Full-hydraulic humanoid manipulator

A humanoid, manipulator technology, applied in the field of manipulators, can solve the problems of difficulty in precise adjustment, the product cannot have a good clamping effect, and the control movement accuracy is not enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

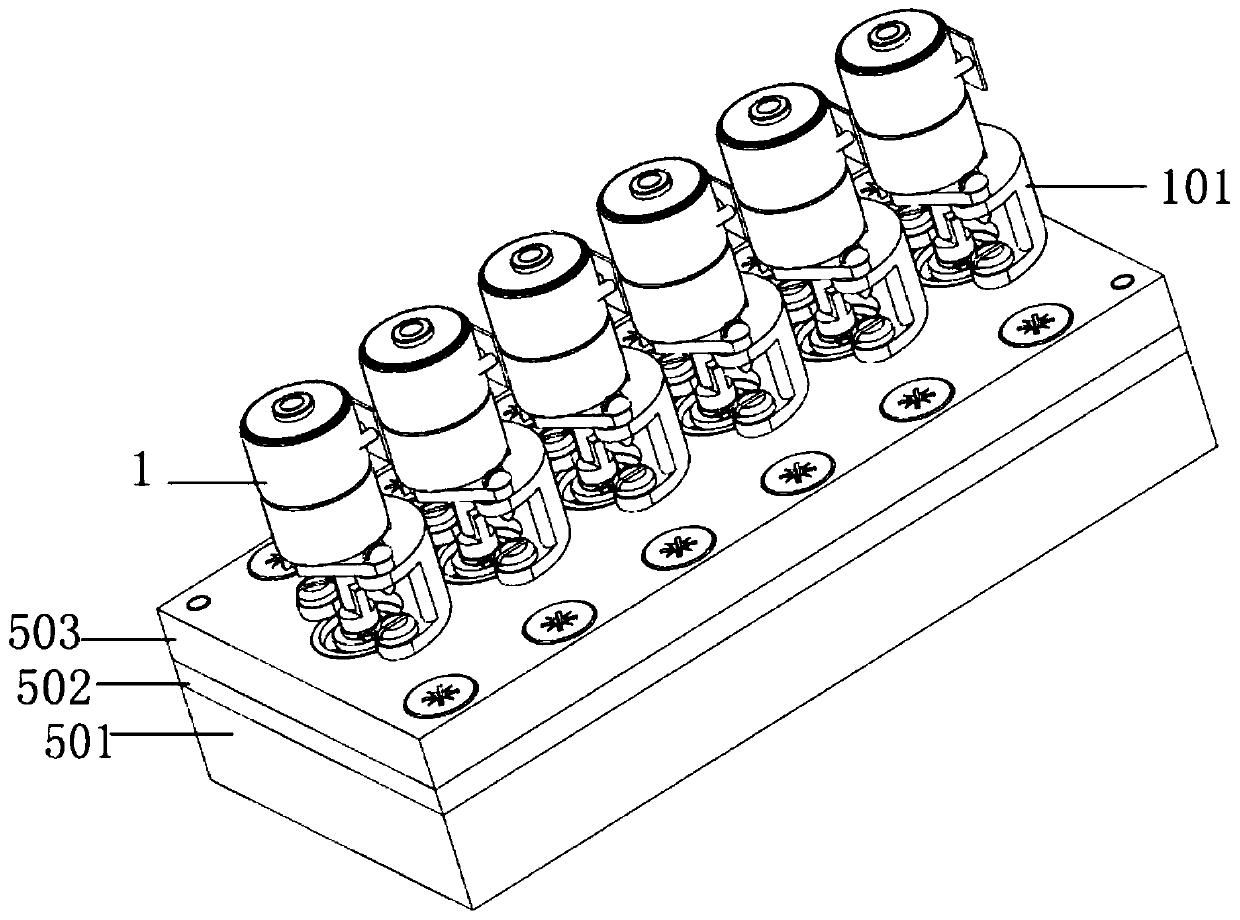

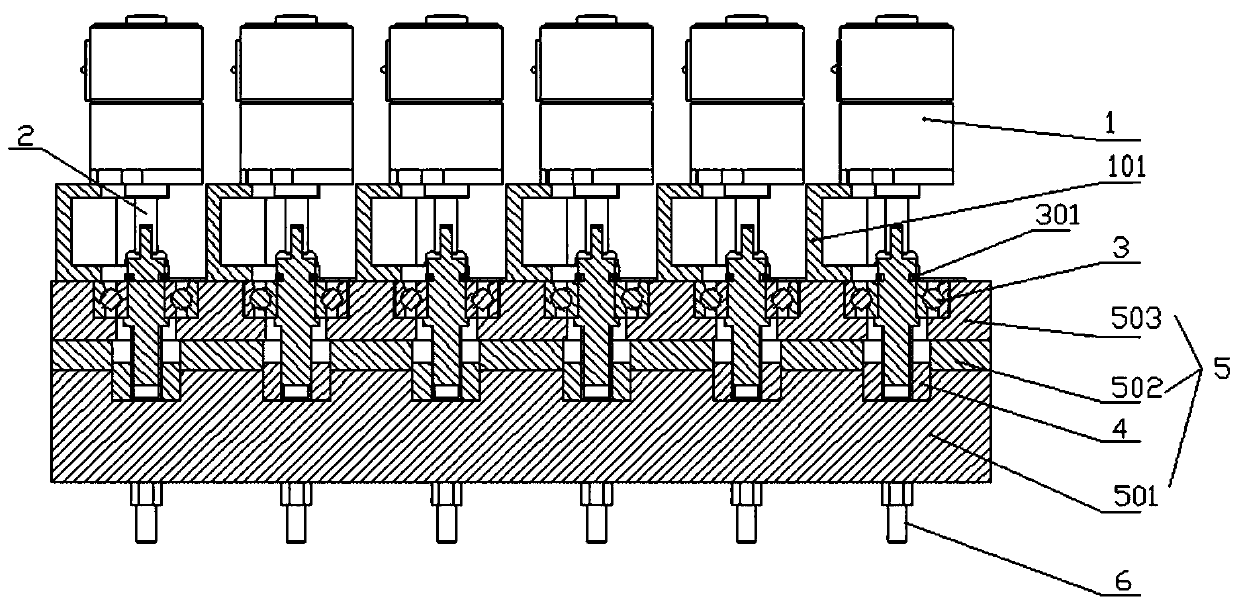

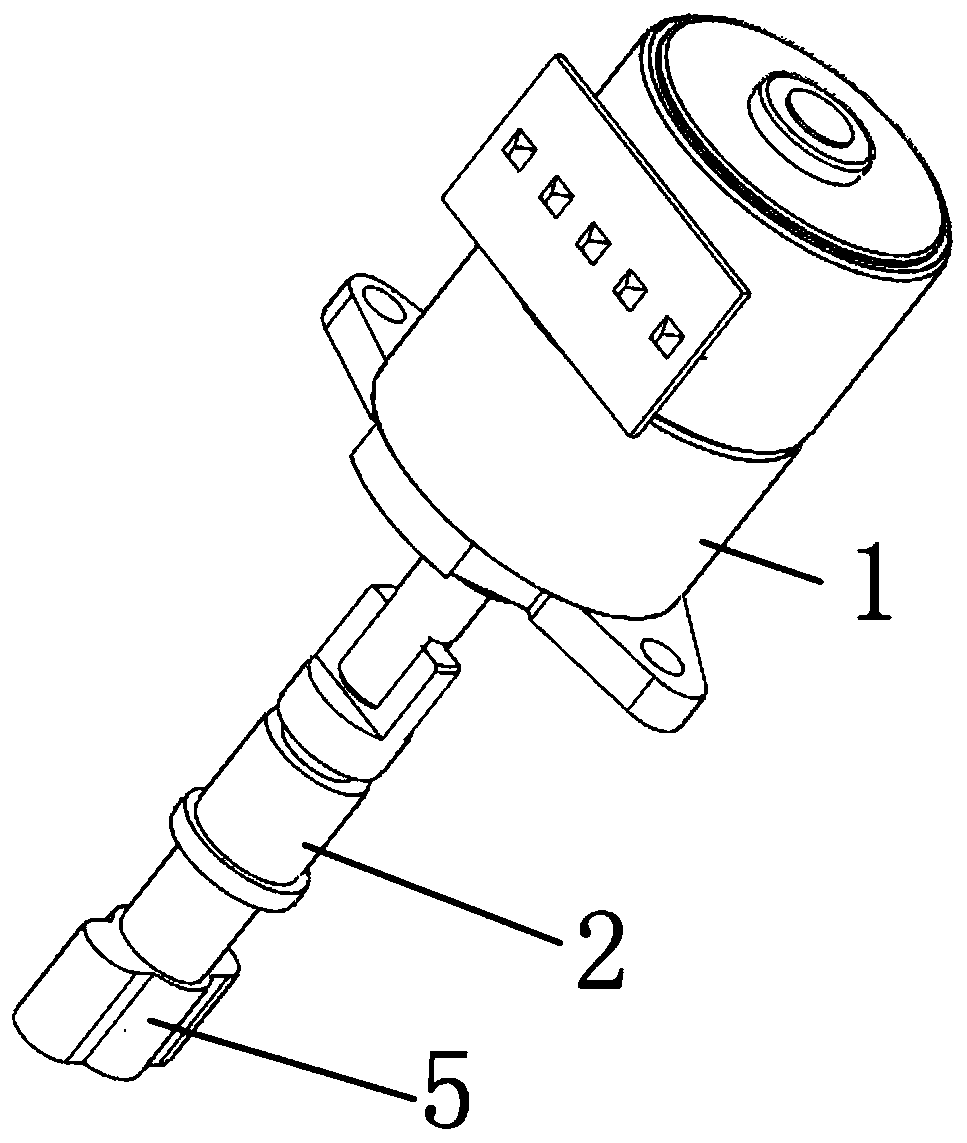

[0035] The manipulator is set as figure 2The two-finger structure shown. The control motor 1 is controlled by the program instruction, and can perform micro-distance single-step or continuous rotation, and drives the threaded shaft 2 to rotate. The shaft center of the threaded shaft 2 is connected to the valve 4 with a precision fine thread. Because the threaded shaft 2 and the bearing 3 that cannot move up and down Fixed connection, therefore, when the threaded shaft 2 rotates, it will drive the valve 4 to move up and down, so as to control the opening and closing of the valve 4, and achieve the purpose of controlling the flow rate of the liquid; at the same time, a clamp flow channel 5012 is set in the flow channel. The width of the flow channel is preferably set to 1mm. The liquid flow comes to the oil pipe through the nozzle-conduit-first oil connection port. When the liquid flow enters from the first oil port 803 and exits from the second oil port 804, the piston 801 is ...

Embodiment 2

[0037] The manipulator is provided with a three-finger structure. It can be set in the form of two fingers on one side and one finger on the other side, or three fingers distributed in a triangle. The control motor 1 is controlled by the program command and can perform macro single-step or continuous rotation, driving the threaded shaft 2 to rotate, and the threaded shaft 2. The shaft center is connected with the valve 4 with precision fine thread. Since the threaded shaft 2 is fixedly connected with the bearing 3 which cannot move up and down, when the threaded shaft 2 rotates, it will drive the valve 4 to move up and down, thereby controlling the opening and closing degree of the valve 4. To achieve the purpose of controlling the flow rate of the liquid flow; at the same time, a clamp flow channel 5012 is set in the flow channel, and the width of the flow channel at this place is preferably set to 0.8mm. When the liquid flow enters from the first oil port 803 and exits from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com