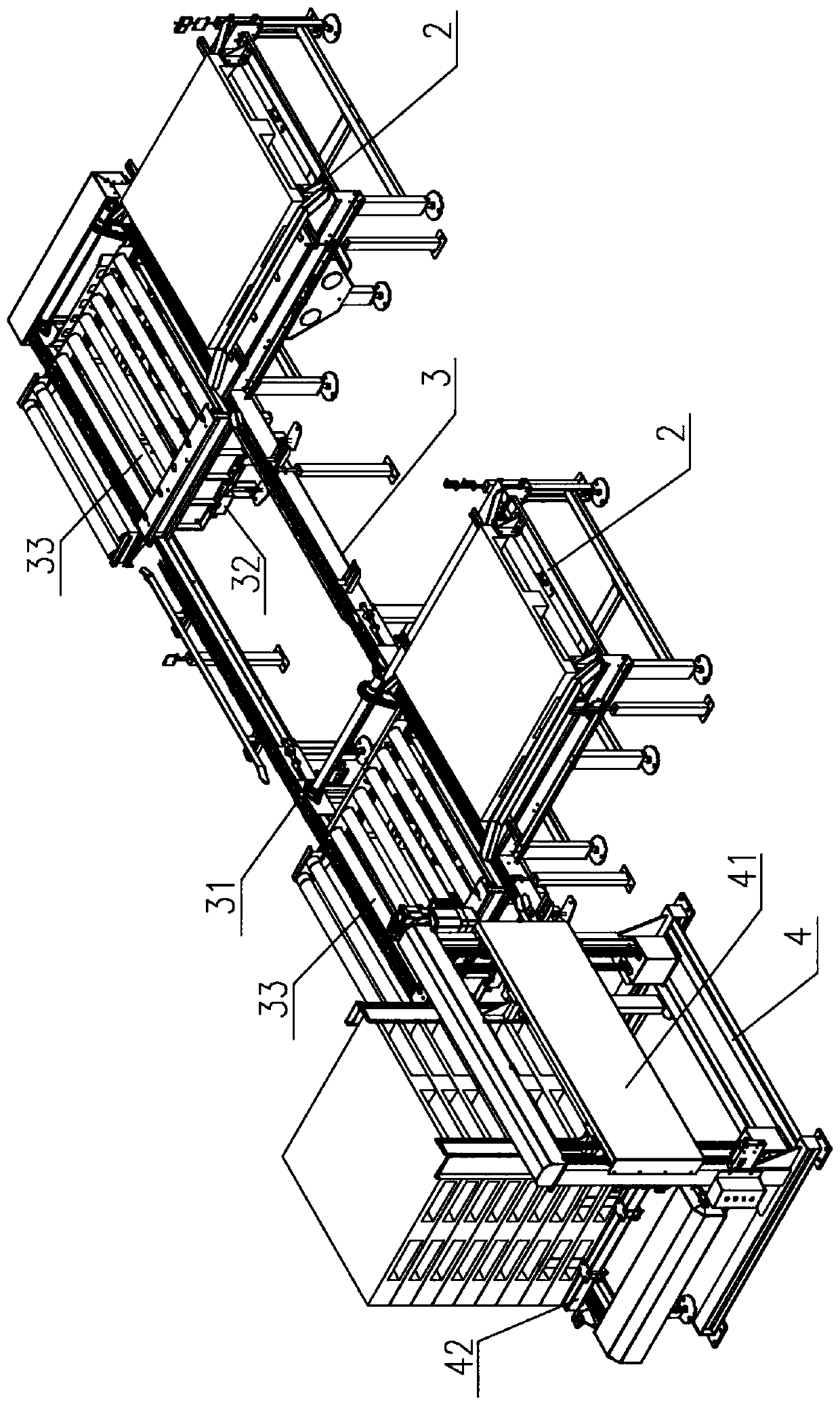

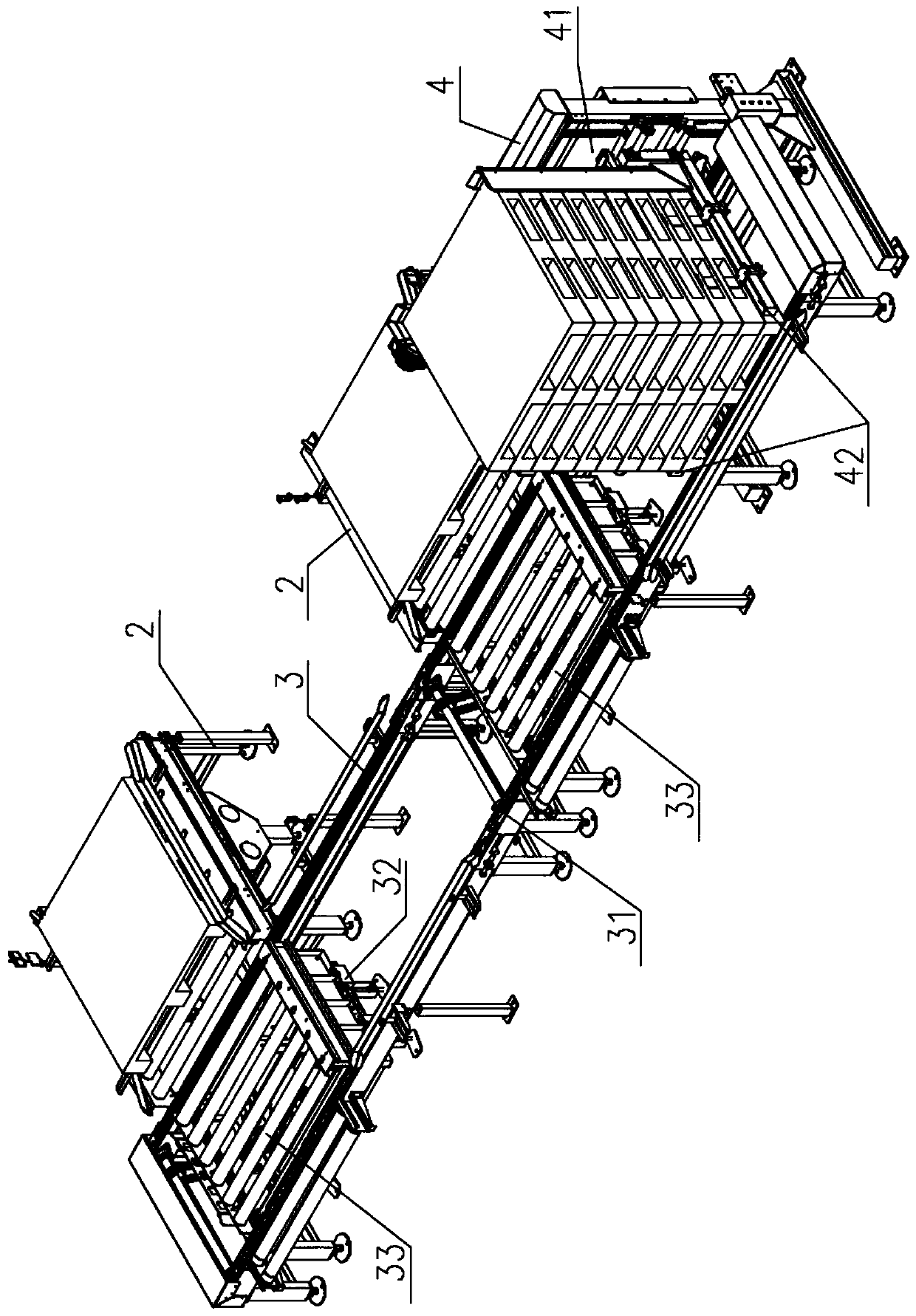

The invention discloses an automatic stacking system for an iron workpiece. The automatic stacking system comprises an empty pallet distribution part, a stacking part and a stacking electric control part; the stacking part comprises a stacking device and a stacking pallet conveyor; the stacking device comprises a stacking mechanical arm, and a stacking manipulator installed at the tail end of thestacking mechanical arm; the empty pallet distribution part comprises an empty pallet conveyor device and an empty pallet bin, and the empty pallet conveyor device is arranged in front of the stackingpallet conveyor, and comprises an empty pallet conveyor installed on an empty pallet conveying underframe, and a pallet jacking and transfer conveyor; and the stacking electric control part comprisesa stacking control circuit and an empty pallet distribution loop. According to the automatic stacking system for the iron workpiece, on the premise of limited space, automatic supply of pallets on aplurality of stations can be achieved, and the automatic stacking system is especially suitable for centralized stacking of batch products.

Description

technical field [0001] The invention relates to a stacking system, in particular to a system suitable for automatic stacking of iron workpieces with regular shapes such as iron tanks and iron boxes, and belongs to the technical field of automatic production. Background technique [0002] The core of automated production is orderly production. At present, most of the known robotic palletizing systems are used to realize the palletizing function with a single function. With the continuous development of social productivity, the demand for various new and multi-functional automated palletizing and conveying systems is increasing. , The automatic robot palletizing system integrating shaping, testing, weighing, screening and palletizing is produced in response to actual production needs. [0003] At present, the common pallet patterns in the industry include square and irregular pallet patterns. Among them, the pallet pattern is the stacking pattern of pallets, which determines h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): B65B5/10B65B43/42B65B35/16

CPCB65B5/105B65B35/16B65B43/42

Inventor 李康

Owner 徐州乾盾智能科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap