Injection valve for water injection system of internal combustion engine and water injection system having such injection valve

An injection valve and water injection technology, applied in fuel injection devices, internal combustion piston engines, charging systems, etc., can solve problems such as icing and damage of pipelines and/or components that guide water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

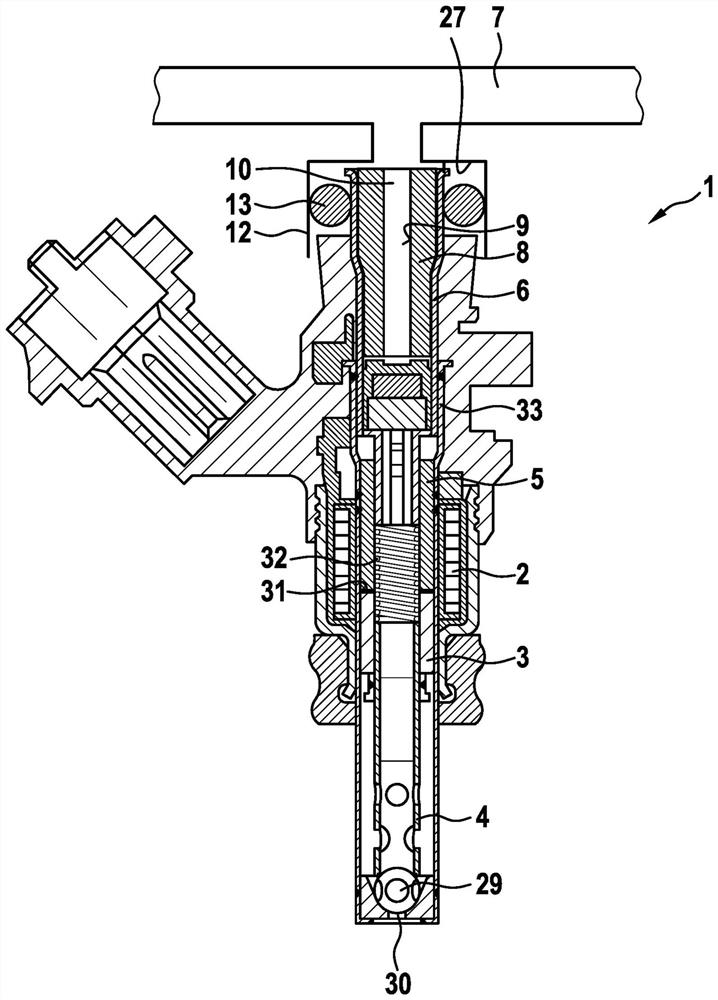

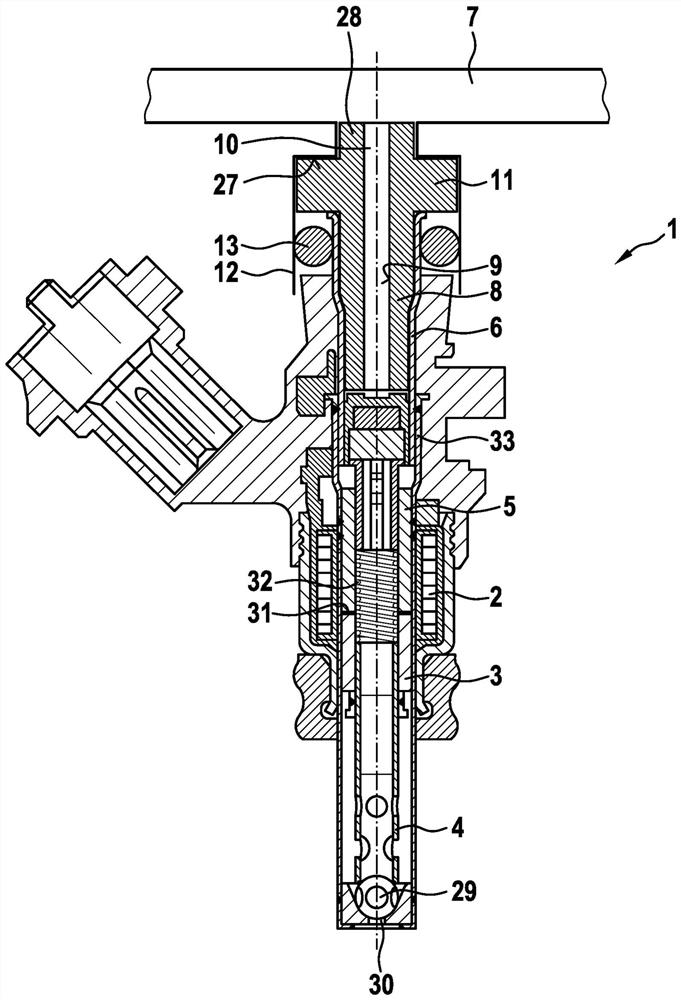

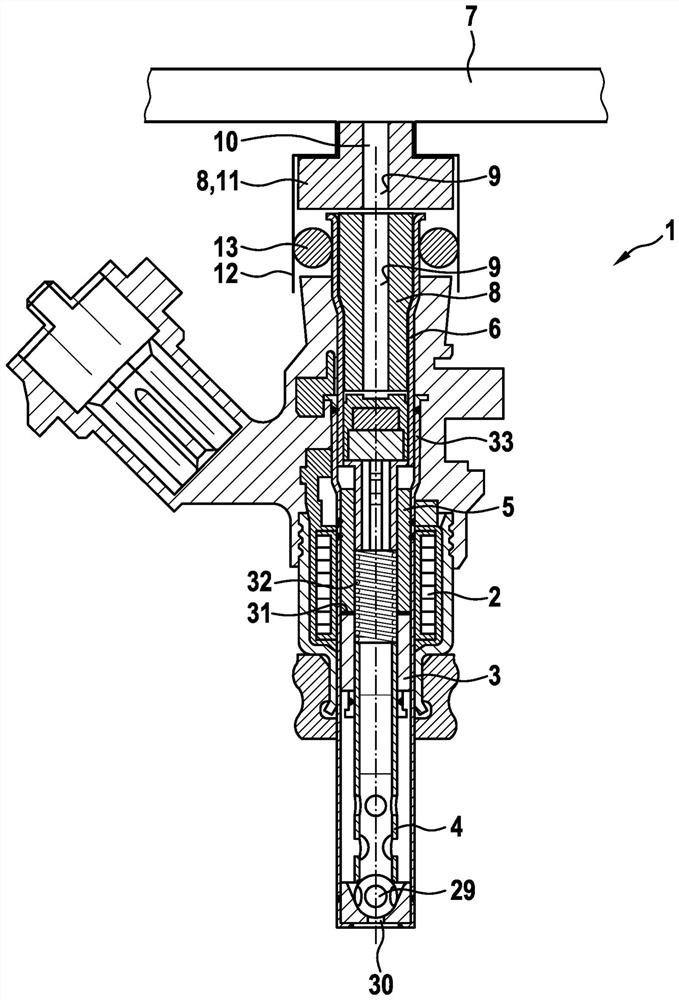

[0034] Depend on figure 1An injection valve 1 for a water injection system of an internal combustion engine is shown, which comprises an annular solenoid coil 1 for acting on a reciprocating armature 3 which is connected to a valve element 4 . The valve element 4 is now embodied as a hollow needle and is connected at its end facing away from the armature 3 to a spherical valve closing element 29 for releasing and closing the at least one injection opening 30 . When the solenoid coil 2 is energized, a magnetic field is formed whose magnetic force moves the armature 3 including the valve element 4 and the valve closing element 29 in the direction of the core 5 in order to close the working air gap 31 formed between the core 5 and the armature 3 . In this case, the spherical valve closing element 29 releases the injection opening 30 . If the energization of the solenoid coil 2 is then terminated, the armature 3 , the valve element 4 and the valve closing element 29 return to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com