Non-energy-consumption instrument anti-freezing device

A technology without energy consumption and instrumentation, which is applied in the direction of heat preservation, pipes/pipe joints/fittings, heat exchange equipment, etc., can solve the problems of fluid condensation or solidification, and achieve the effects of convenient operation, simple structure, and accurate instrument measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

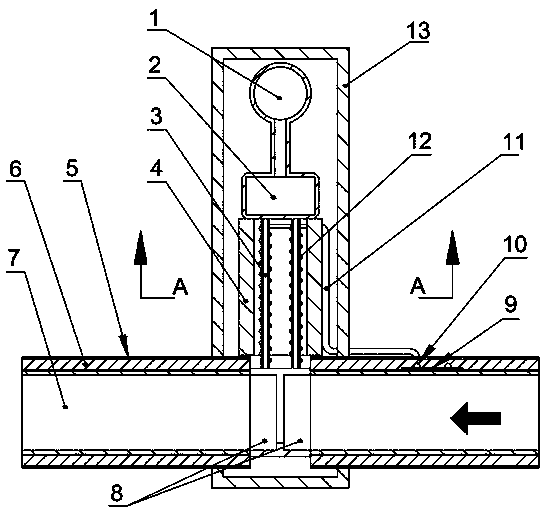

[0037] see Figure 1-3 As shown, there is no anti-freezing device for energy consumption instruments, including:

[0038] medium line 7,

[0039] The instrument body 2 has a cavity 8 and at least two drainage tubes 3 draining from the cavity 8, the cavity 8 communicates with the medium pipeline 7,

[0040] Wherein, the outer side of the medium pipeline 7 is covered with a heat-absorbing sleeve 9 , and the heat-absorbing sleeve 9 is connected to the drainage tube 3 through a heat-conducting element 11 . The medium pipeline 7 is made of metal material, such as iron, stainless steel, copper, gold, silver, etc. The present invention absorbs the heat of the flowing medium in the medium pipeline 7 through the heat-absorbing sleeve 9, and uses the heat conduction element 11 to transfer the heat to the existing freezing point. Condensation risk of drainage tube 3, so as to solve the problem of freezing risk of drainage tube 3 in low temperature environment, through this design, no n...

Embodiment 2

[0046] see Figure 1-3 As shown, there is no anti-freezing device for energy consumption instruments, including:

[0047] medium line 7,

[0048] The instrument body 2 has a cavity 8 and at least two drainage tubes 3 draining from the cavity 8, the cavity 8 communicates with the medium pipeline 7,

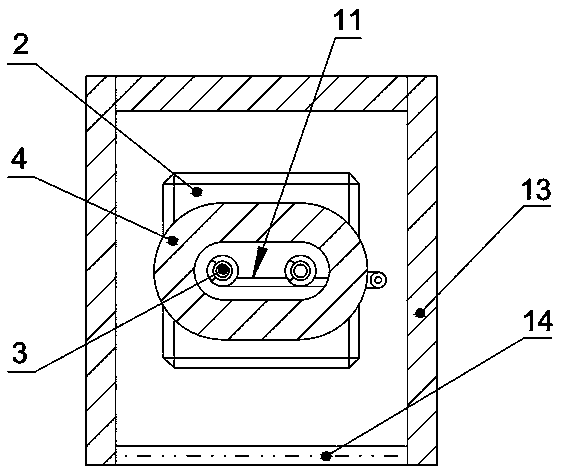

[0049] The insulation cover 4 is connected with the instrument main body 2 and the medium pipeline 7 to form a closed space for the drainage tube 3,

[0050] The heat preservation cover 13 is sealed and connected with the medium pipeline 7 to form a closed space for accommodating the instrument body 2 and the heat preservation cover 4. One side of the heat preservation cover 13 has a light-transmitting element 14,

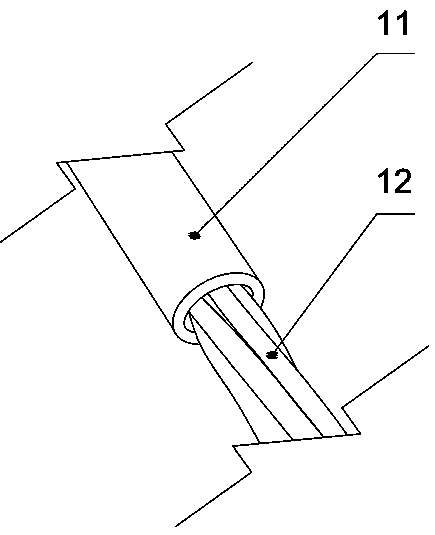

[0051] Among them, the outer side of the medium pipeline 7 is covered with a heat-absorbing sleeve 9, and the heat-absorbing sleeve 9 is connected to the drainage tube 3 through a heat-conducting element 11, and the heat-conducting element 11 passes through the heat p...

Embodiment 3

[0057] In this embodiment, on the basis of the technical solution in Embodiment 2, the non-energy consumption meter anti-freezing device is further improved, see Figure 4 As shown, a heat-conducting connecting piece 15 is connected between the heat-conducting wires 12 on the two drainage tubes 3, and the heat-conducting connecting piece 15 is a heat-conducting metal. The temperature of the medium fluid in the drainage tube 3 is close, which further ensures that the temperature of the medium fluid in the drainage tube 3 is consistent with the temperature of the medium in the medium pipeline 7, thereby improving data accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com