Patents

Literature

127 results about "Water injection (engine)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

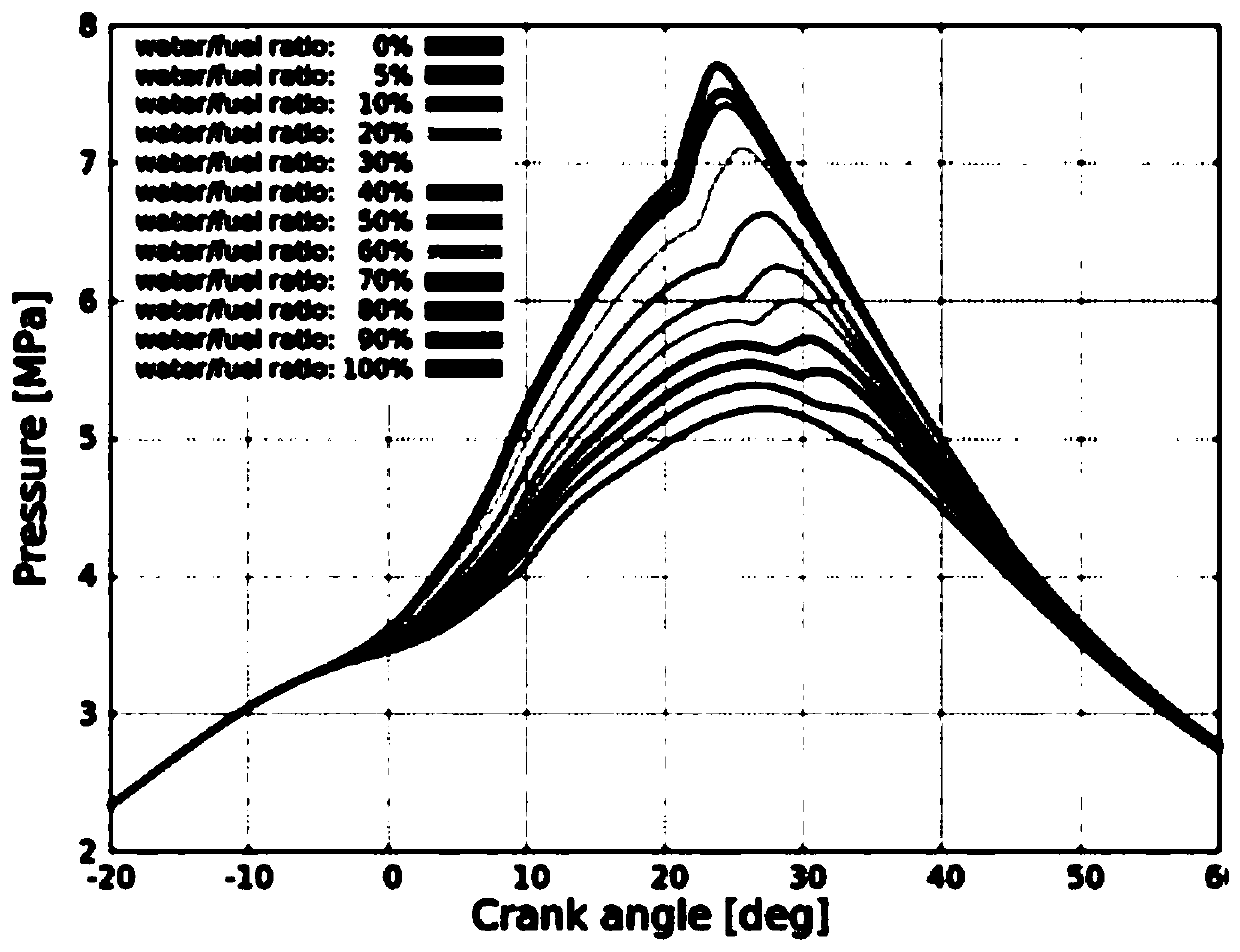

In internal combustion engines, water injection, also known as anti-detonant injection (ADI), can spray water into the incoming air or fuel-air mixture, or directly into the cylinder to cool certain parts of the induction system where "hot points" could produce premature ignition. In jet engines it increases engine thrust at low speeds and at takeoff.

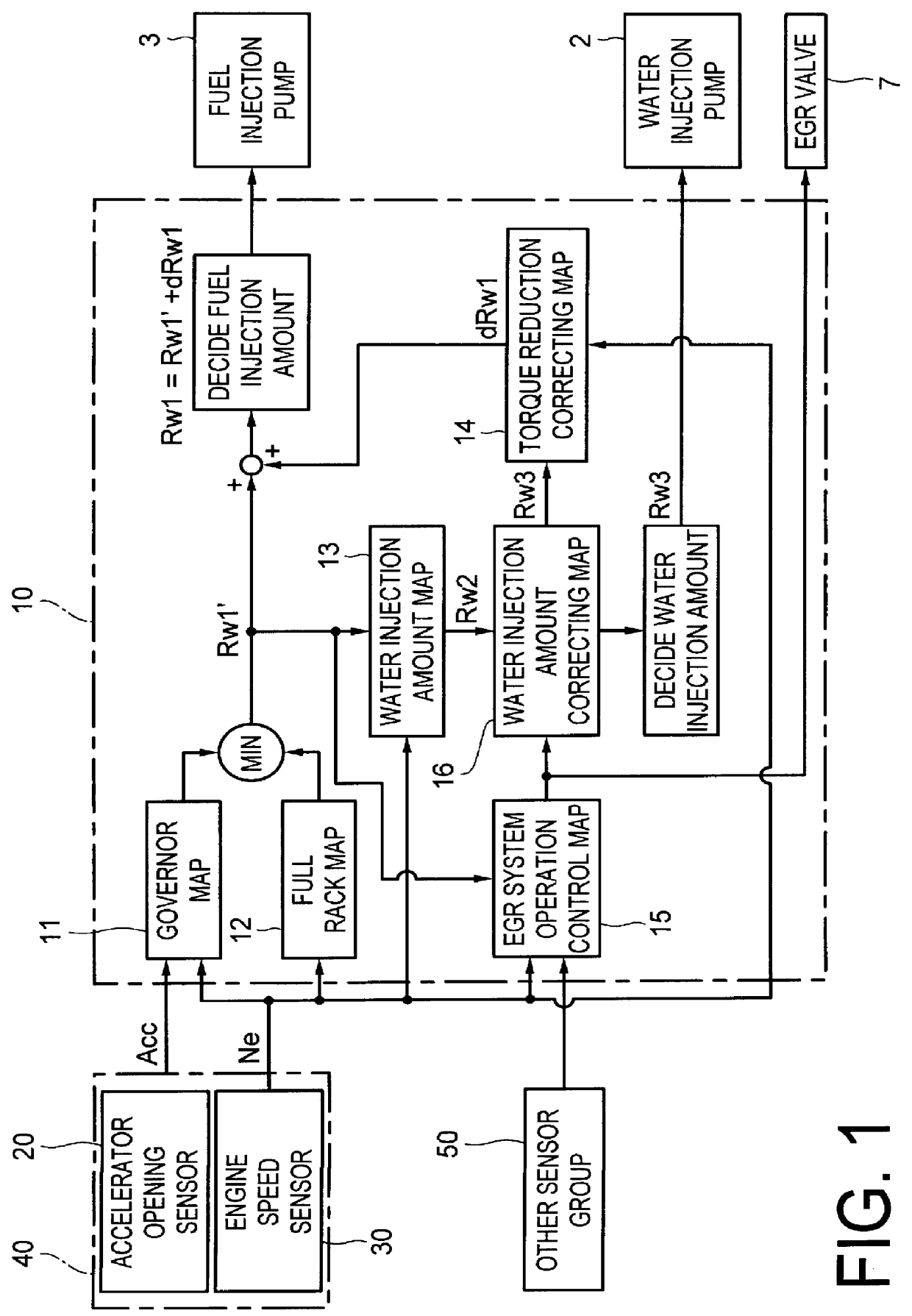

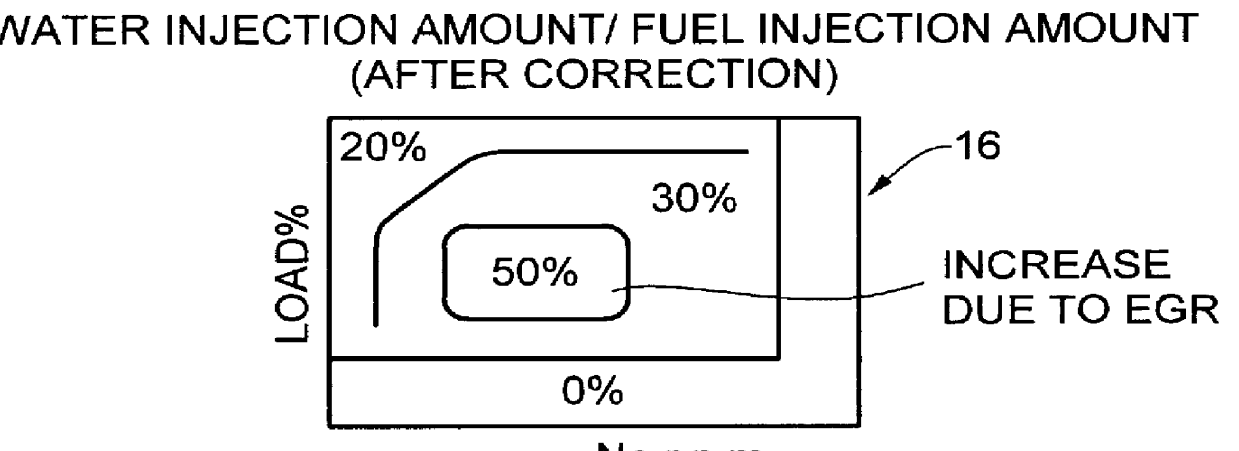

Water injection amount control system for fuel and water injection engine

InactiveUS6112705AEnhance NOx reducing effectImprove reducibilityElectrical controlNon-fuel substance addition to fuelCombustion chamberControl system

A water injection amount control system for a fuel and water injection engine, comprises running state detecting unit for detecting the running state of the engine; an EGR system for recirculating part of exhaust gas of the engine to a combustion chamber of the engine; EGR system operating state detecting unit for detecting or estimating the operating state of the EGR system; water injection amount regulating unit for regulating an amount of water to be injected to the combustion chamber of the engine; and control unit for controlling the operation of the water injection amount regulating unit: wherein the system is arranged to have water injection amount setting unit for deciding a water injection amount based on information from the running state detecting unit and on the operating state of the EGR system detected by the EGR system operating state detecting unit, so that the control unit controls the operation of the water injection amount regulating unit based on the water injection amount decided by the water injection amount setting unit.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

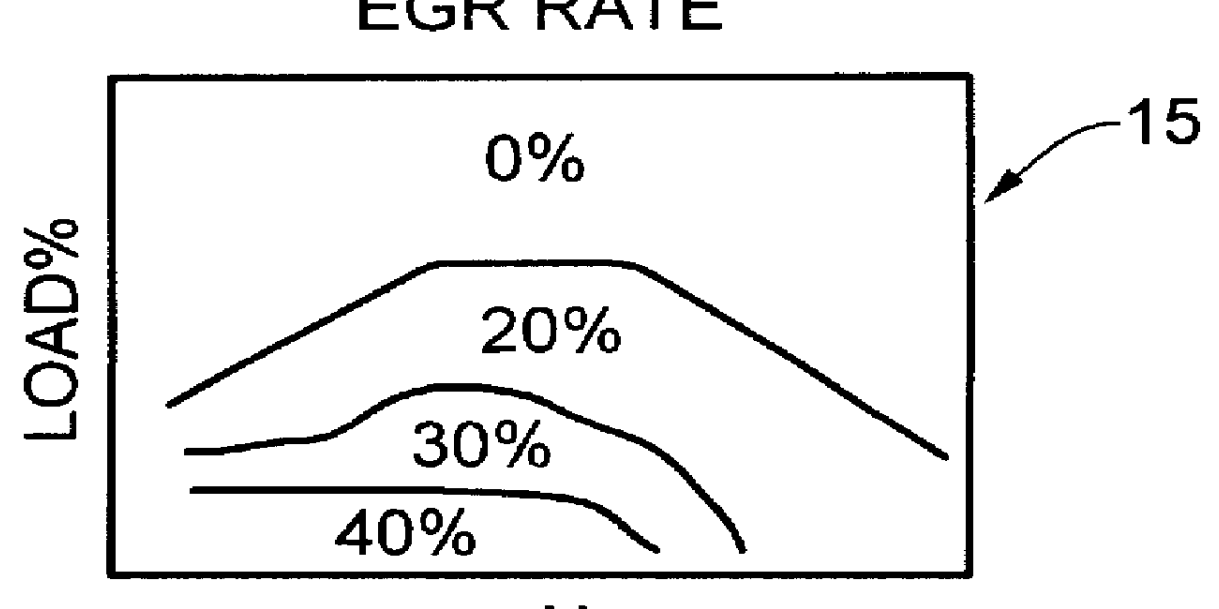

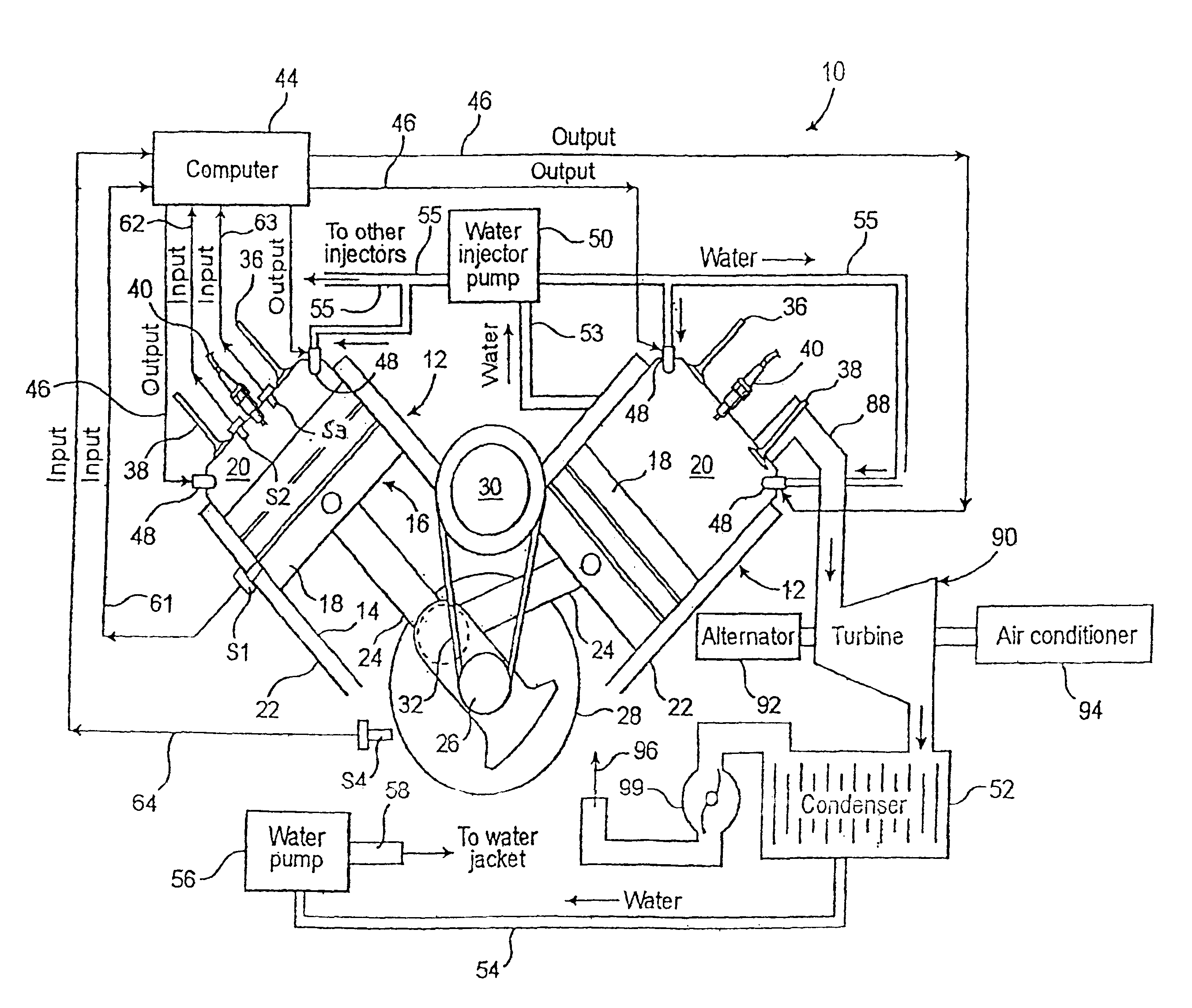

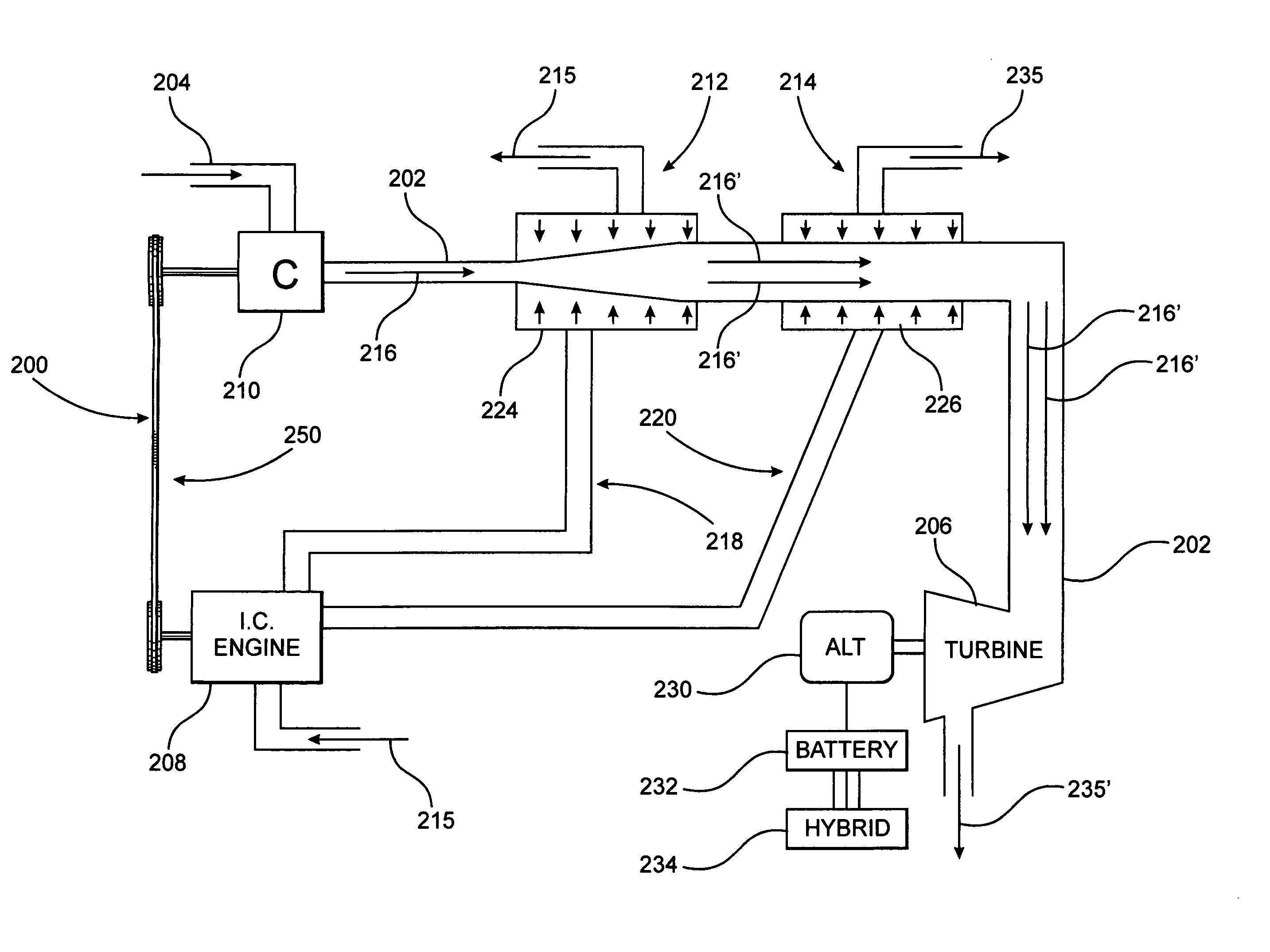

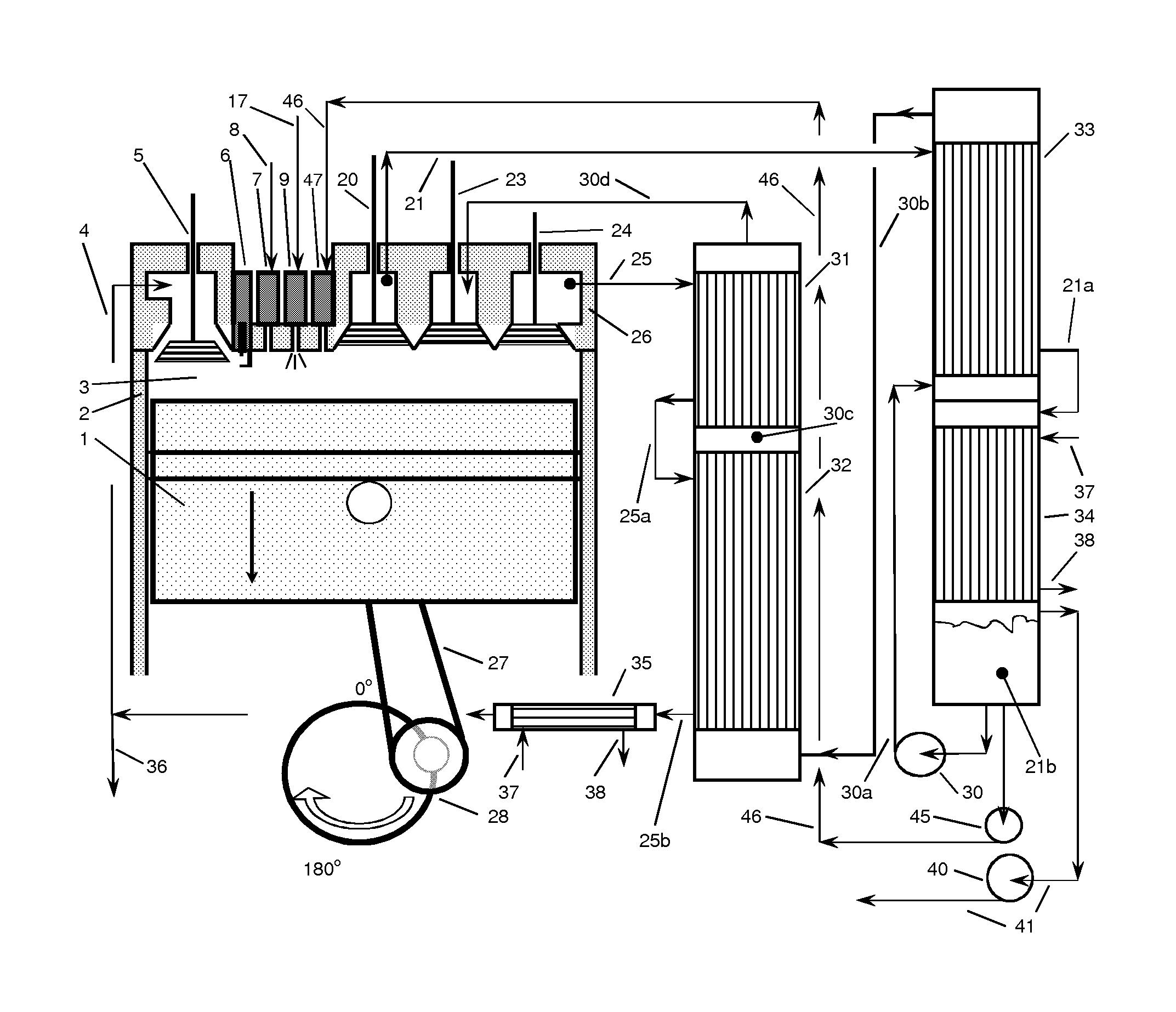

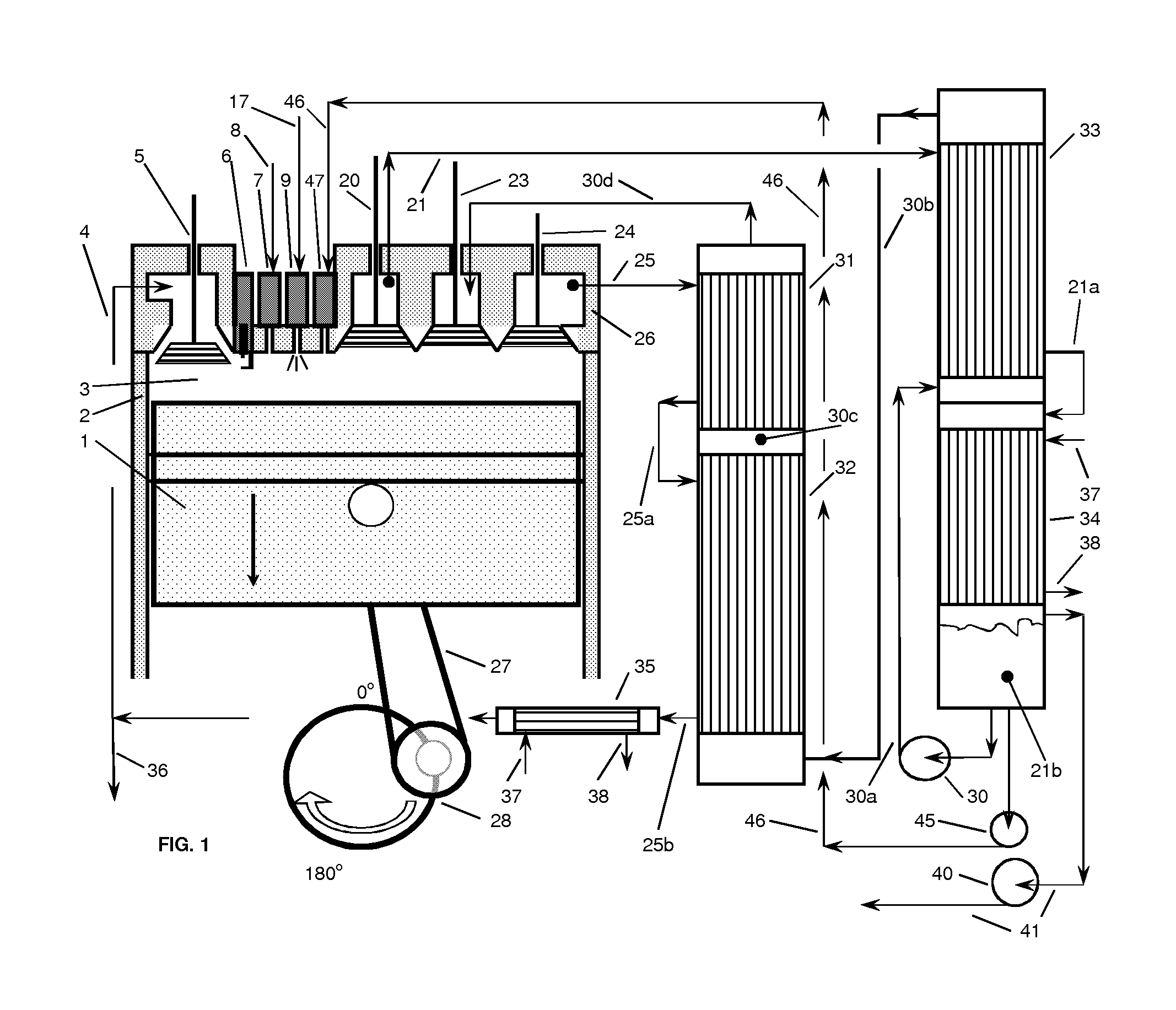

System and method for recovering wasted energy from an internal combustion engine

InactiveUS20060124079A1Efficient powerReduce compressionNon-fuel substance addition to fuelInternal combustion piston enginesExhaust fumesRisk stroke

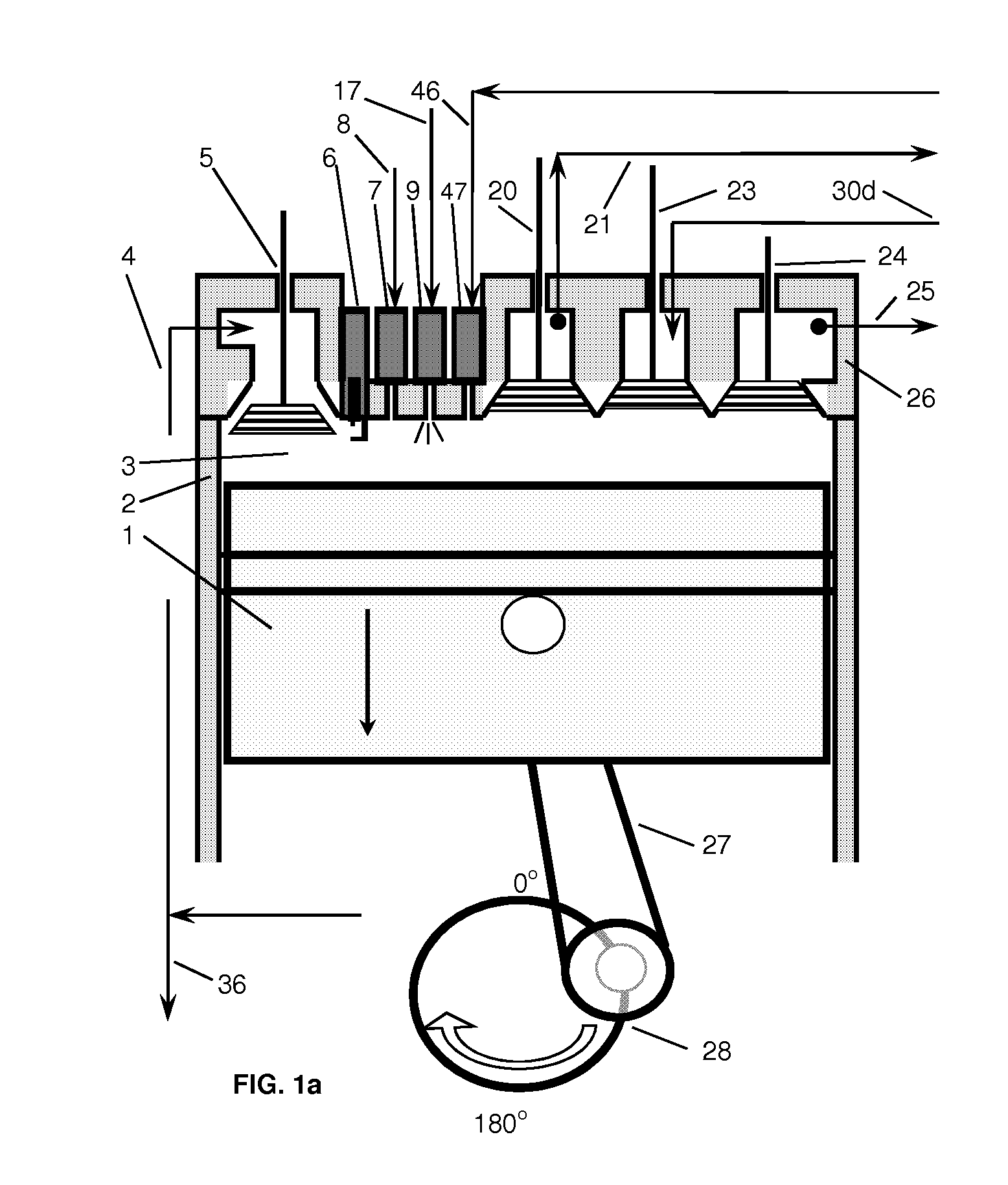

An internal combustion engine and its method of operation including at least one embodiment operating on a six-stroke cycle and including at least one piston and cylinder assembly. The six-stroke cycle includes two power strokes, the latter of which is the result of a water to steam conversion process utilizing the heat of the exhaust gas from the first power stroke. A second embodiment comprises a hybrid power generating assembly incorporating alternative, first and second power sources respectively comprising an internal combustion engine and a water injection engine, the latter of which operates on the water to steam conversion process, wherein the required heat therefore is derived from the exhaust gas of the internal combustion engine. Another preferred embodiment comprises the utilization of different normally wasted heat sources from an IC engine for the generation of sufficient work energy to drive a power take-off, such as hybrid drive assembly.

Owner:SINGH SATNARINE

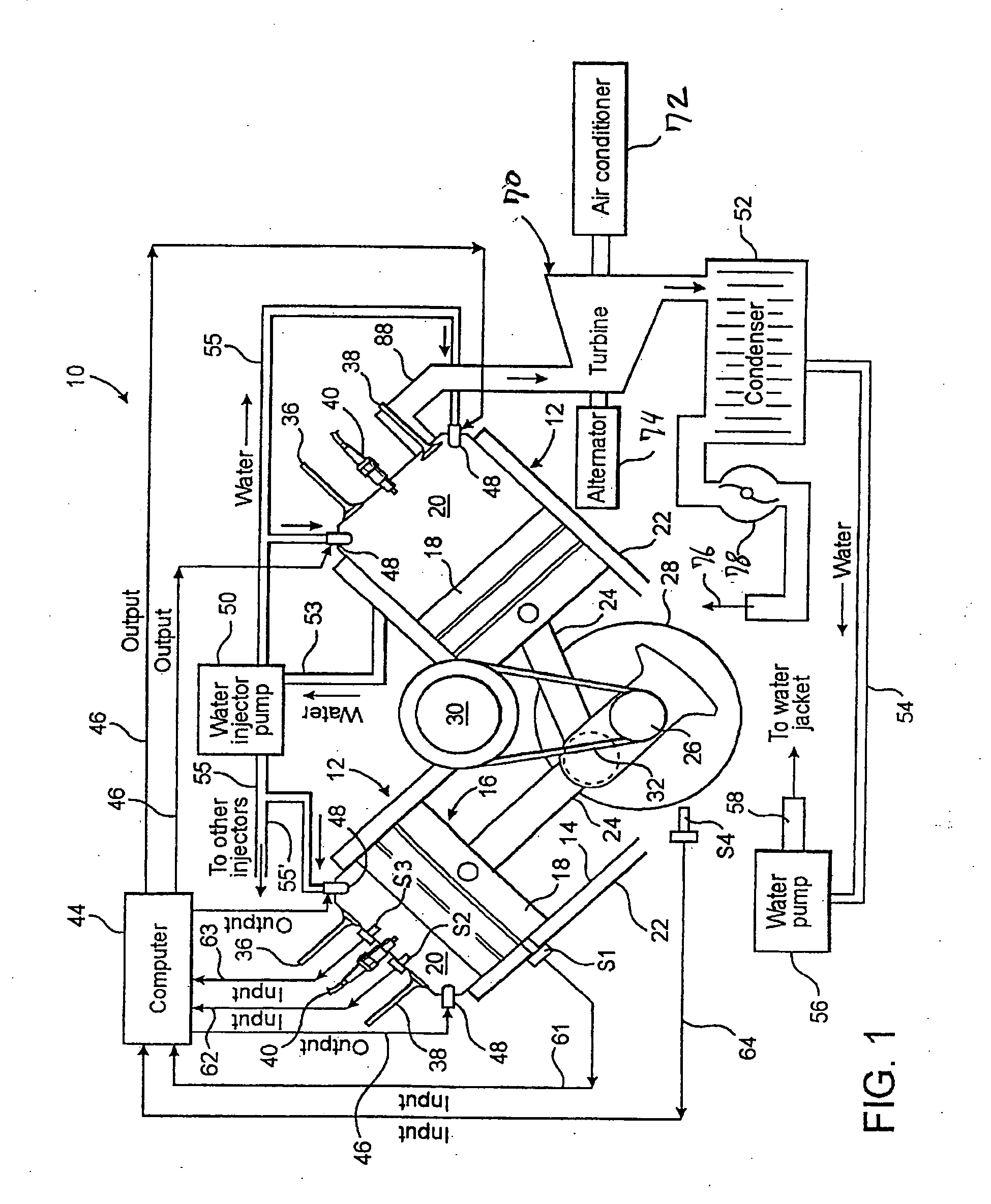

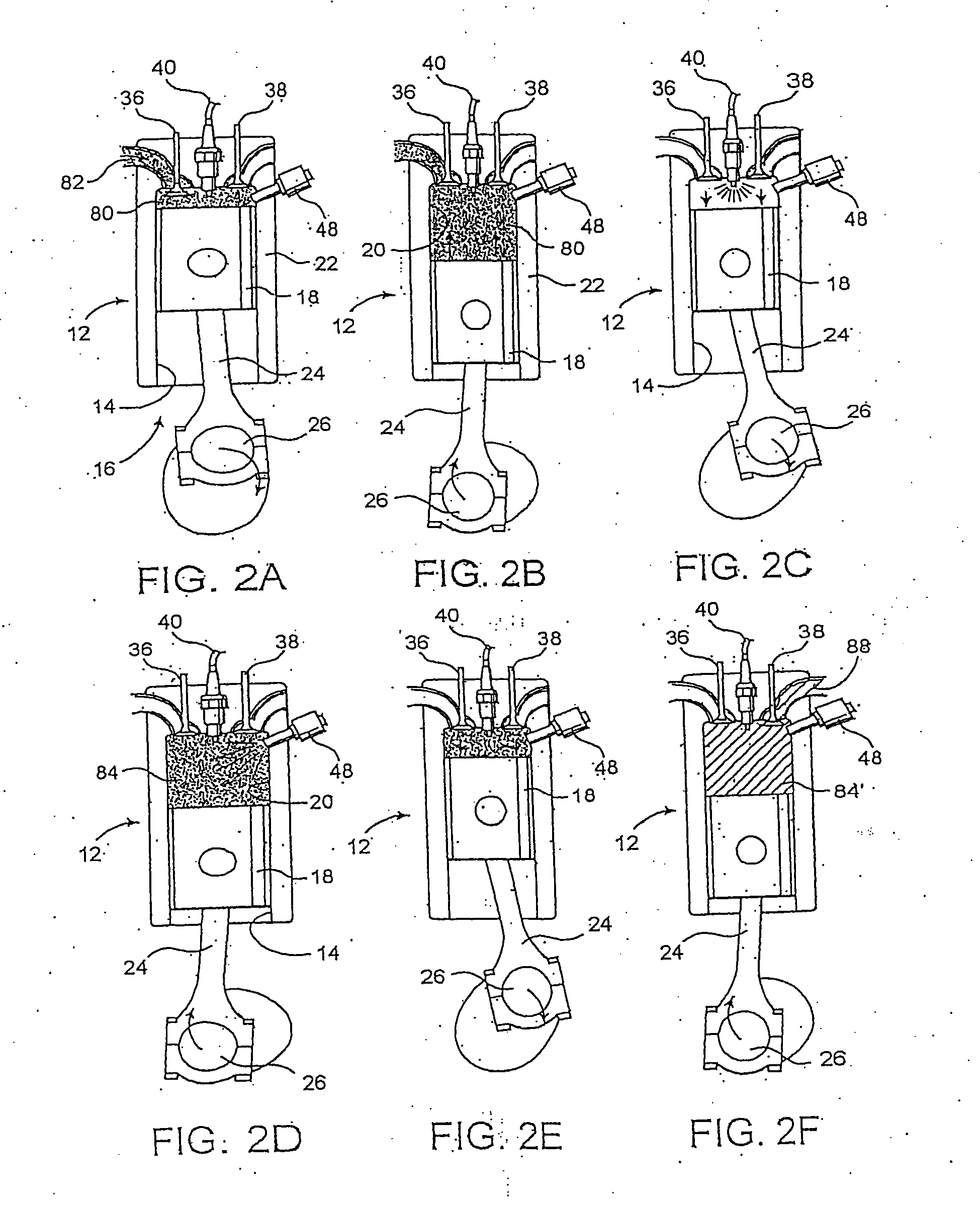

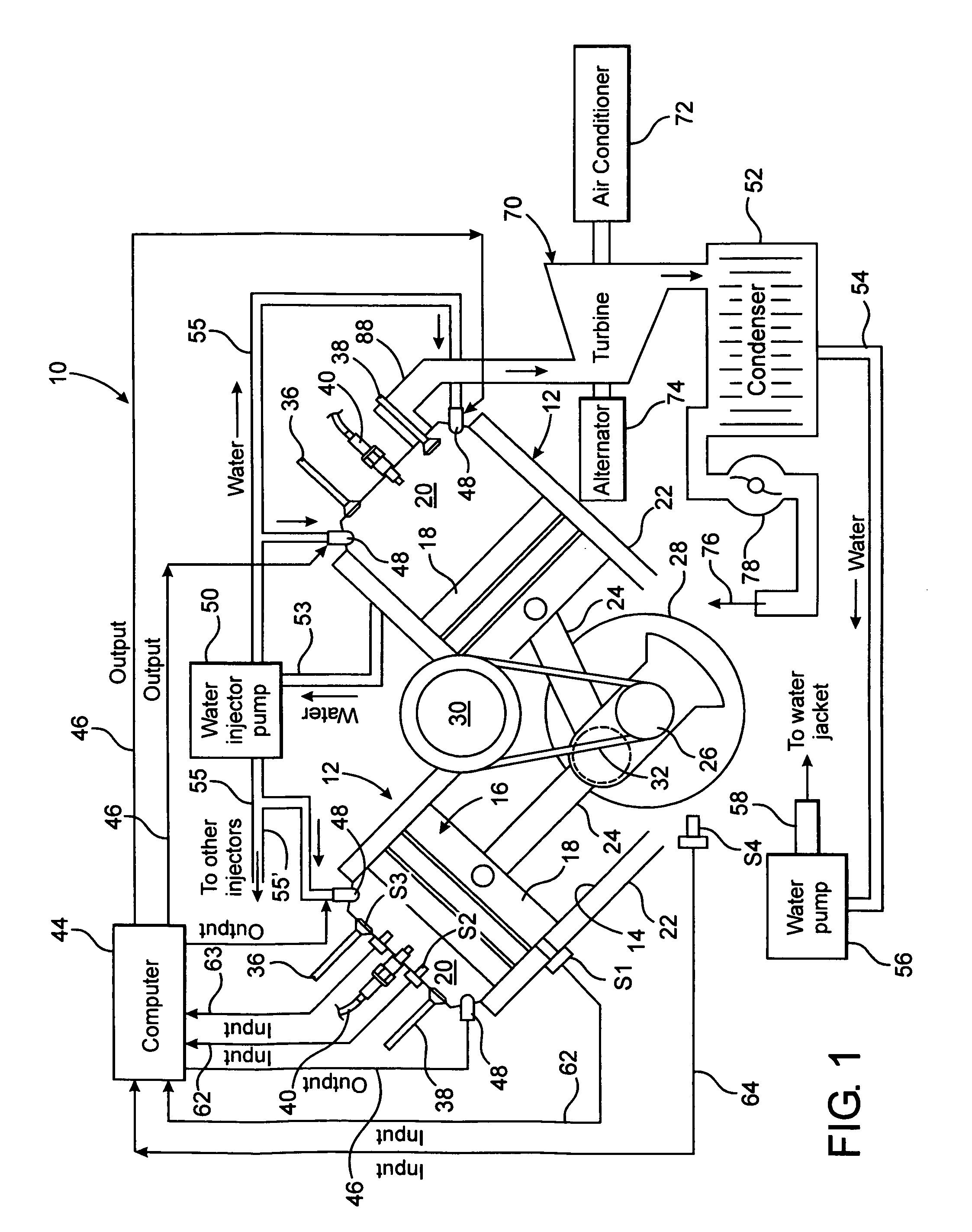

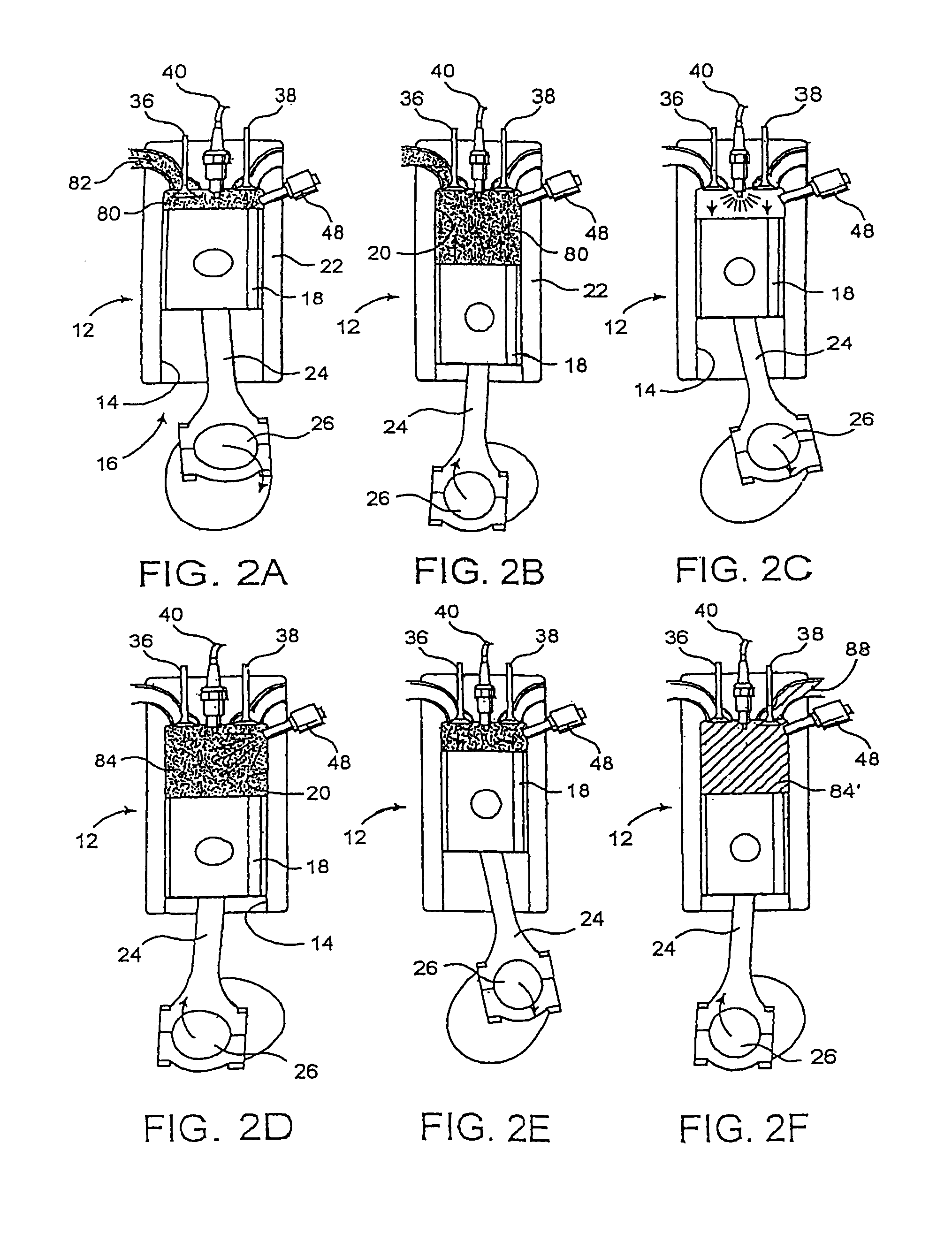

Computer controlled multi-stroke cycle power generating assembly and method of operation

InactiveUS7021272B2Reciprocating combination enginesInternal combustion piston enginesInternal combustion enginePower take-off

An internal combustion engine and its method of operation including at least one embodiment operating on a six-stroke cycle and including at least one piston and cylinder assembly. The six-stroke cycle includes two power strokes, the latter of which is the result of a water to steam conversion process utilizing the heat of the exhaust gas from the first power stroke. A second embodiment comprises a hybrid power generating assembly incorporating alternative, first and second power sources respectively comprising an internal combustion engine and a water injection engine, the latter of which operates on the water to steam conversion process, wherein the required heat therefore is derived from the exhaust gas of the internal combustion engine. The second power source drives a source of electric energy which powers an electric motor, wherein the electric motor and the internal combustion engine are both connected in driving relation to a power take-off.

Owner:SINGH SATNARINE

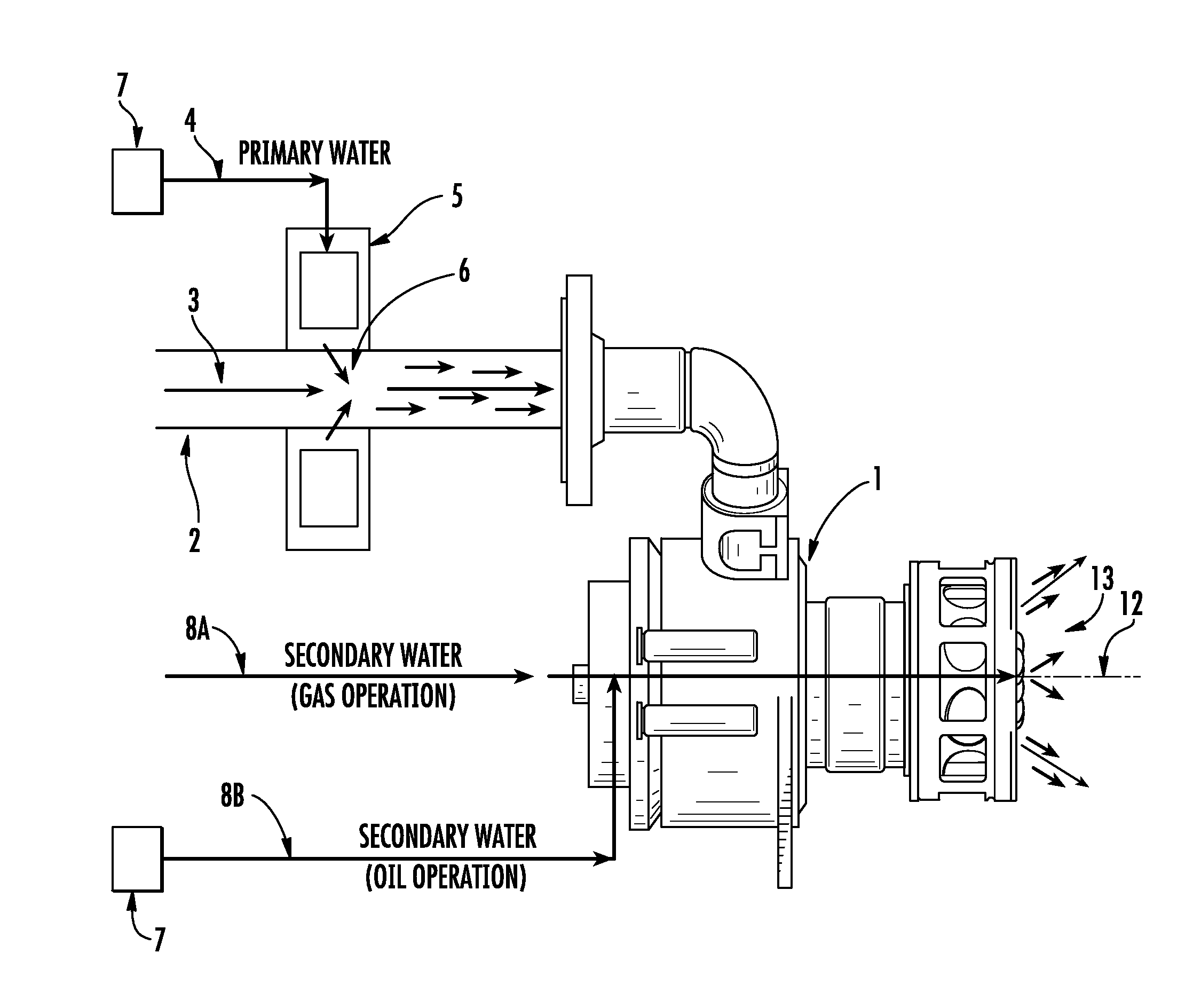

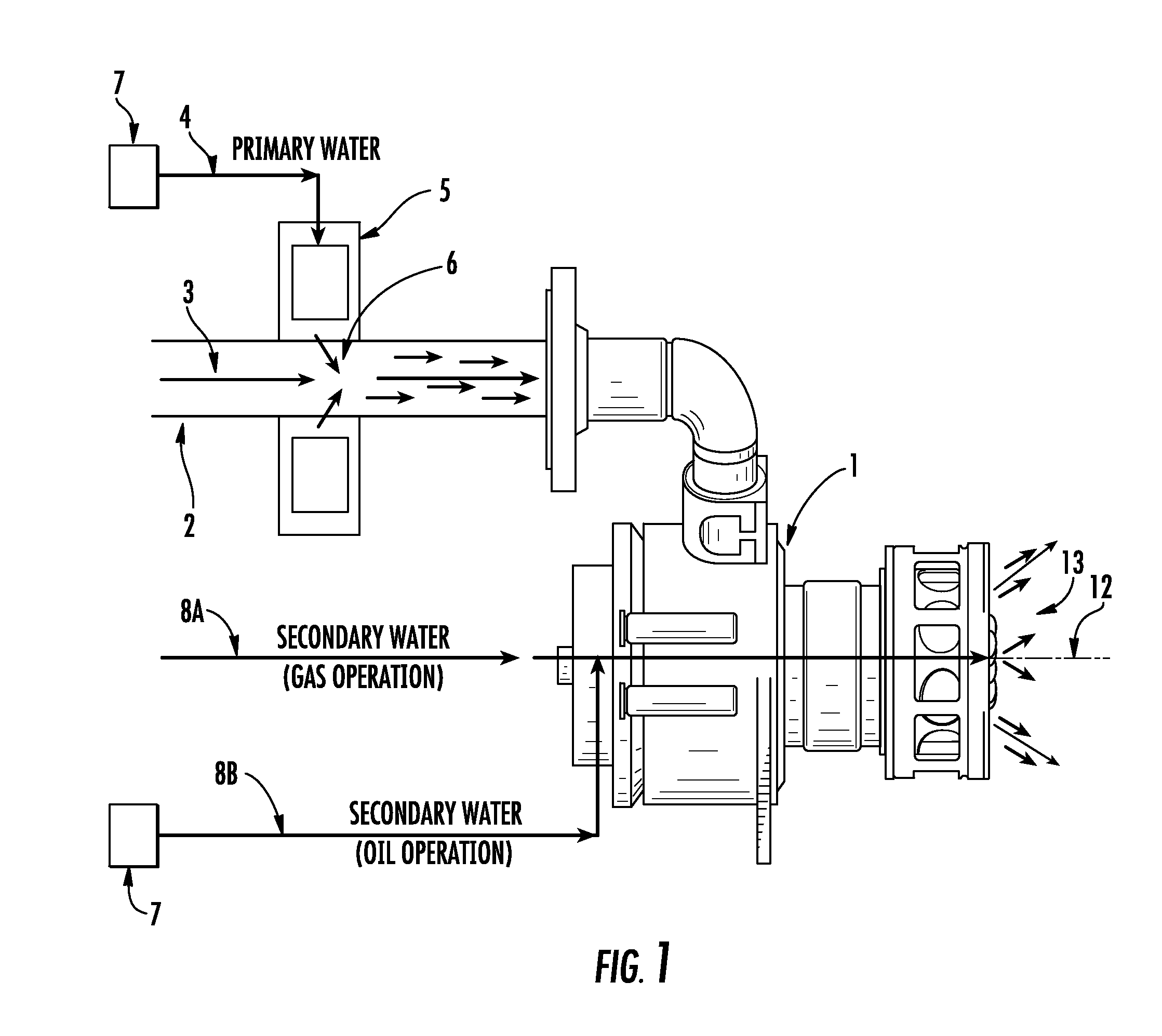

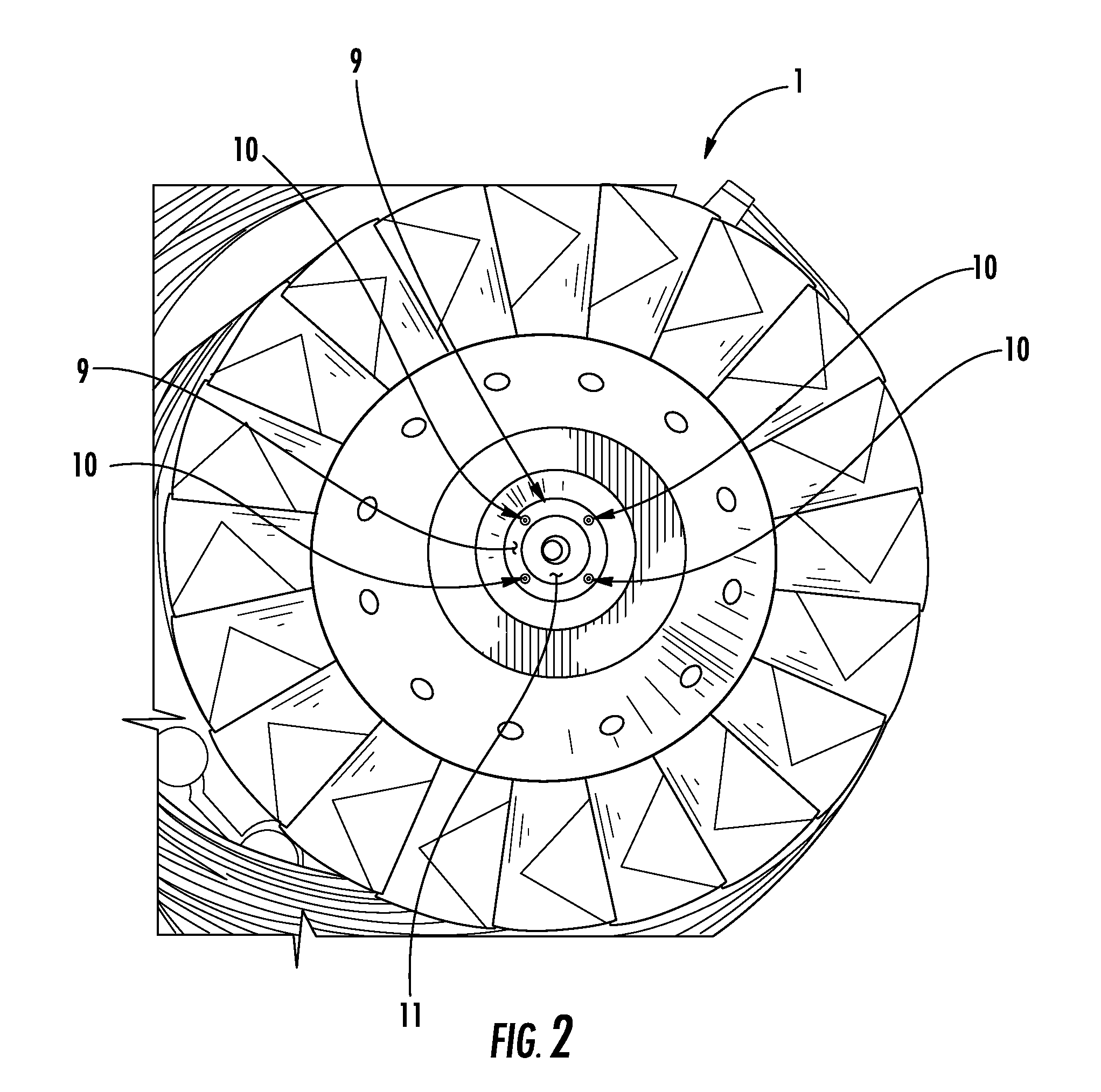

Secondary water injection for diffusion combustion systems

InactiveUS20110314831A1Easy to controlReduce wearTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemEngineering

Owner:SIEMENS ENERGY INC

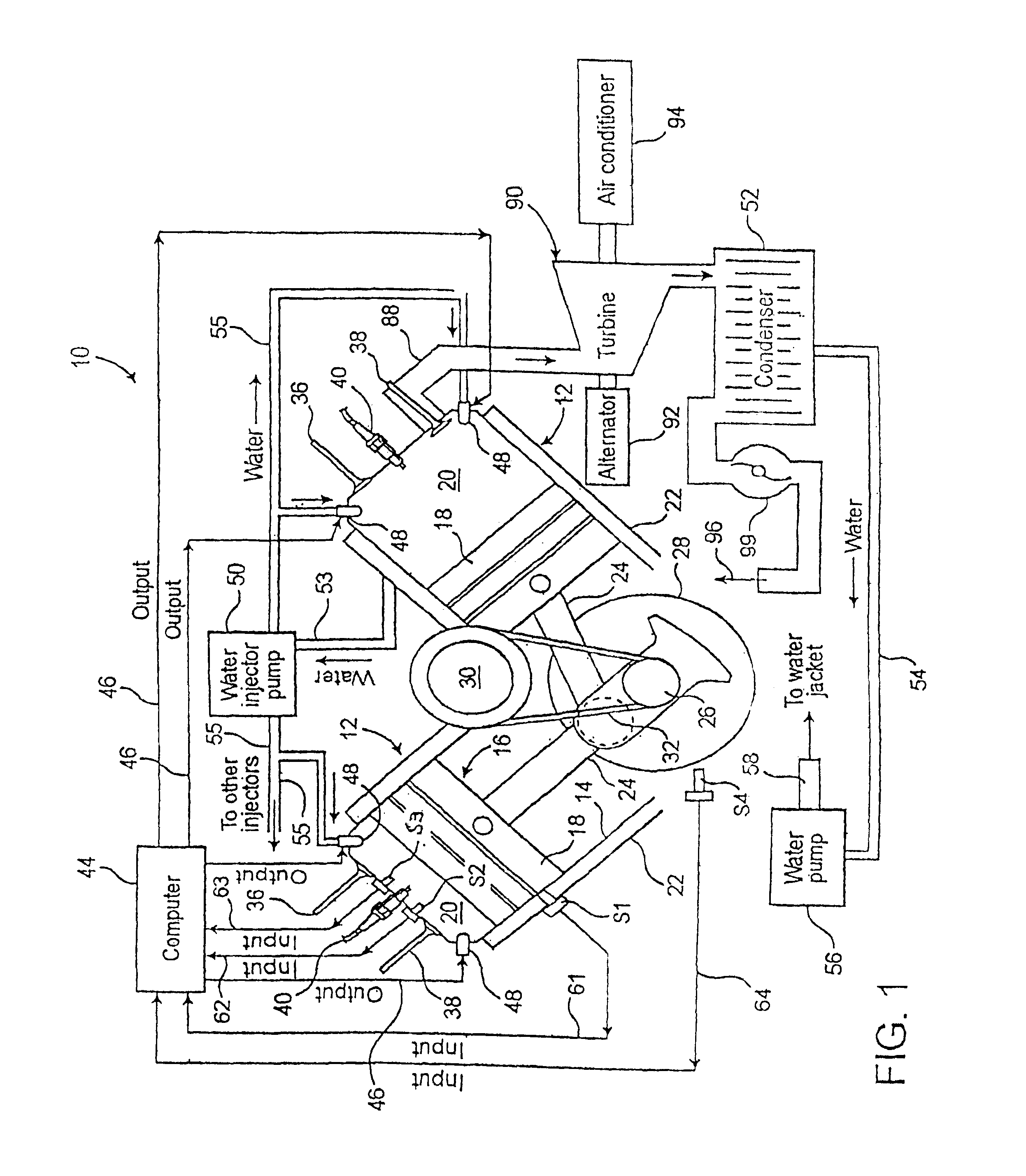

System and method for recovering wasted energy from an internal combustion engine

InactiveUS7549412B2Efficient powerReduce compressionNon-fuel substance addition to fuelInternal combustion piston enginesExternal combustion engineExhaust fumes

An internal combustion engine and its method of operation including at least one embodiment operating on a six-stroke cycle and including at least one piston and cylinder assembly. The six-stroke cycle includes two power strokes, the latter of which is the result of a water to steam conversion process utilizing the heat of the exhaust gas from the first power stroke. A second embodiment comprises a hybrid power generating assembly incorporating alternative, first and second power sources respectively comprising an internal combustion engine and a water injection engine, the latter of which operates on the water to steam conversion process, wherein the required heat therefore is derived from the exhaust gas of the internal combustion engine. Another preferred embodiment comprises the utilization of different normally wasted heat sources from an IC engine for the generation of sufficient work energy to drive a power take-off, such as hybrid drive assembly.

Owner:SINGH SATNARINE

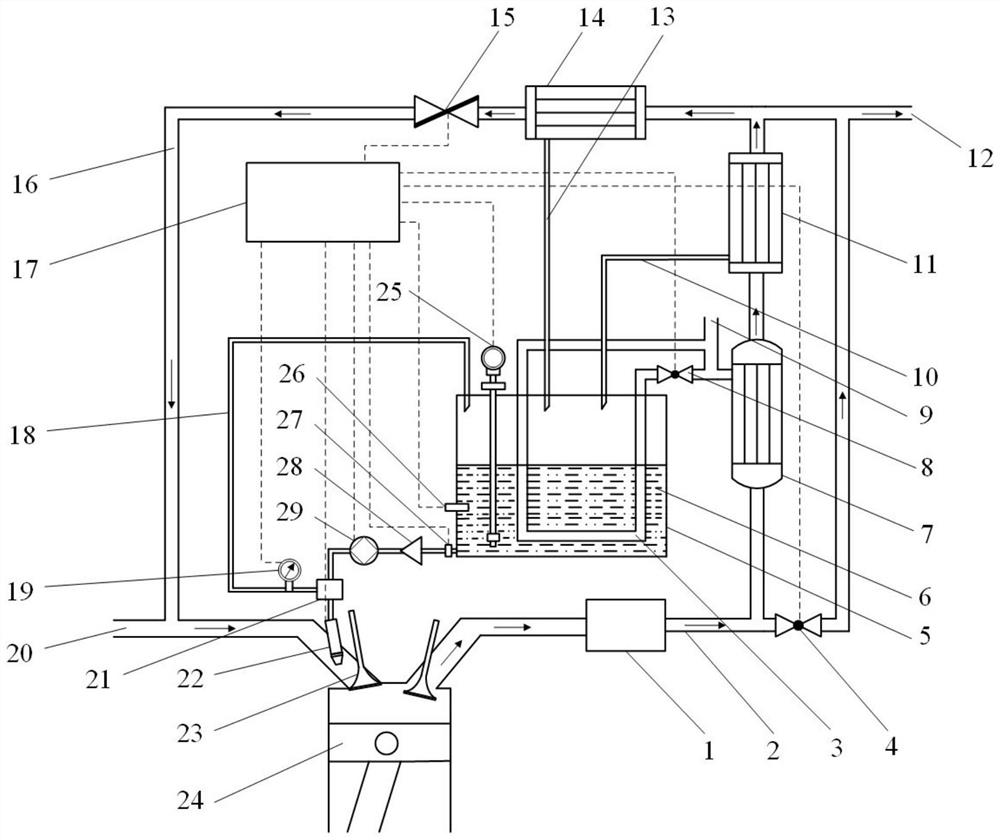

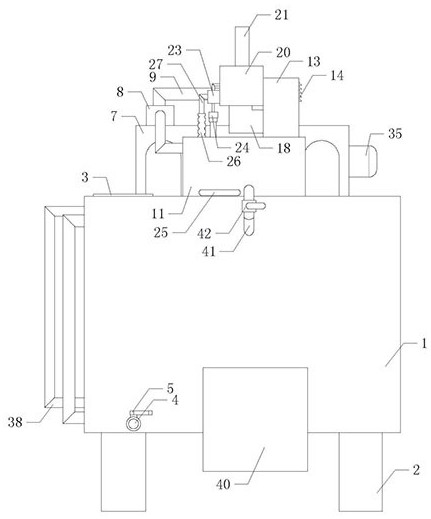

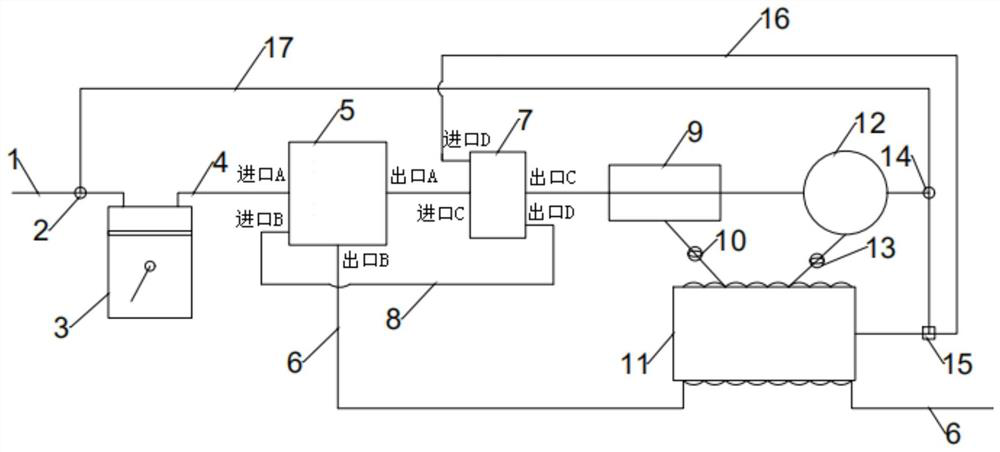

System for recycling water in engine waste gas and then injecting water into inlet gas

ActiveCN113266494AImprove sustainabilityImprove recycling ratesInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberWater vapor condensation

The invention relates to a system for recycling water in engine waste gas and then injecting the water into inlet gas. The system comprises a heat exchanger, a cooling liquid outlet bypass valve, a cooling liquid outlet bypass pipeline, a first water vapor condensation separator, a second water vapor condensation separator, a recycling water tank, a water spraying assembly (water injector), an exhaust aftertreatment device, an exhaust bypass valve, a terminal exhaust pipe, an EGR valve, an EGR pipeline and an electronic control unit (ECU). Moisture in the waste gas is recycled and removed, and then the recycled condensate water is sprayed into a gas inlet channel through a water injector and enters an engine combustion chamber after being mixed with fresh charge, so that the combustion temperature in a cylinder is reduced, and the risk of NOx emission and abnormal combustion is effectively reduced; and meanwhile, the sustainability and the running mileage of the air inlet water injection function of an engine are greatly improved, the cyclic utilization rate of water is increased, condensed accumulated water in an EGR system is reduced, the control precision and the stability of the EGR system are improved, and the service life of the EGR system is prolonged.

Owner:DALIAN UNIV OF TECH

Industrial steel strip performance testing device

InactiveCN103411842AEasy to assembleEasy to operateWeather/light/corrosion resistanceStrength propertiesData displayMoisture sensor

The invention relates to an industrial steel strip performance testing device. A storage battery, a winding engine and an auxiliary support frame are arranged inside a power warehouse; a testing frame is arranged at the upper part of the power warehouse; heating wires are distributed at the raised parts at the two edges of the testing frame; a to-be-tested steel strip is fixed at the middle part of the testing frame; a pressure sensor is arranged between the steel strip and the testing frame; a steel rope is connected onto the winding engine; the steel rope penetrates upwards through the testing frame and is connected with a weight after bypassing a guide pulley and a fixed pulley; water injection nozzles are arranged at the upper part of a closed laboratory; an observation window is arranged on a side surface of the closed laboratory; a temperature sensor and a humidity sensor are arranged on the inner wall of the closed laboratory; a data display instrument, and a speed controller which can control the speed of the winding engine are arranged on the outer wall of a housing. The testing device is simple in assembly and easy to operate, and can simulate multiple complex environments, and enable the performance test of steel strips before the steel strips are put into industrial production normally to be practicable, and is suitable for popularization and application in the field of steel strip test.

Owner:刘烨

High Thermal Efficiency Six Stroke Internal Combustion Engine with Heat Recovery and Water Injection

InactiveUS20160369750A1Capture engine noiseQuiet engineInternal combustion piston enginesNon-fuel substance addition to fuelParticulatesEngineering

A six stroke high thermal efficiency engine and a method for operating such an engine are disclosed. Oxygen or oxygen-enriched air is used as the oxidizer, water may or may not be used to mitigate and control the temperature of combustion, heat is recovered from the two exhaust strokes, superheated steam is used in the second power stroke, and high levels of exhaust gas from stroke four are recirculated. Lean burn combustion is utilized to produce an oxygen rich exhaust which results in very low levels of particulates, unburned hydrocarbons, and carbon monoxide. Due to high thermal efficiency, carbon dioxide emissions are reduced per unit of power output. Use of oxygen or oxygen-enriched air as the oxidizer produces an exhaust containing very low levels of nitrogen oxides. The engine is insulated to conserve heat, resulting in reduced engine noise. An engine with high thermal efficiency, quiet operation, and low emissions is the result.

Owner:JUNG PHILIP OWEN

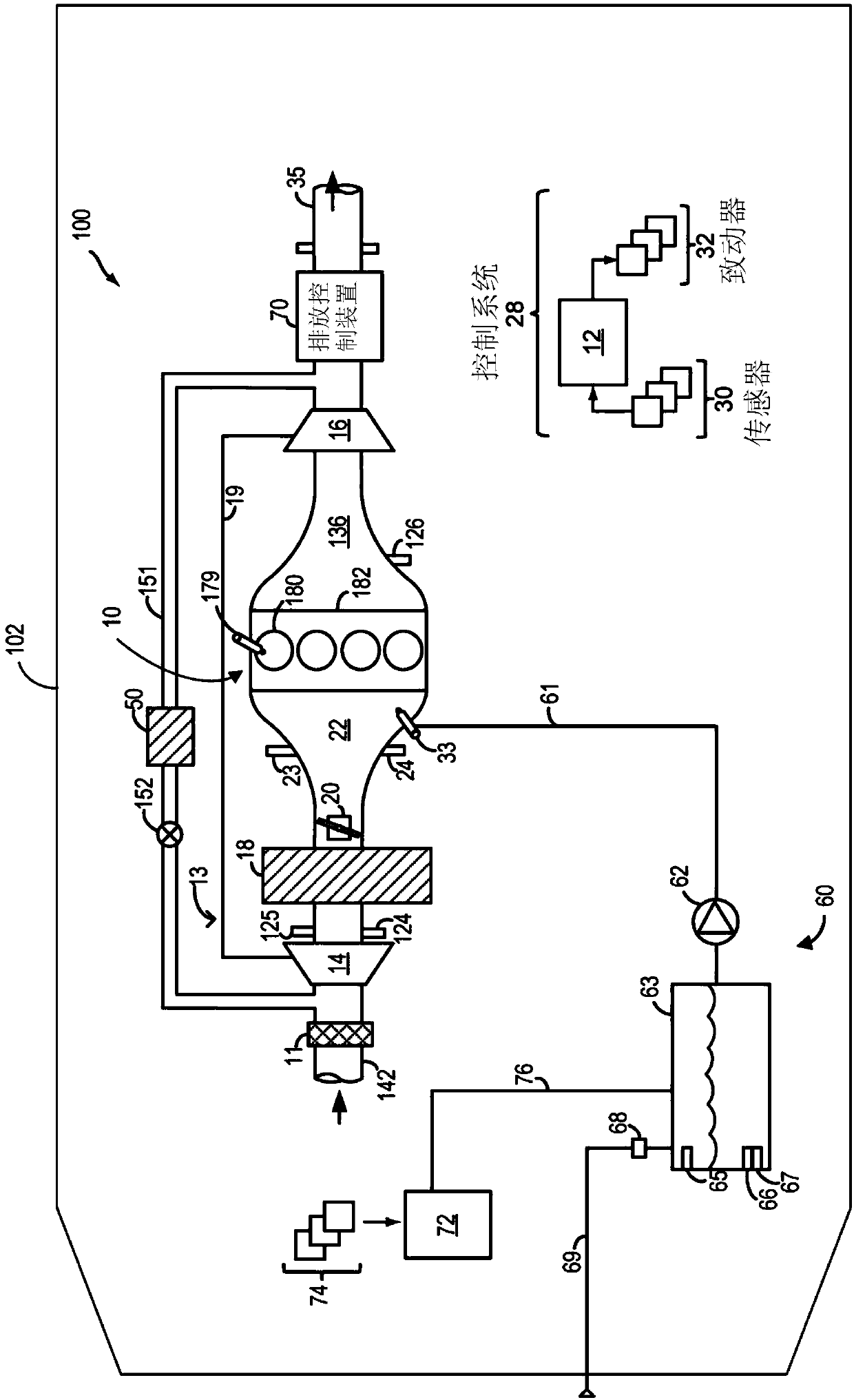

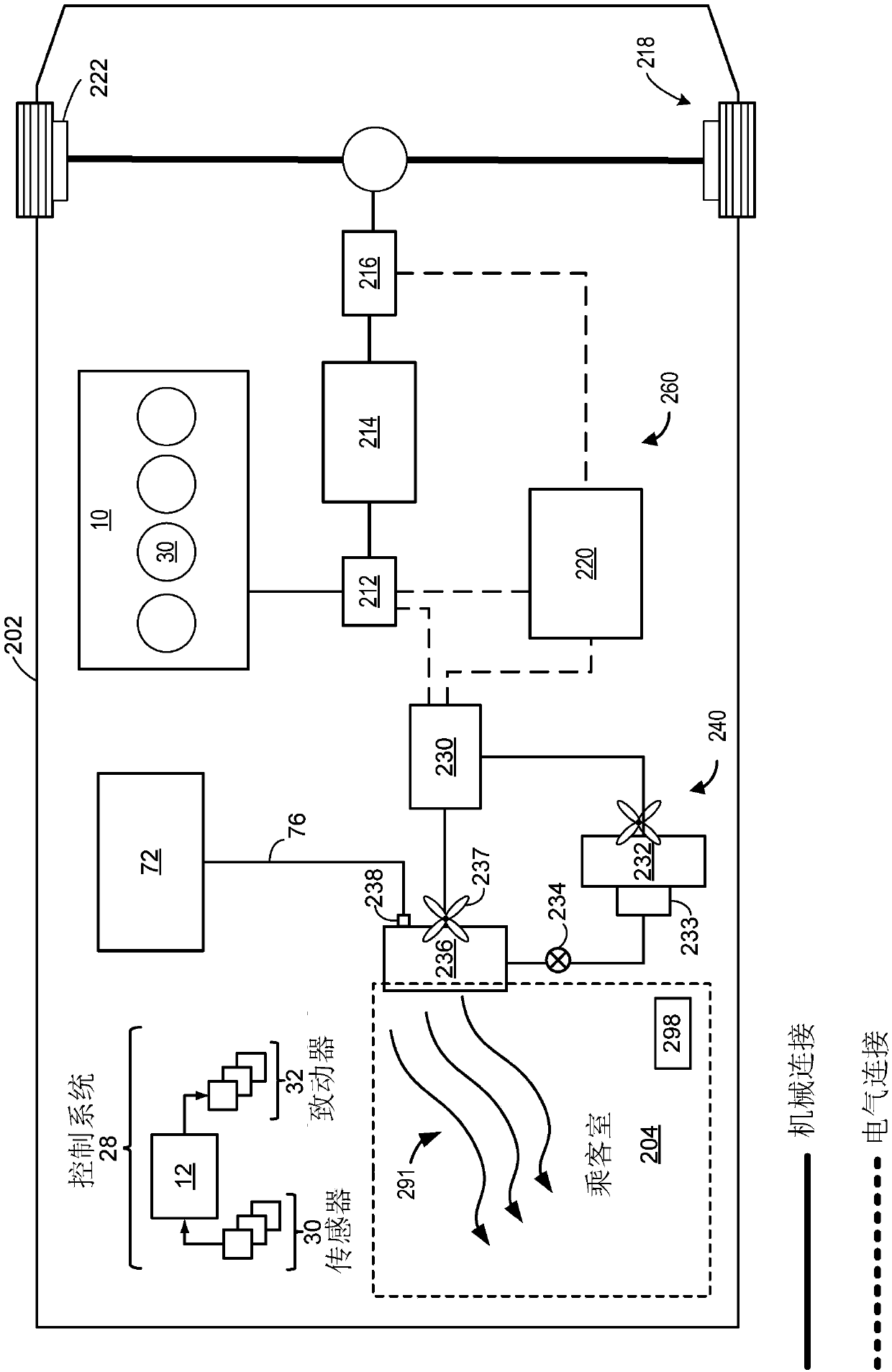

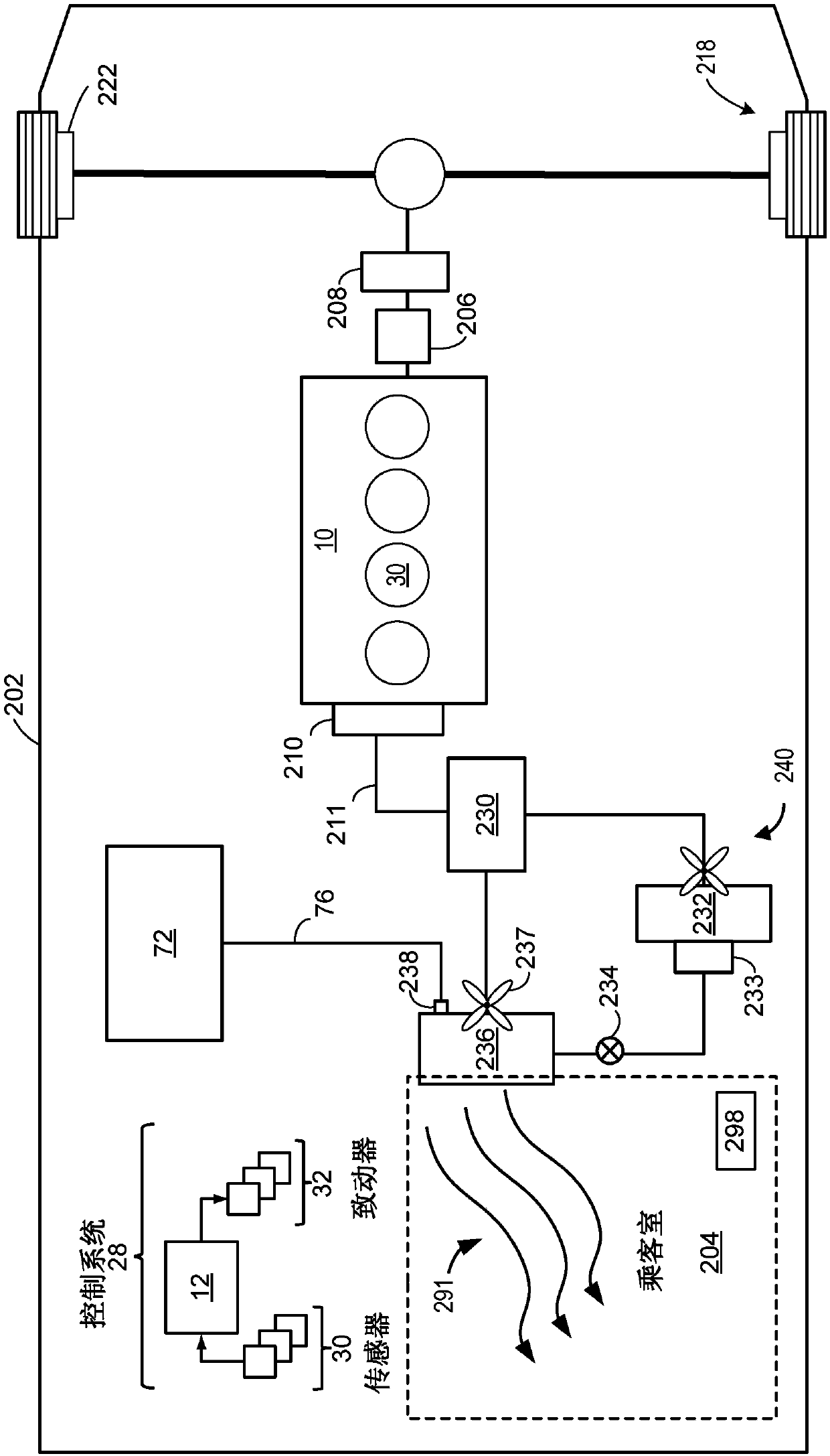

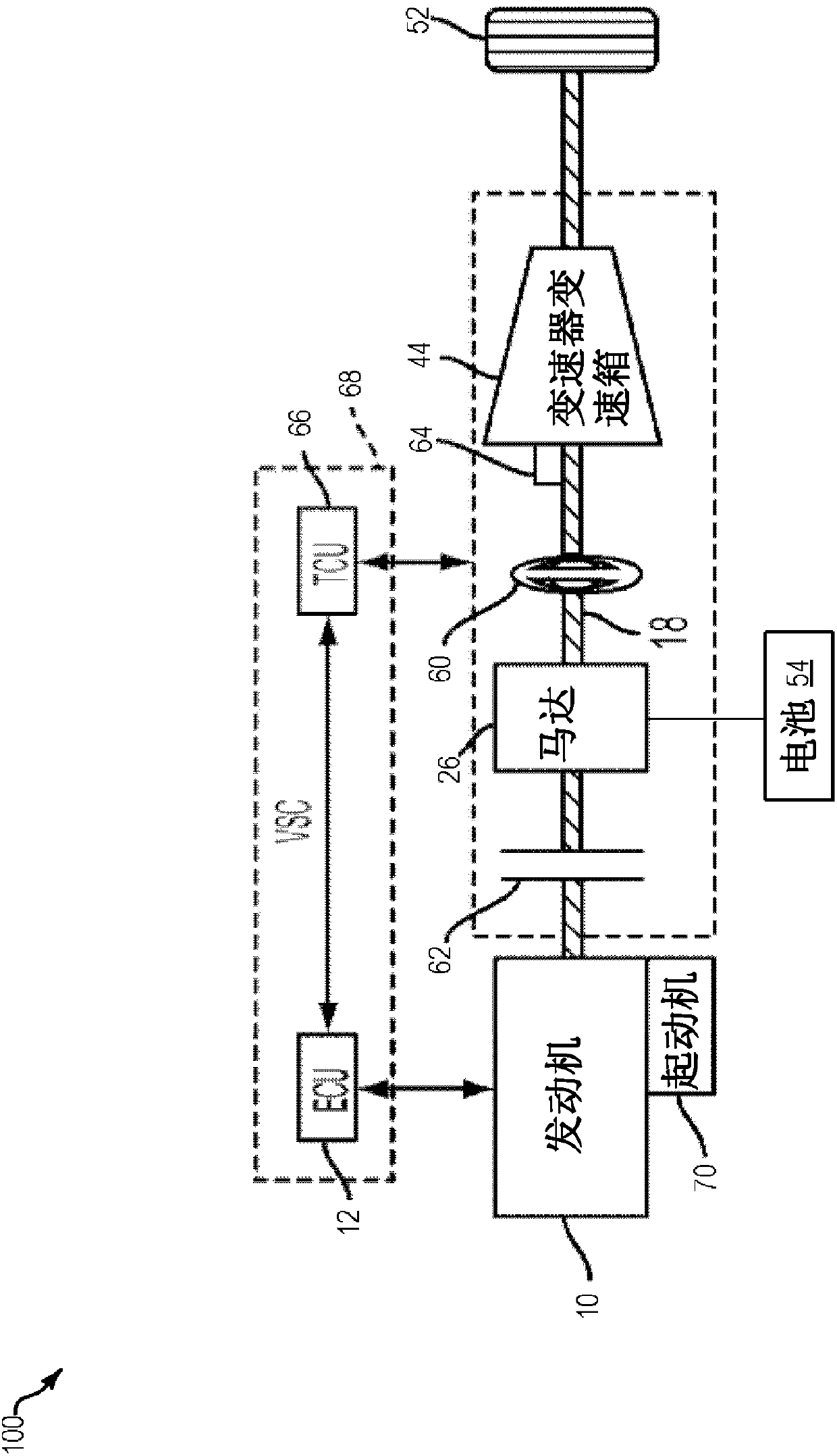

System and method for extracting water from electric air conditioning system for water injection

InactiveCN107856665AHeavy loadReduce loadHybrid vehiclesInternal combustion piston enginesBattery state of chargeRegenerative brake

The invention relates to a system and a method for extracting water from an electric air conditioning system for water injection. Methods and systems are provided for adjusting a ratio of friction toregenerative brake effort and running an electric air conditioning compressor to collect condensed water for water injection into an engine. In one example, a method may include adjusting the air conditioning compressor load of the electric AC system and the ratio of friction to regenerative brake effort based on a water level in a water storage tank of the water injection system. Further, the method may include directing energy from regenerative braking to a battery and / or to the AC compressor in response to the battery state of charge.

Owner:FORD GLOBAL TECH LLC

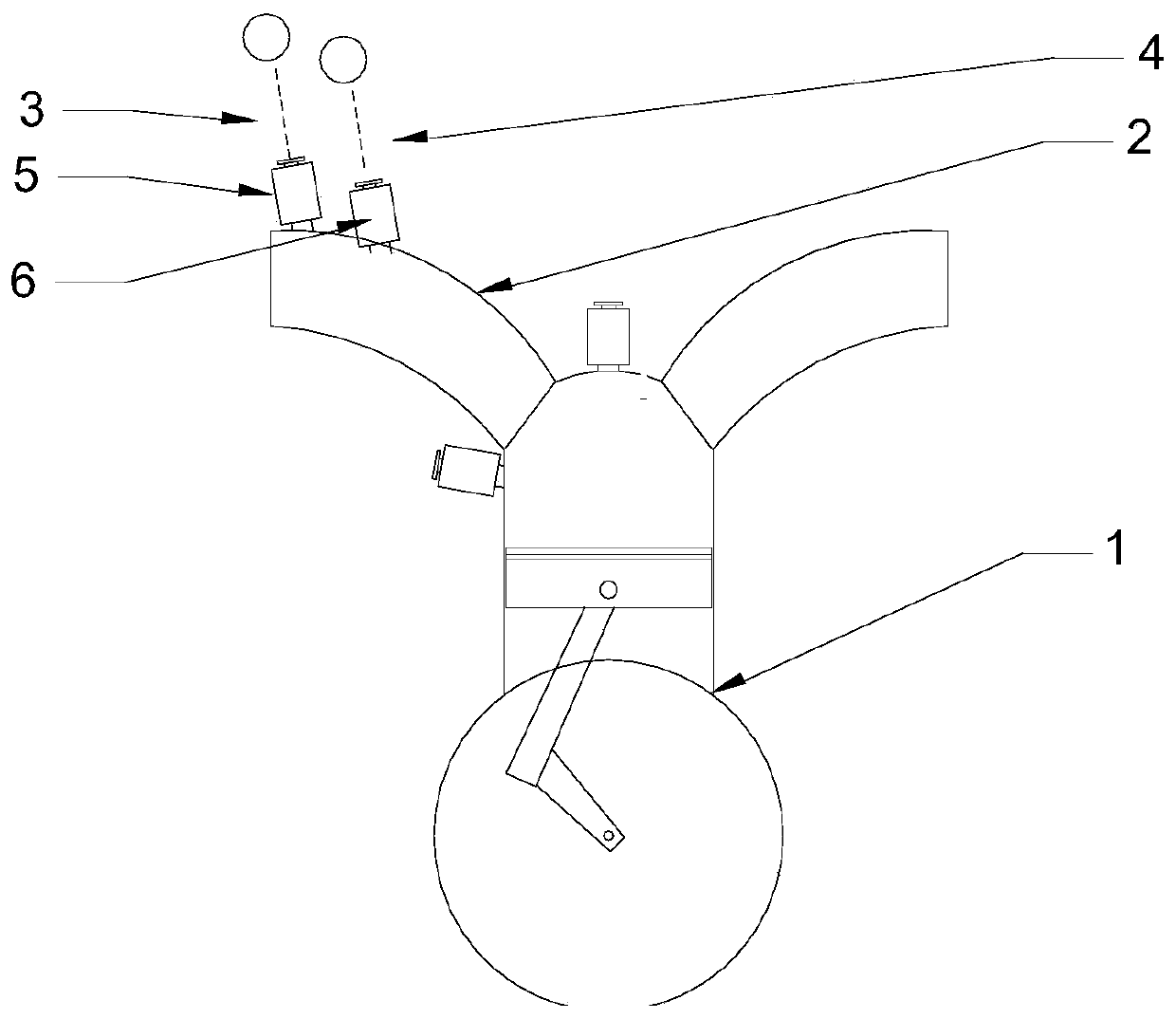

Engine intake physicochemical property adjusting structure

PendingCN110685827ABurn fasterImprove combustion efficiencyNon-fuel substance addition to fuelInternal combustion piston enginesPhysical chemistryEnvironmental engineering

The invention discloses an engine intake physicochemical property adjusting structure. The adjusting structure is arranged on an air inlet pipe of an engine and comprises a deionized water injection device and a hydrogen injection device. The deionized water injection device and the hydrogen injection device are electrically connected with an electronic control unit to control the injection amountof deionized water and hydrogen when the engine is under medium-and-small-load working conditions. Under high-load working conditions, the injection amount of the deionized water is controlled. By means of the adjusting structure, the combustion efficiency of the engine can be effectively improved, and the emission amount of carbon oxide is reduced.

Owner:HEFEI UNIV OF TECH

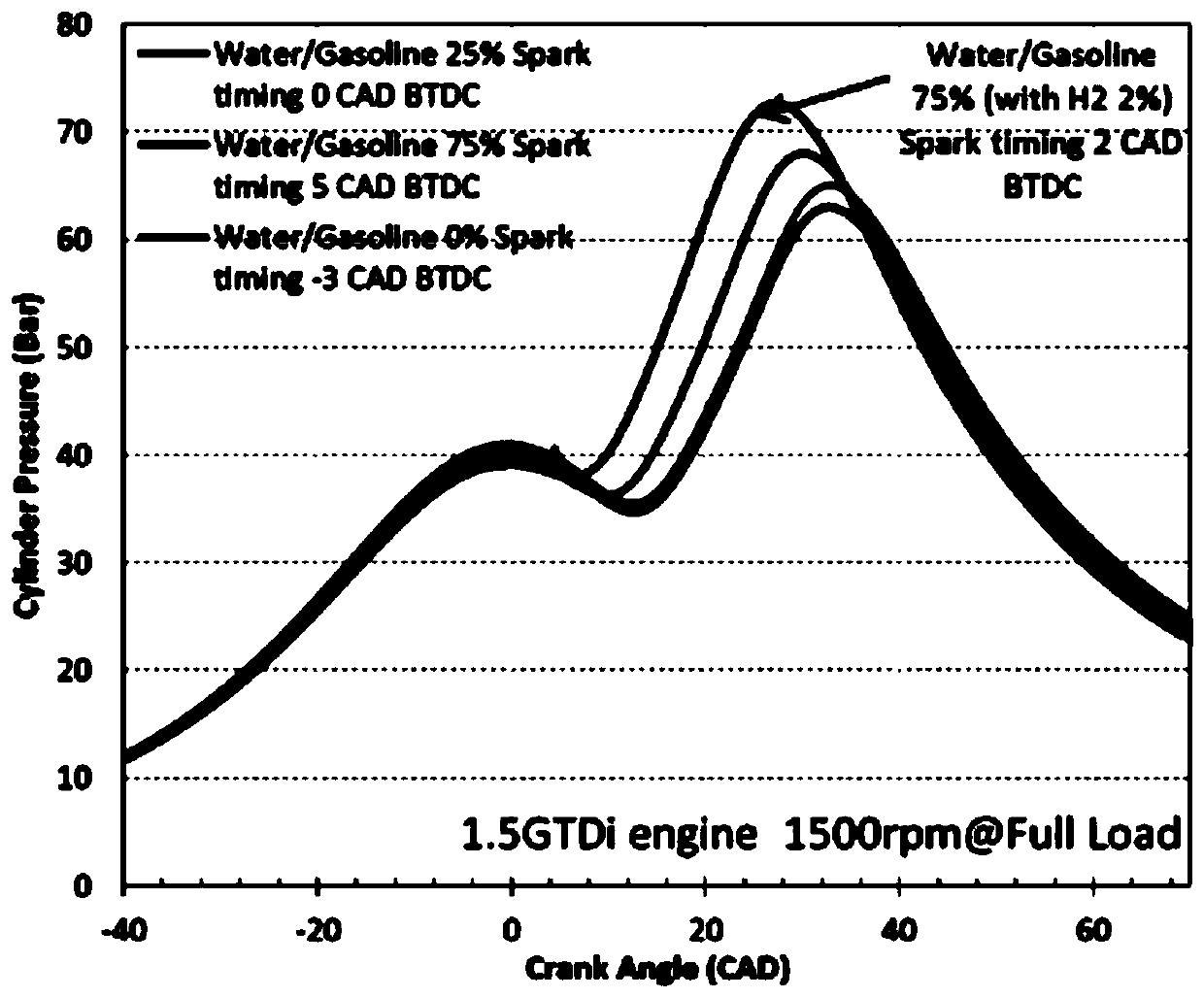

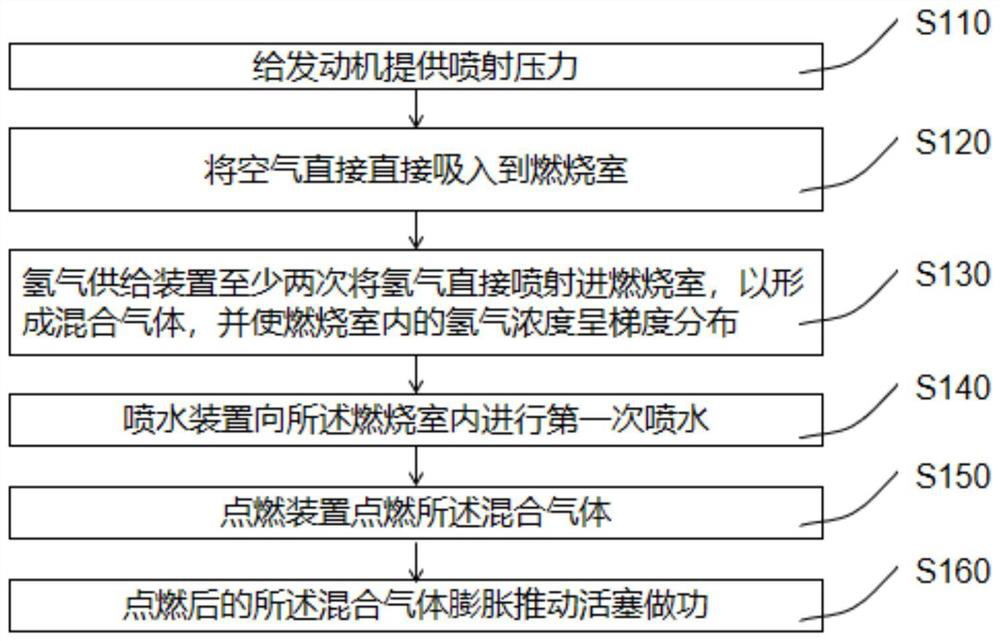

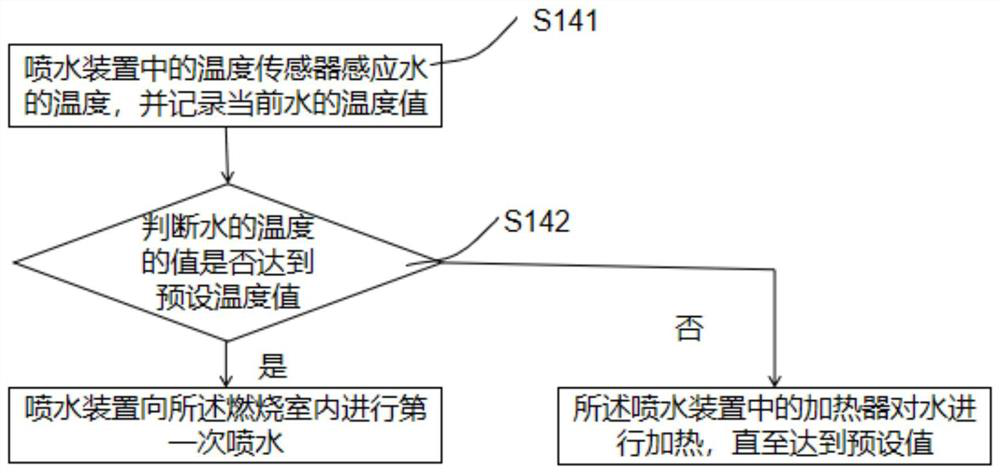

Engine system and engine fuel injection method

PendingCN113565626AControl burn rateFast burning rateInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberNitrogen oxides

The invention provides an engine system and an engine fuel injection method. A hydrogen supply device and a water supply device are directly connected with a combustion chamber to directly inject hydrogen and water into the combustion chamber correspondingly, hydrogen is injected into the combustion chamber at least two times so that the concentration of hydrogen in the combustion chamber can be distributed in a gradient manner, in this way, the over-high combustion rate of hydrogen can be controlled, then knocking is prevented, and therefore an engine can work in a large-load working environment; and furthermore, water is directly injected into the combustion chamber through a water injection device, so that the combustion speed of hydrogen is controlled, the combustion speed of hydrogen is prevented from being too high, knocking is further prevented, the combustion temperature can be reduced, and therefore generation of nitrogen oxide pollution gas is reduced, and meanwhile the engine system and the engine fuel injection method are beneficial to enhancing expansion acting and improving heat efficiency.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

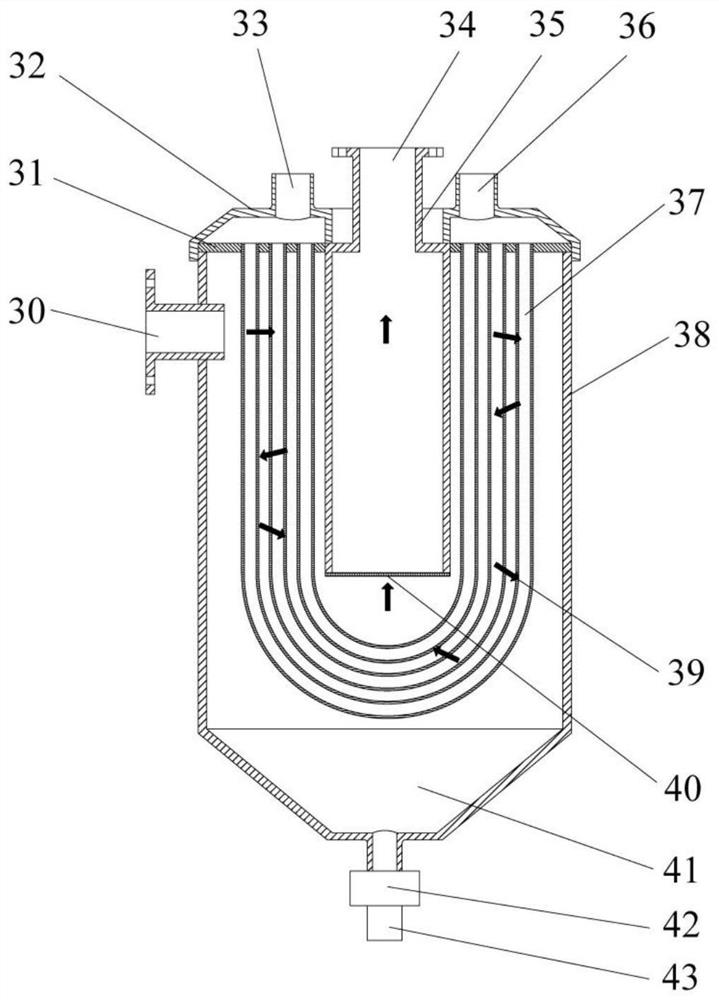

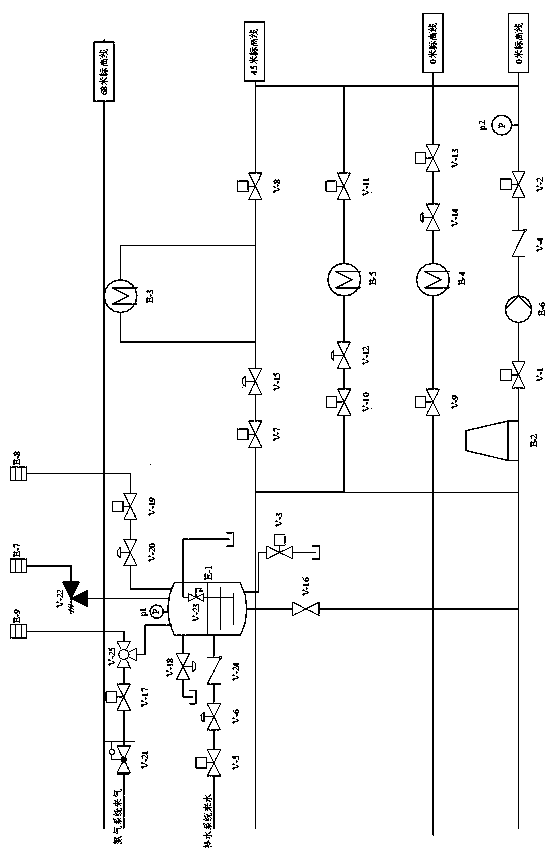

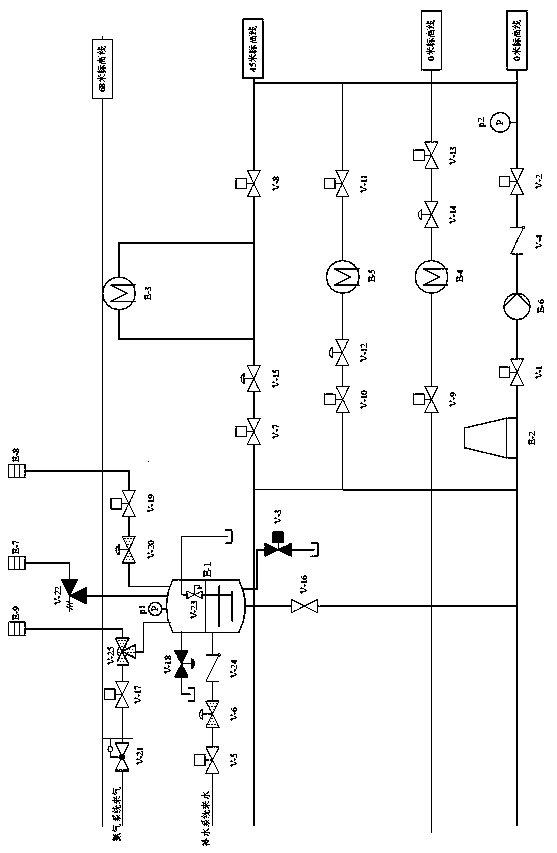

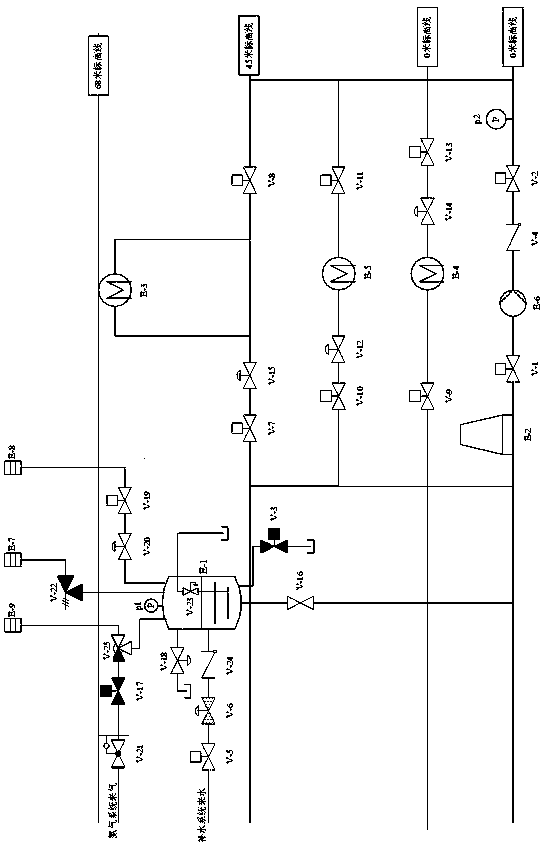

High-position arrangement turboset auxiliary engine cooling water device based on pressure regulating water tank

PendingCN111504080AGuaranteed water injection pressureLower base pressureSteam/vapor condensersMachines/enginesEngineeringMechanical engineering

The invention relates to a high-position arrangement turboset auxiliary engine cooling water device based on a pressure regulating water tank. The high-position arrangement turboset auxiliary engine cooling water device based on the pressure regulating water tank comprises an E-1 pressure regulating water tank, an air inlet device installed on one side of the top of the E-1 pressure regulating water tank, an exhausting pressure maintaining device installed on the other side of the top of the E-1 pressure regulating water tank, a normal pressure overflow device installed on one side of the upper part of the E-1 pressure regulating water tank, a V-23 draining ball cock installed in the E-1 pressure regulating water tank and a water outlet device arranged on the bottom of the E-1 pressure regulating water tank. According to the high-position arrangement turboset auxiliary engine cooling water device based on the pressure regulating water tank, safety and stability of the process from static water injection, device starting, running, adjusting and stopping of the high-position arrangement turboset auxiliary engine cooling water system can be guaranteed, the requirement for pressure andflow of cooling water users can be met, the working conditions can be automatically switched, the requirements of modern power plant APS and high-automation level are met, and the requirements for safety, reliability and long-term running of a unit can be guaranteed.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

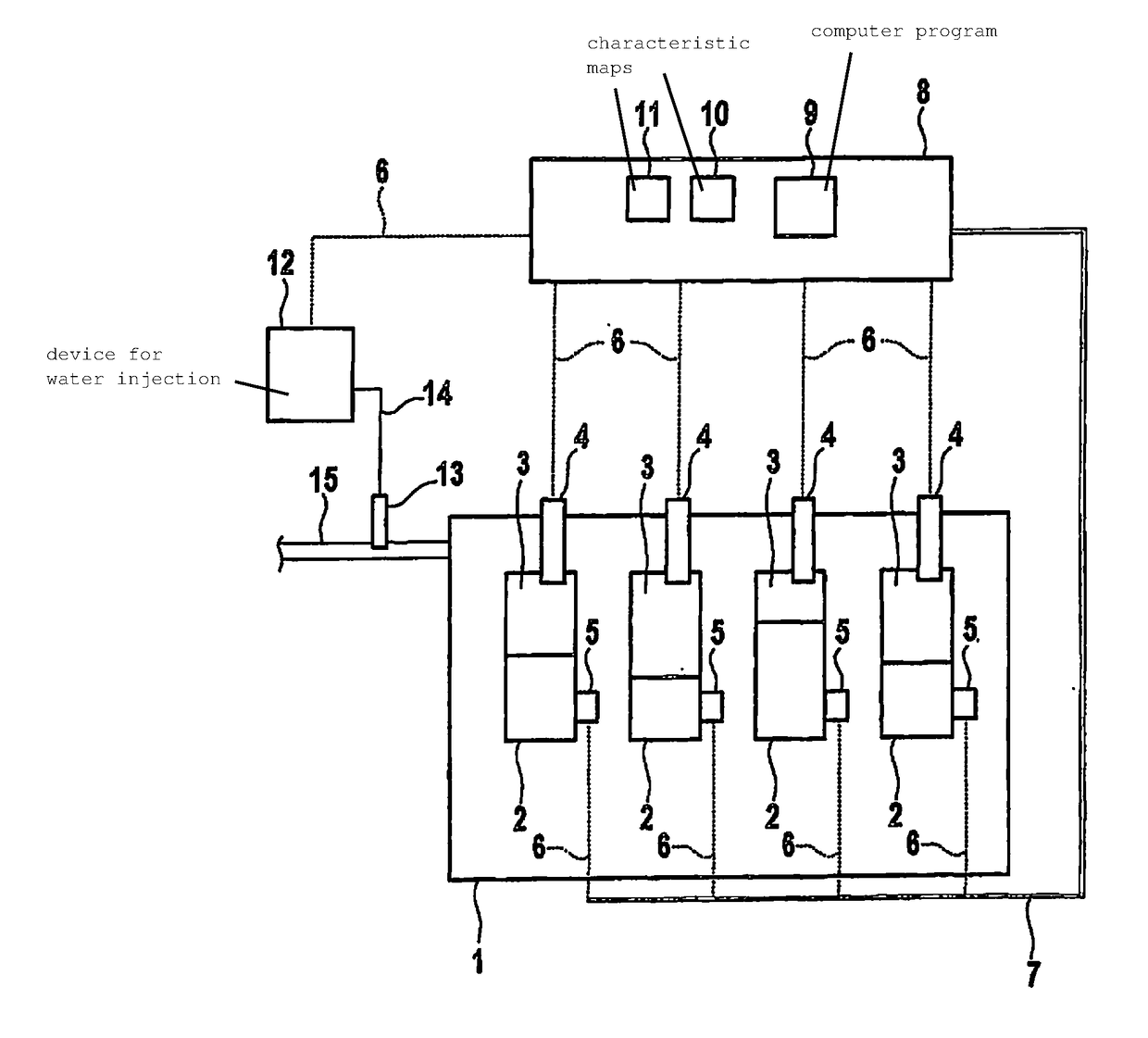

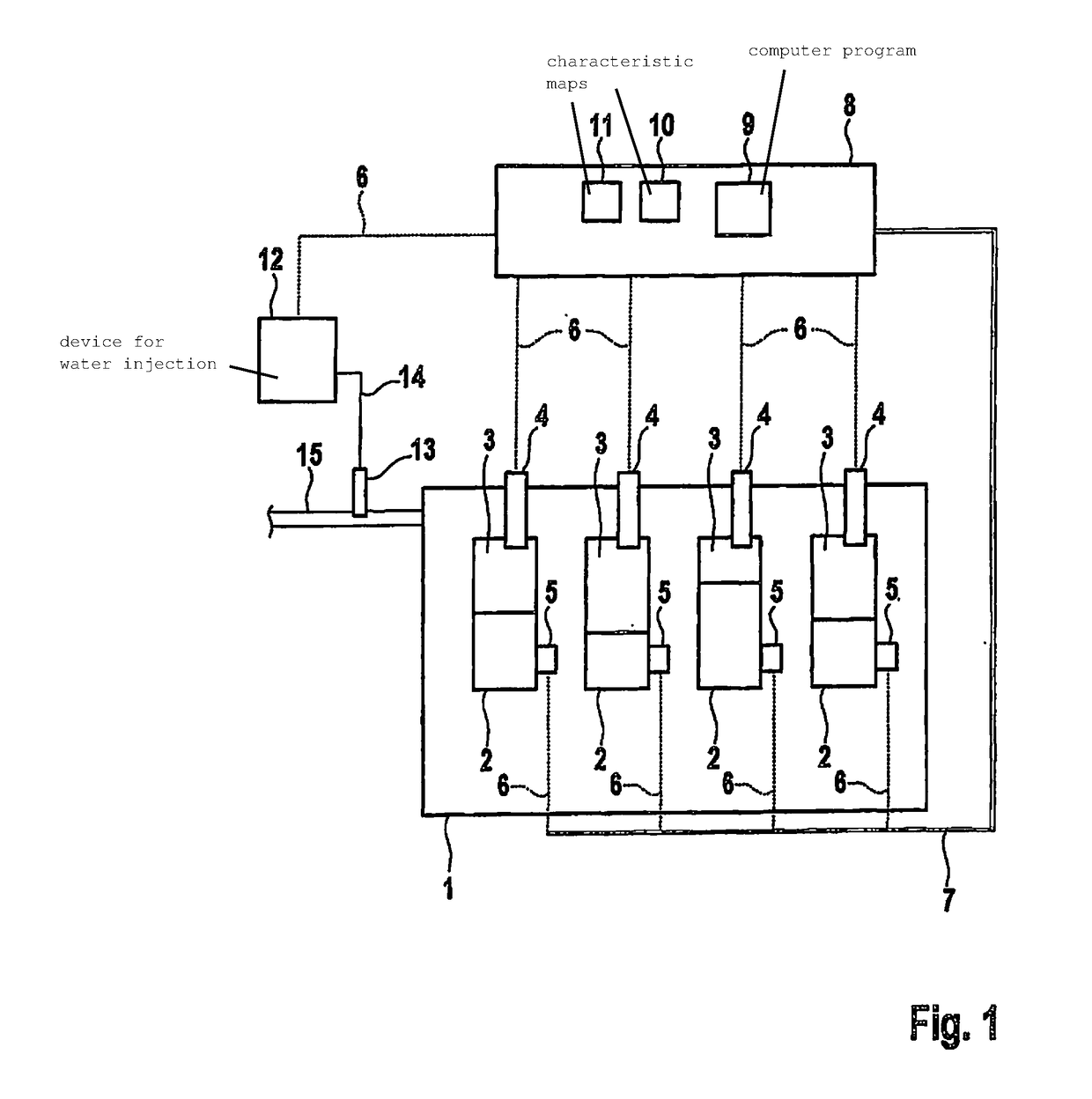

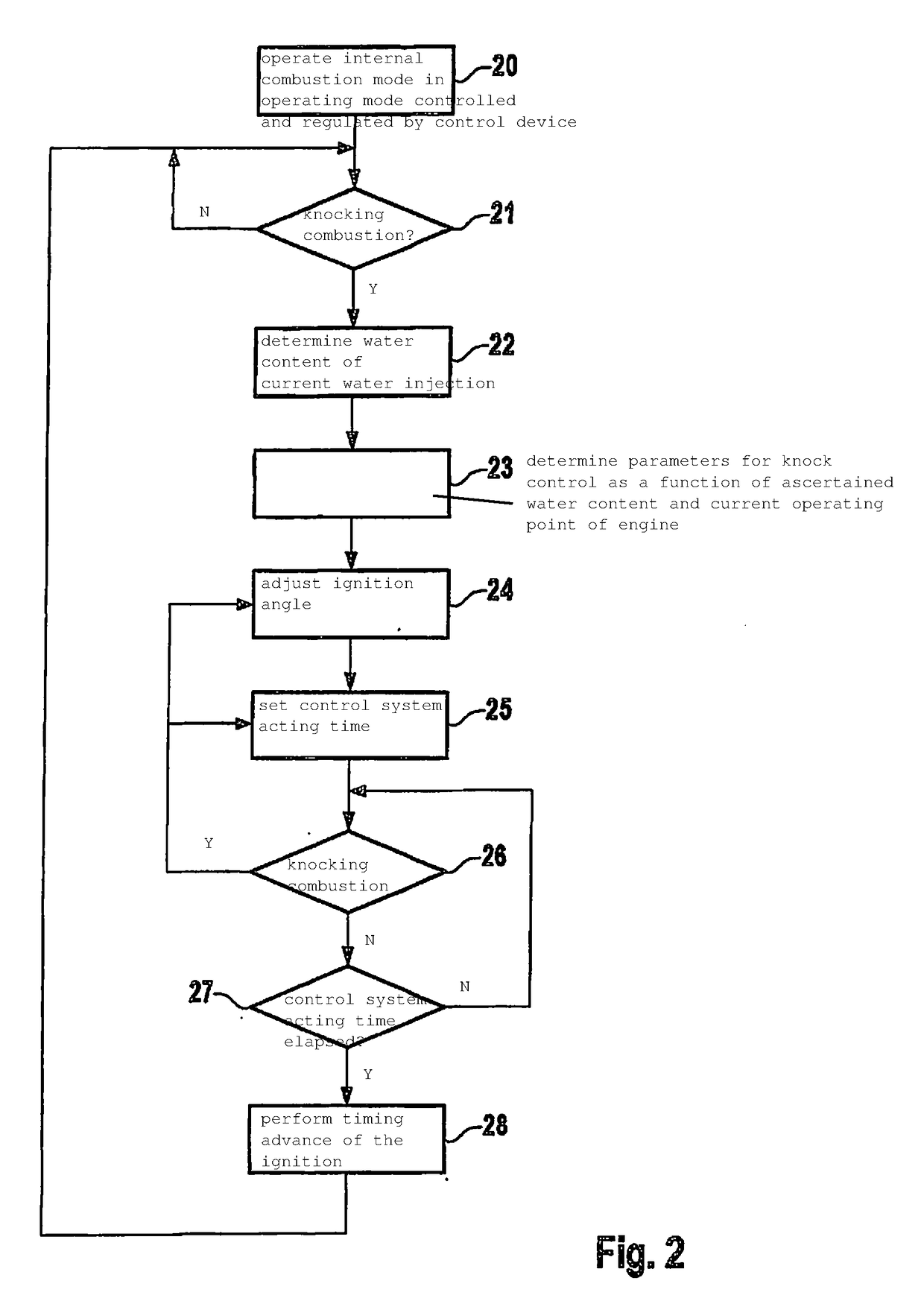

Method for knock control of an internal combustion engine

ActiveUS20180112631A1Improved operationLess controlledElectrical controlInternal combustion piston enginesWater contentEngineering

Owner:ROBERT BOSCH GMBH

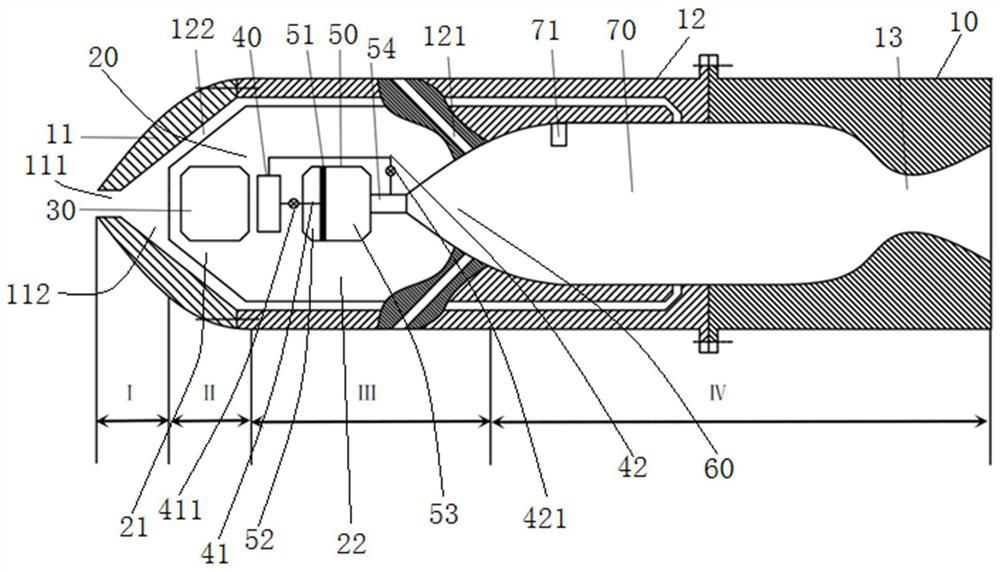

Metal hydrogen storage powder water ramjet engine

PendingCN113882965AAvoid cloggingExcellent thrust performanceContinuous combustion chamberTurbine/propulsion fuel valvesRamjetCombustion chamber

The invention discloses a metal hydrogen storage powder water ramjet engine. The engine comprises a shell, a pressurization system and a powder storage tank. A storage cavity, a conical mixing cavity, a combustion chamber and a tail spraying cavity are sequentially distributed in the center of the shell in the axial direction. The pressurization system and the powder storage tank are arranged in the storage cavity; the pressurization system comprises a supercharger, a main pressurization pipe and branch pressurization pipes; a piston is arranged in the powder storage tank and divides the powder storage tank into a pressurizing chamber and a powder storage chamber; a powder spraying pipe is arranged at the right side of the powder storage chamber; and water injection nozzles are uniformly distributed at the position, at the periphery of the conical mixing cavity, of the shell along the circumferential direction. Metal hydrogen storage powder is wrapped by pressurization gas and enters the combustion chamber through the powder spraying pipe through the pressurization system, and the powder is prevented from blocking the powder spraying pipe; and the metal hydrogen storage powder entering the combustion chamber is fully mixed with water mist sprayed into the combustion chamber through the water injection nozzles. In addition, under the combustion-supporting effect of a small amount of oxygen, the ignition difficulty is remarkably reduced, the reaction stability is enhanced, and the thrust performance is better.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

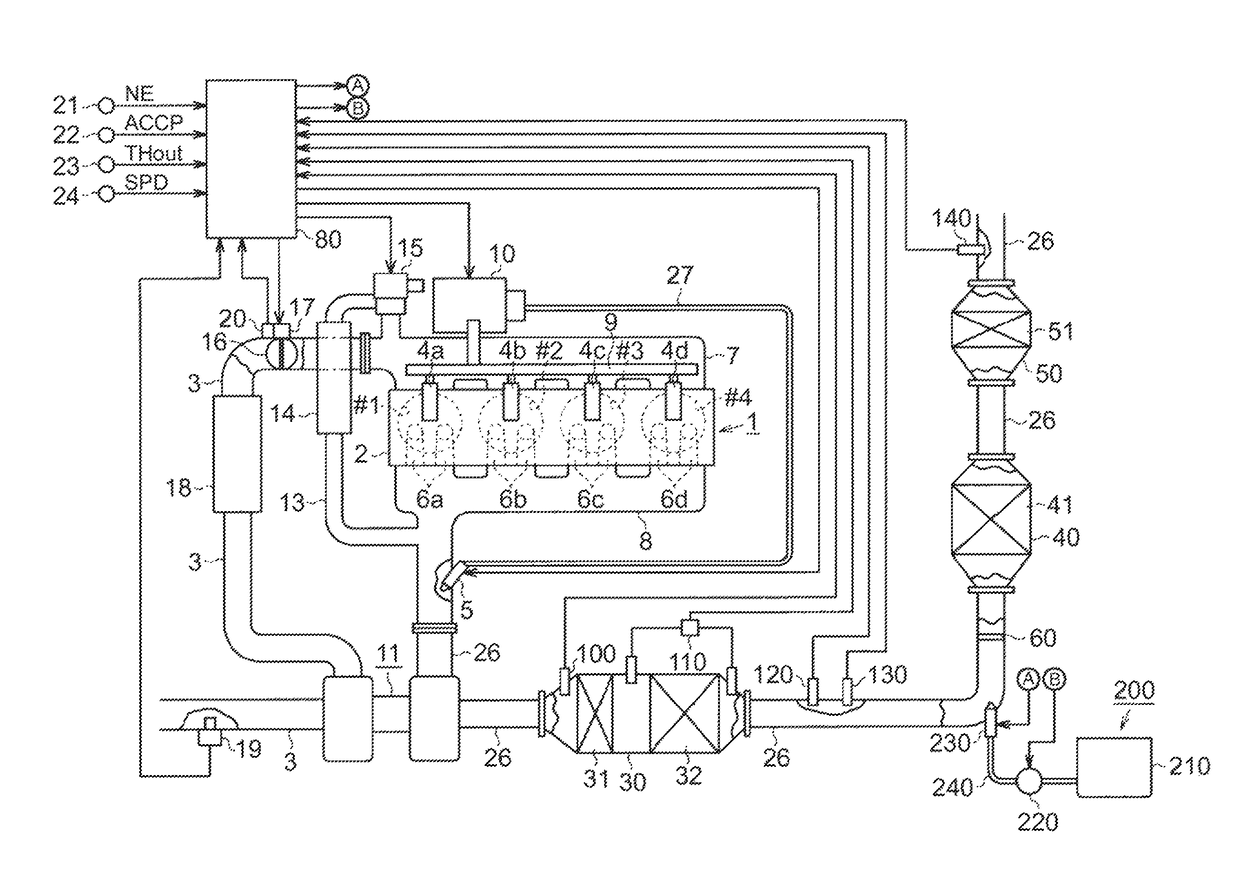

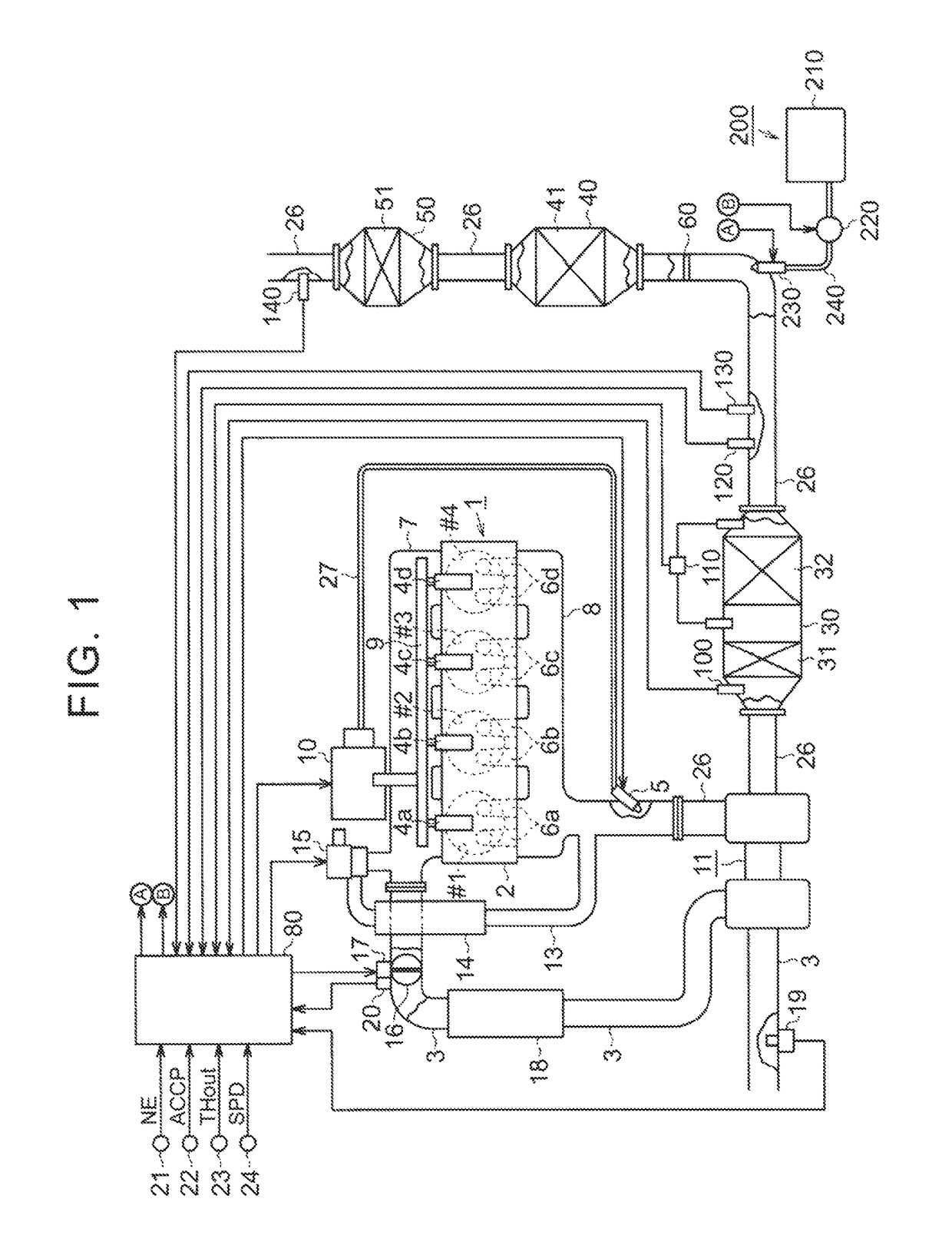

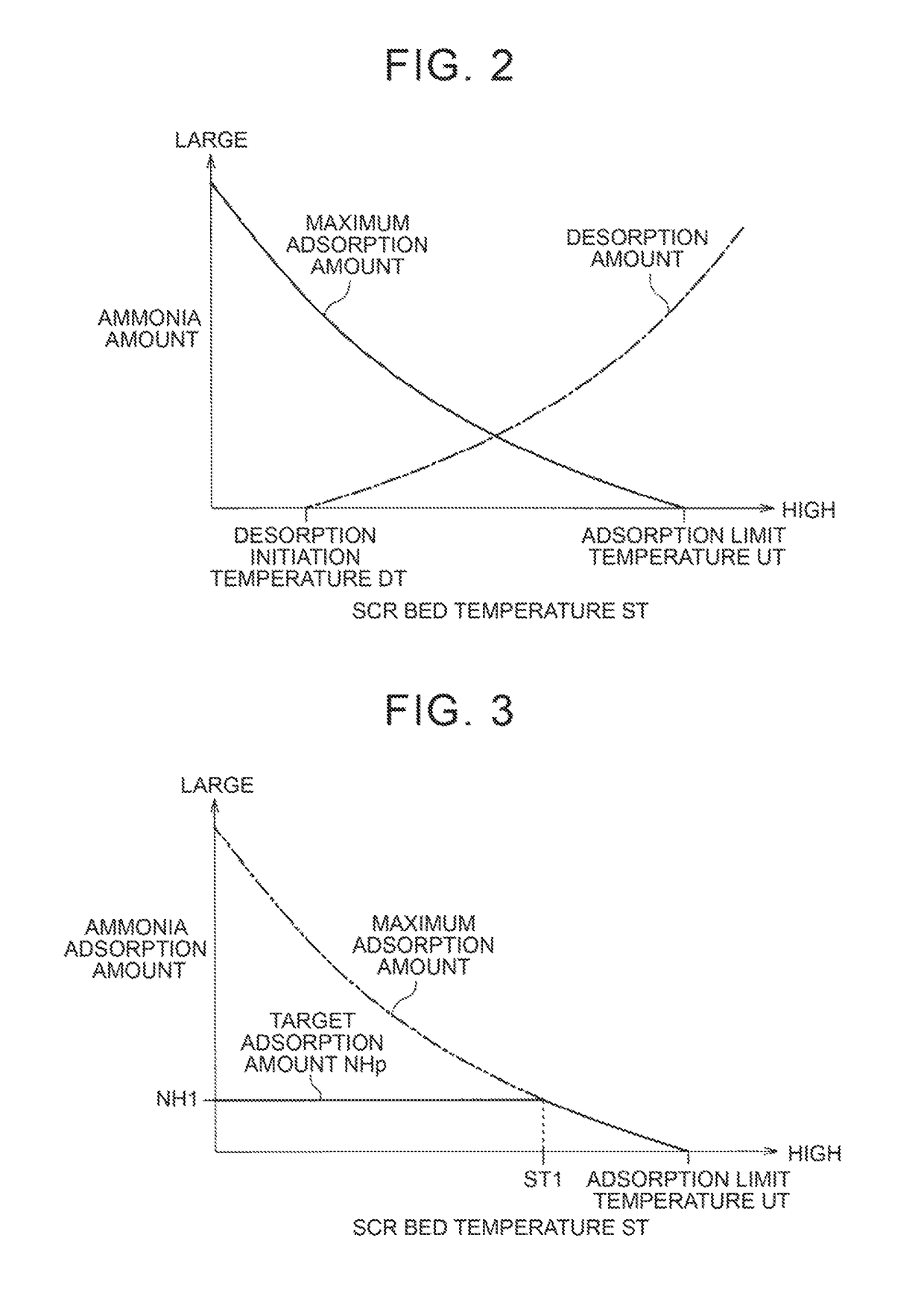

Exhaust gas control apparatus for internal combustion engine

InactiveUS9856771B2Increase the number ofReliable executionElectrical controlInternal combustion piston enginesPtru catalystExhaust fumes

An exhaust gas control apparatus for an internal combustion engine includes a urea water injection valve, a catalyst disposed in an exhaust passage downstream of the injection valve, and an electronic control unit. The injection valve is configured to add urea water to exhaust gas. The catalyst is configured to adsorb ammonia generated from the urea water. The electronic control unit is configured to (i) set a target adsorption amount of the ammonia adsorbed on the catalyst, (ii) control the injection valve such that the amount of the urea water added to the exhaust gas becomes an addition amount calculated based on the target adsorption amount, and (iii) execute an initialization processing for decreasing the amount of the ammonia adsorbed on the catalyst to (zero) when an integrated value of the amount of the NOx flowing into the catalyst is equal to or higher than a predetermined value.

Owner:TOYOTA JIDOSHA KK

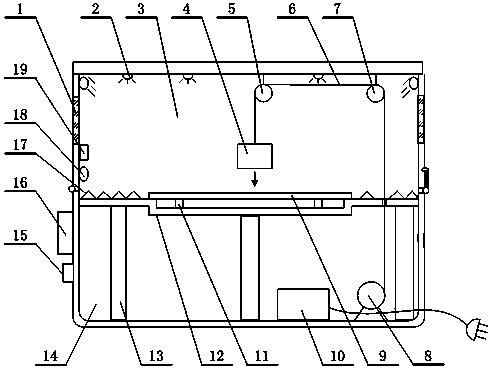

Carbon cleaning machine for cleaning deposited carbon of automobile engine

ActiveCN112096519AEasy to replaceReduce the temperatureMachines/enginesEngine componentsEnvironmental engineeringAutomotive engine

The invention relates to the technical field of carbon cleaning devices, in particular to a carbon cleaning machine for cleaning deposited carbon of an automobile engine. The carbon cleaning machine can effectively reduce the content of water vapor in gas, improve the purity of the gas and avoid the influence of the water vapor on the combustion state of the gas by drying oxyhydrogen gas exhaustedinto the automobile engine, and is convenient for full combustion of the oxyhydrogen gas in the engine to improve the carbon cleaning effect and improve the practicability and reliability. The carboncleaning machine comprises a water tank, four sets of support legs, a cover plate, a water outlet pipe, a water outlet valve and a U-shaped pipe; the four sets of support legs are mounted at the bottom of the water tank; the left front side of the top of the water tank communicates with a water injection port; the cover plate covers the water injection port; the water outlet pipe is mounted on the front lower side of the water tank and communicates with the interior of the water tank; the water outlet valve is mounted on the water outlet pipe; and the U-shaped pipe is located in the water tank.

Owner:山东艾泰克环保科技股份有限公司

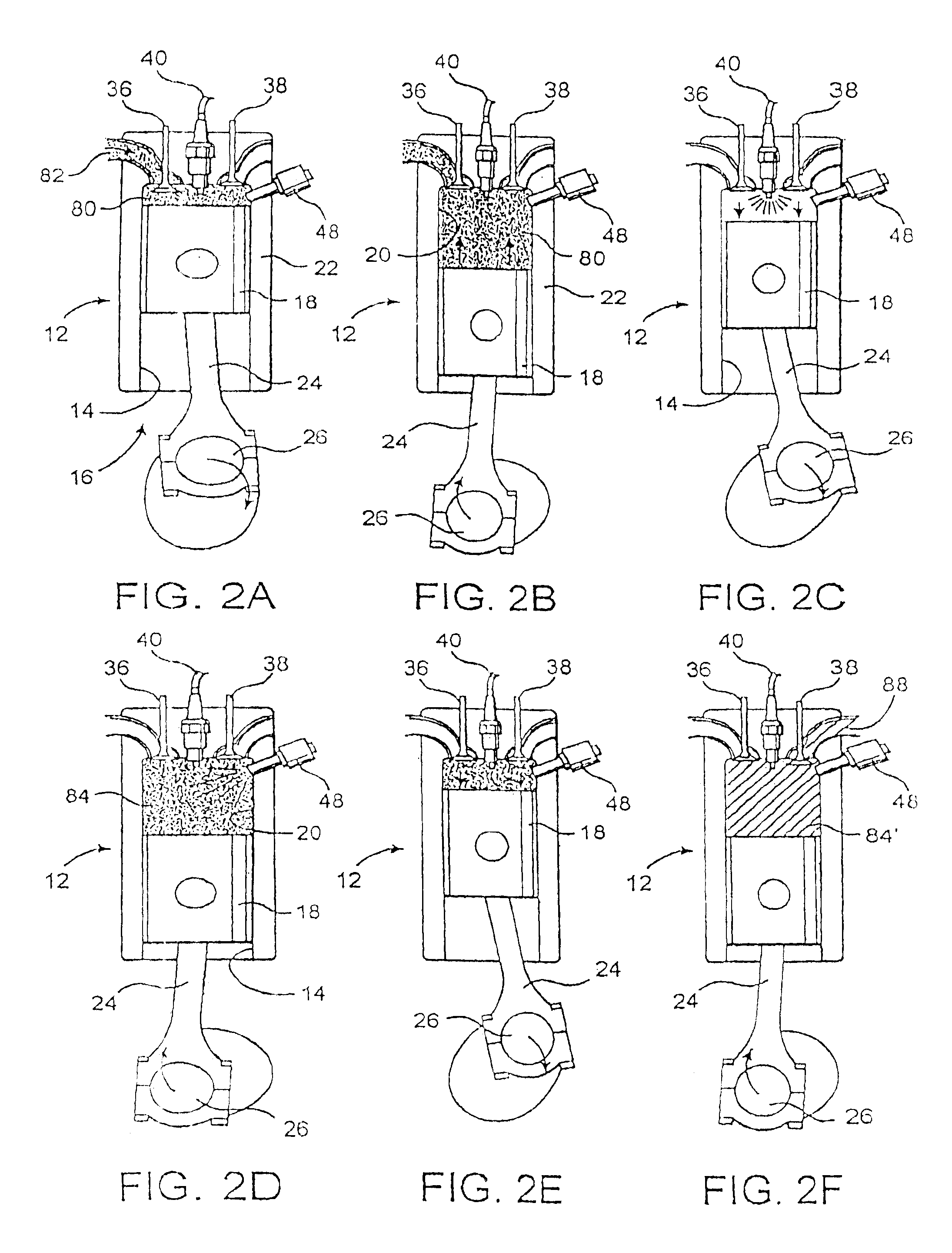

Water injection to increase hydrogen production by on-board reforming of fuel for automotive internal combustion engines

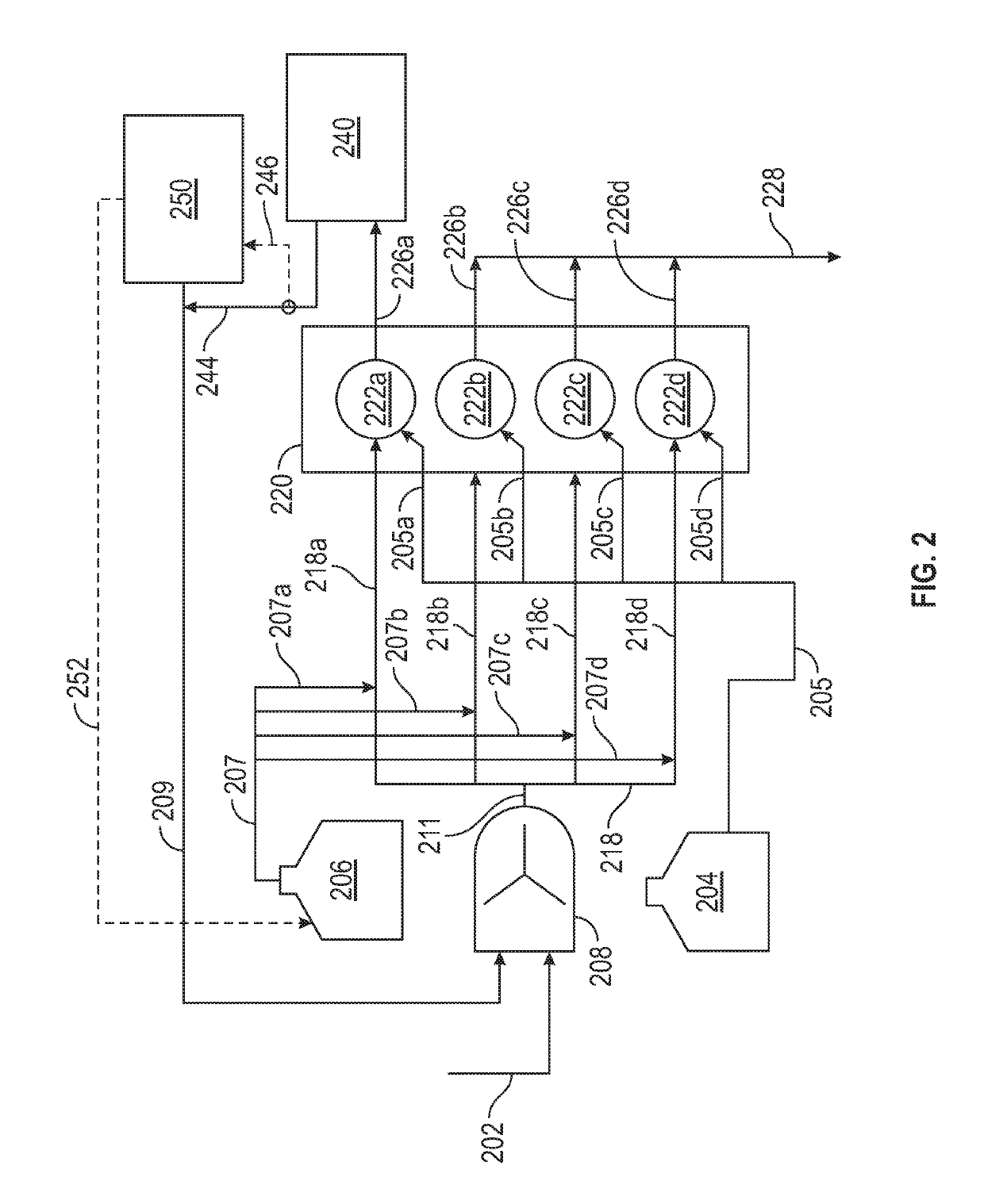

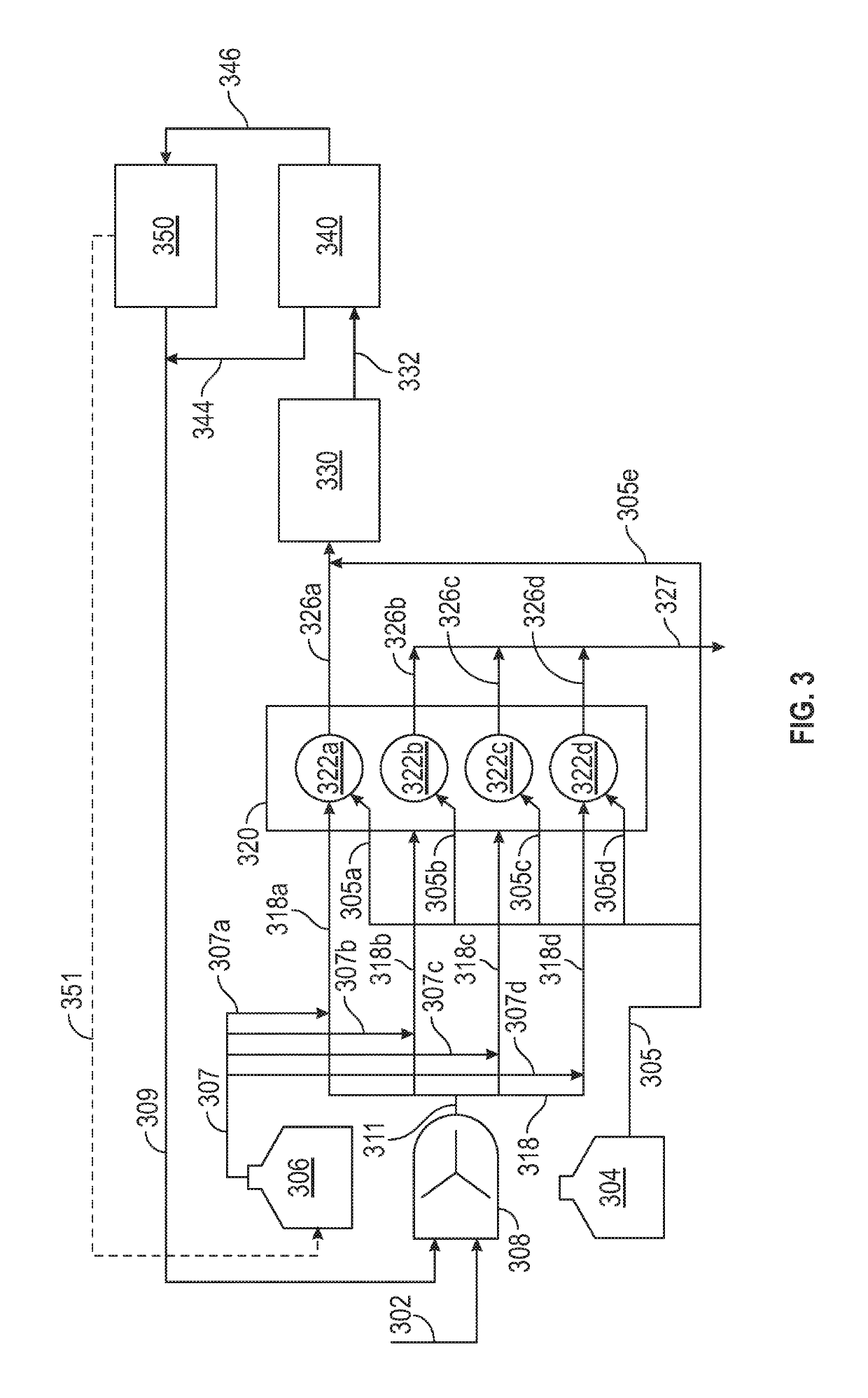

The performance of an automotive gasoline fueled spark-ignited internal combustion engine (ICE) optionally operated with a dedicated exhaust gas recycle system is enhanced by reforming the fuel in the presence of injected water to increase the yield of hydrogen which permits higher compression ratios and suppresses engine knock associated with pre-ignition of the fuel. Reforming can occur (a) in the cylinder with the reaction of a fuel-rich mixture and steam from the water injected into the intake manifold of one or more dedicated exhaust gas recirculation cylinders; (b) in a catalytic reformer located upstream of the engine; (c) in a catalytic reformer located downstream of the engine that receives fuel and the exhaust gas stream from the dedicated exhaust gas recirculation cylinder(s), and returns cooled reformate to the intake manifold; and (d) in a catalytic reformer that receives fuel and the exhaust gas stream from the engine exhaust gas manifold, and delivers reformate to the intake manifold.

Owner:SAUDI ARABIAN OIL CO

System and method for extracting water from a mechanical air conditioning system for water injection

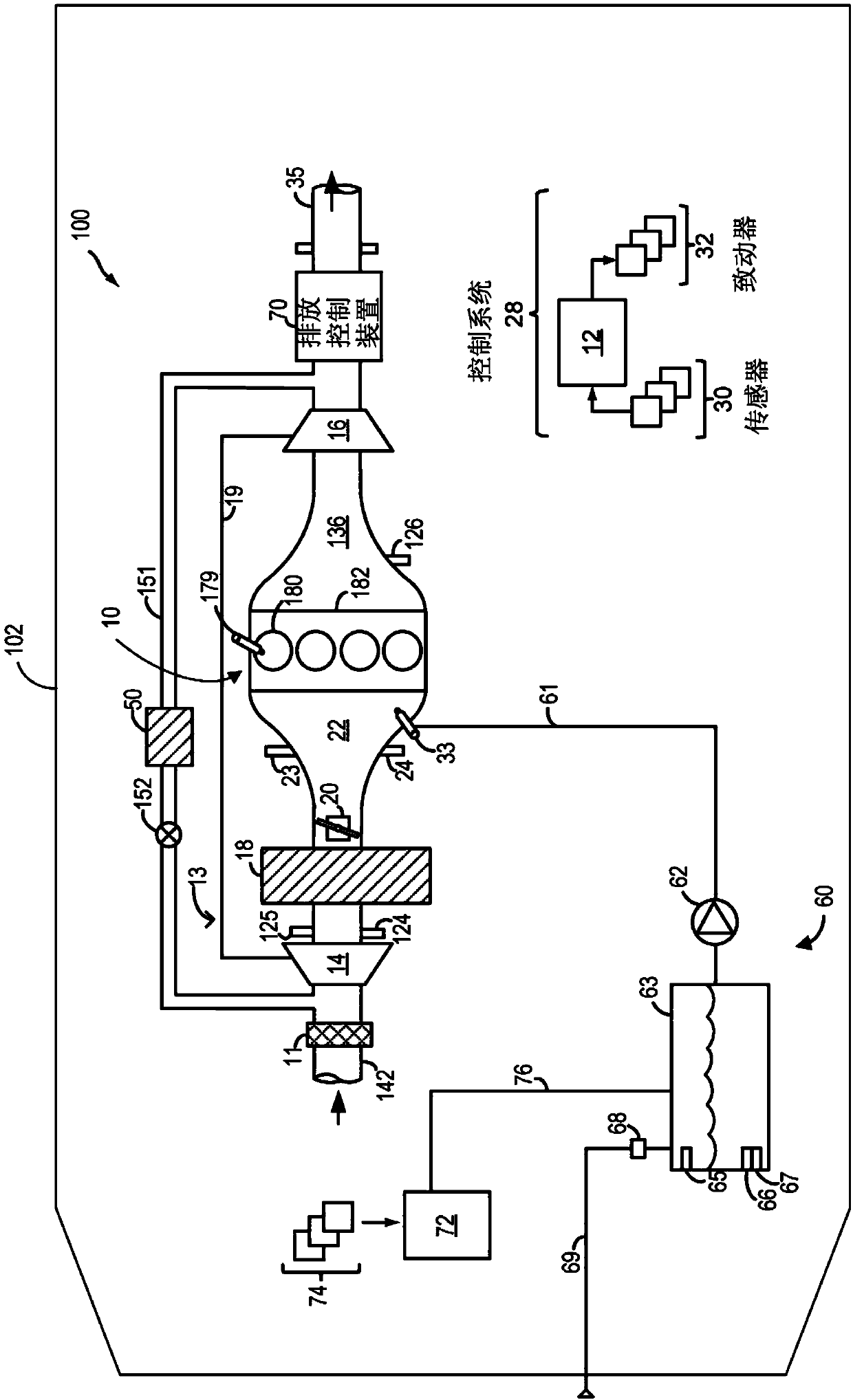

InactiveCN107859566AAir-treating devicesNon-fuel substance addition to fuelWater storageDriver/operator

The invention relates to a system and a method for extracting water from a mechanical air conditioning system for water injection. The invention provides the method and the system for adjusting an amount of friction brake effort and an air conditioning compressor load to collect water for water injection into an engine. In one example, the method may include adjusting the AC compressor load of a mechanical air conditioning system and an amount of friction brake effort based on a water level in a water storage tank of the water injection system. Further, the method may include adjusting a ratioof the AC compressor load to friction brake effort to deliver a driver demanded brake effort.

Owner:FORD GLOBAL TECH LLC

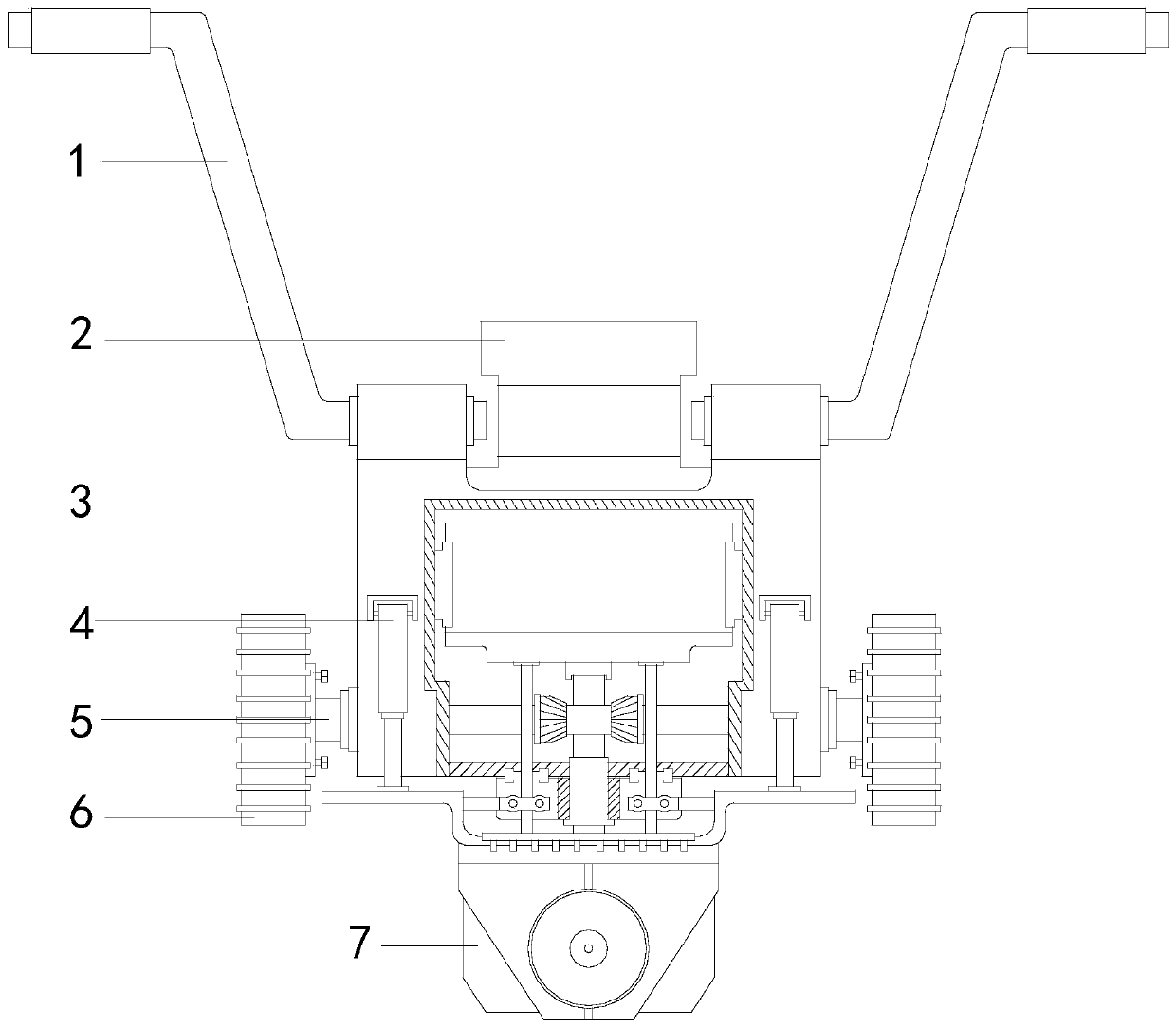

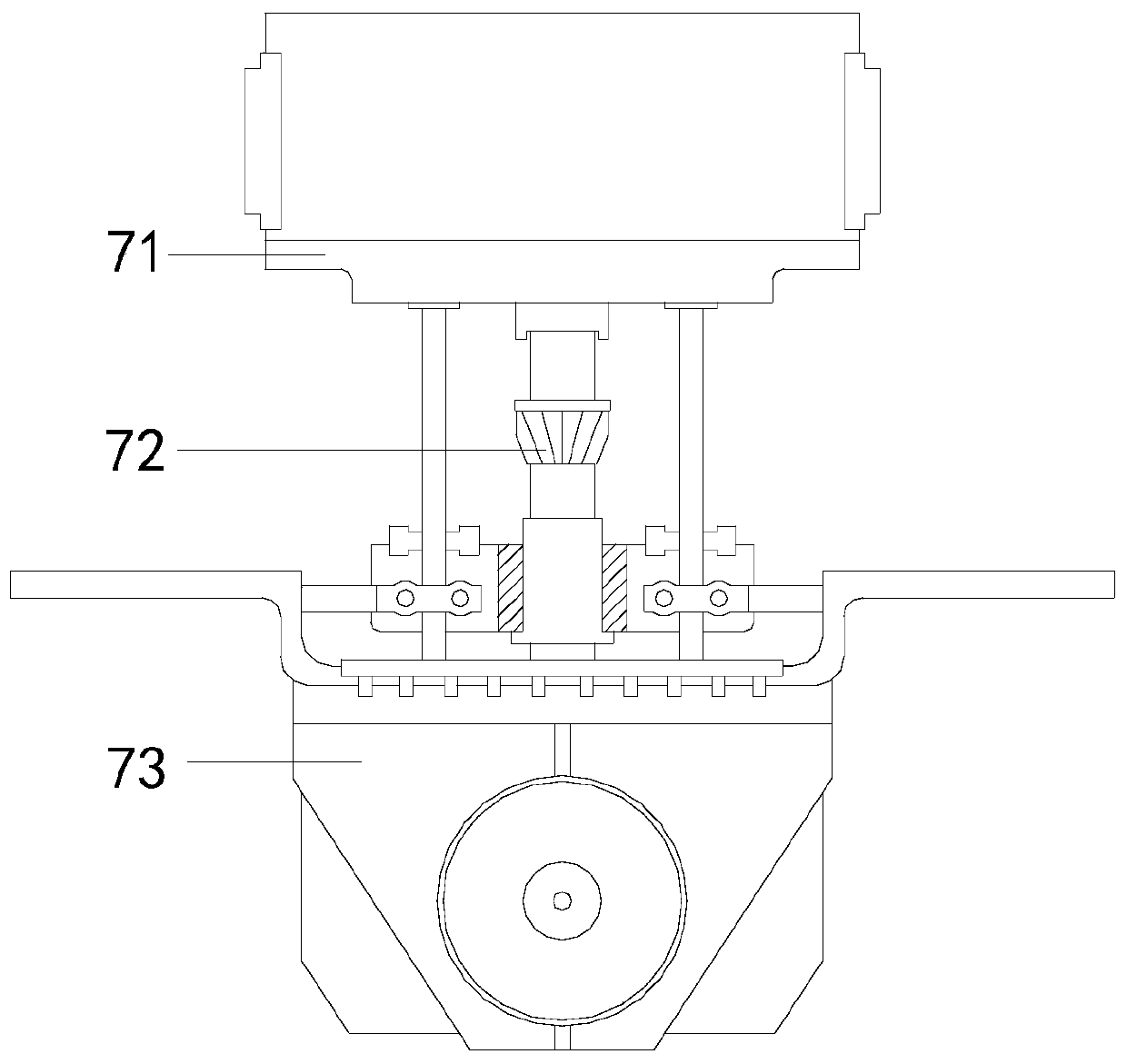

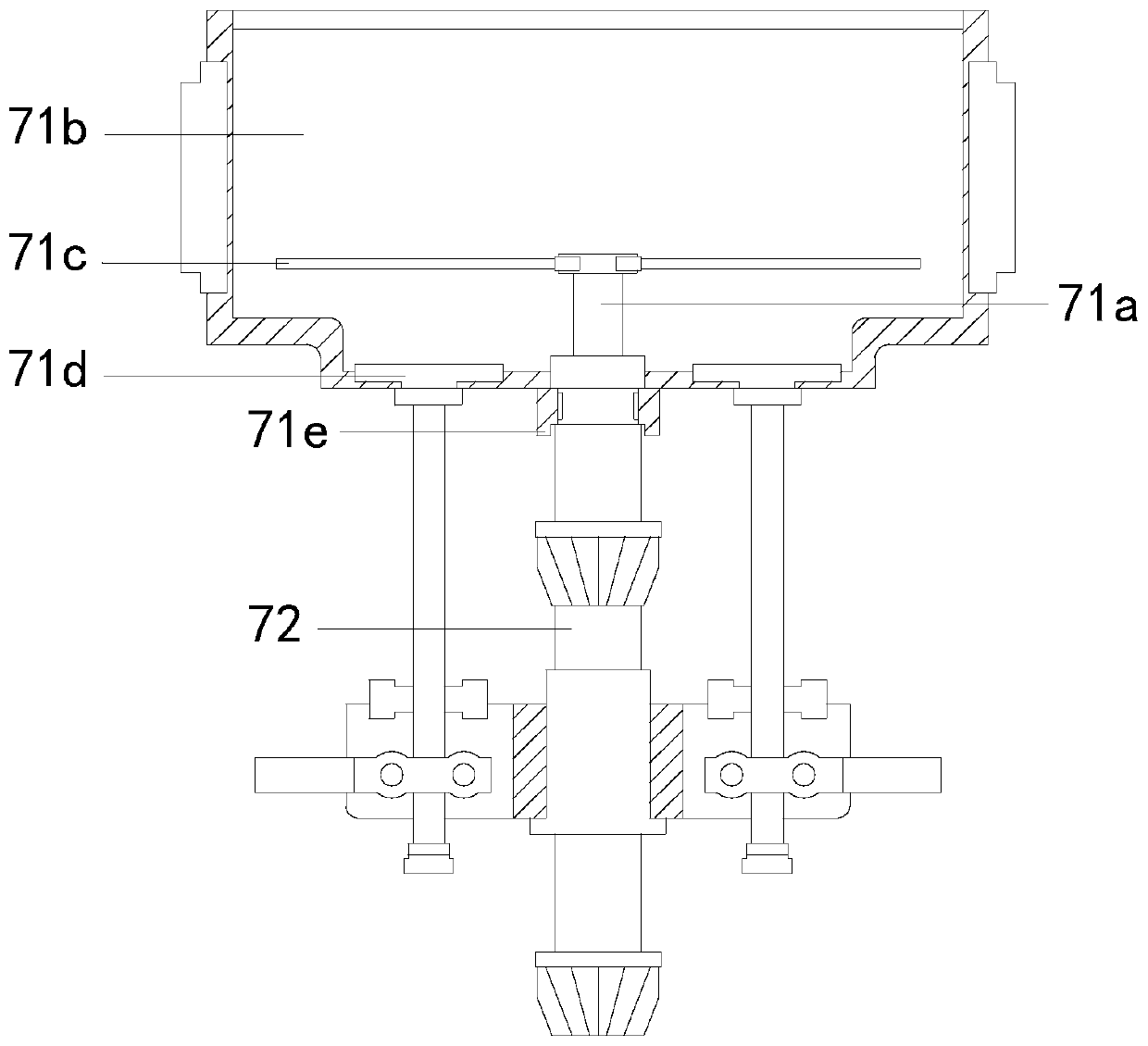

Agricultural ditching machine

ActiveCN111165099AImprove the propulsion structureImprove ditching efficiencySpadesPloughsAgricultural scienceAgricultural engineering

The present invention discloses an agricultural ditching machine. The agricultural ditching machine structurally comprises handles, an engine, a frame, hydraulic push rods, a wheel axle, roller wheelsand a ditching device. The agricultural ditching machine has the effects that a water injection mechanism, a transmission mechanism and a ditching mechanism arranged on the ditching device are mutually linked, and a torque generated by the engine is converted into rotation kinetic energy of the roller wheels, flow exhaust kinetic energy of a water tank and spiral propelling kinetic energy of a spiral ditching plow through the transmission mechanism, so that the energy consumption required for ditching by equipment can be reduced; and water flow is used to moisten hard soil, thereby improvingthe ditching efficiency of a propelling structure composed of the spiral ditching plow and the roller wheels on the hard soil, facilitating shaping of ditches and preventing generation of falling soil.

Owner:桐乡市高桥依田家庭农场

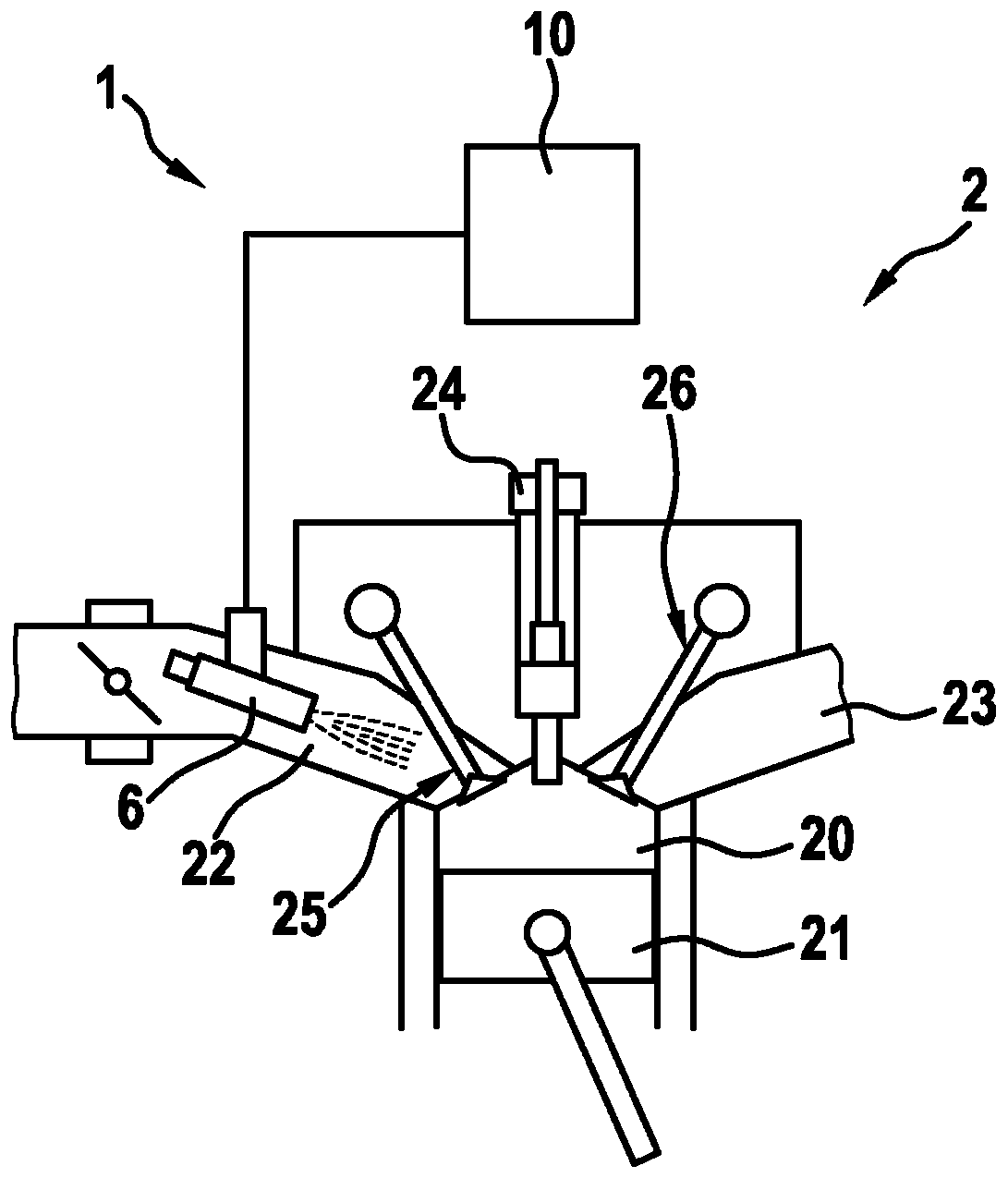

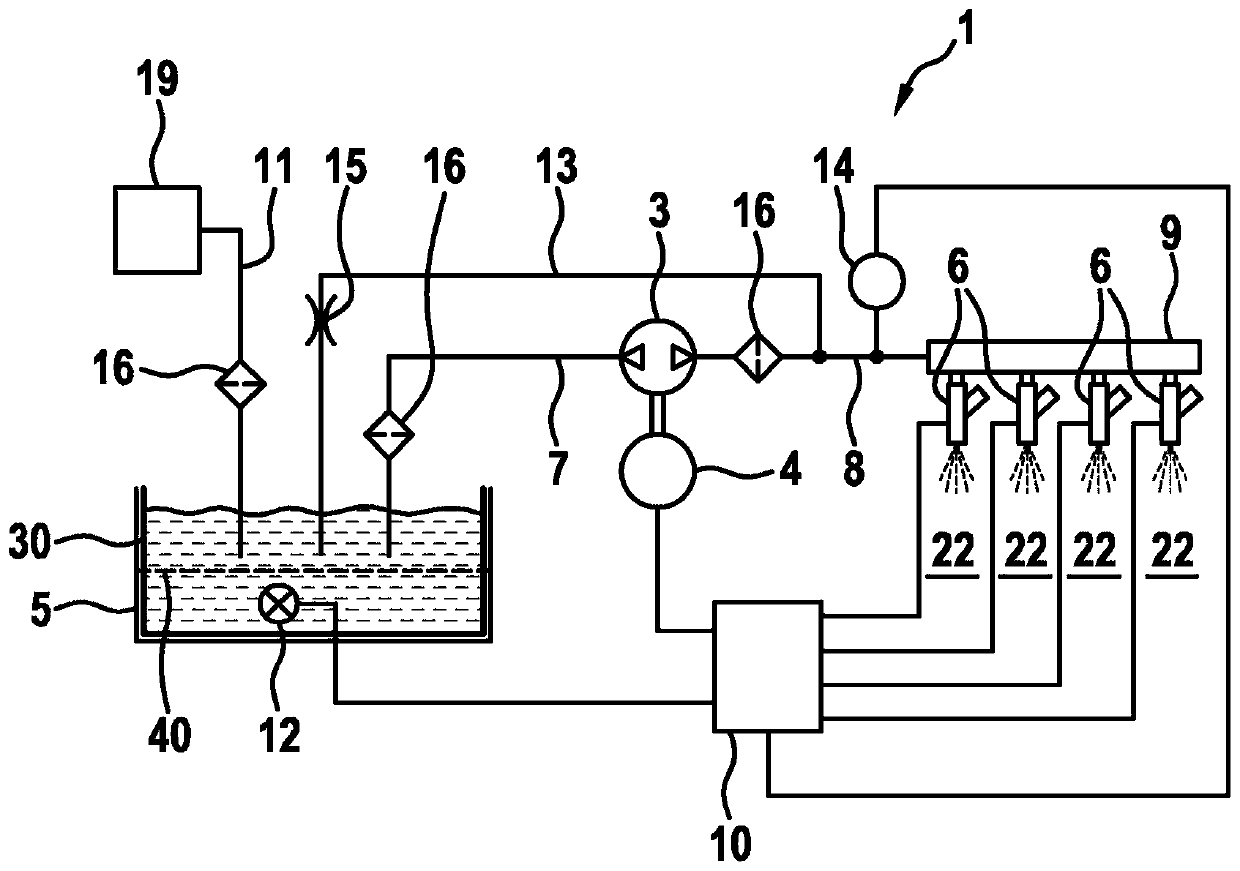

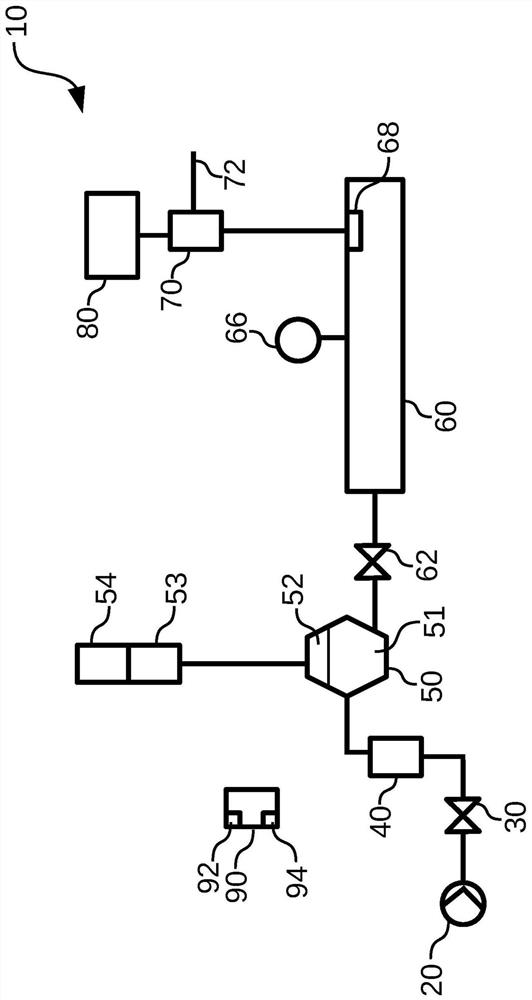

Water injection device and method of an internal combustion engine

InactiveCN111065812AGood and long-lasting protectionProtect fromNon-fuel substance addition to fuelInternal combustion piston enginesInternal combustion engineMechanics

The invention relates to a water injection device of an internal combustion engine (2), comprising at least one water tank (5) for storing water, at least one water injector (6) for injecting water, which water injector is connected to the water tank (5), and at least one conveying element (3) for conveying the water from the water tank (5) to the water injector (6), wherein, according to the invention, the device (1) comprises a metal that forms cationic acid, in particular silver, for decontaminating the water.

Owner:ROBERT BOSCH GMBH

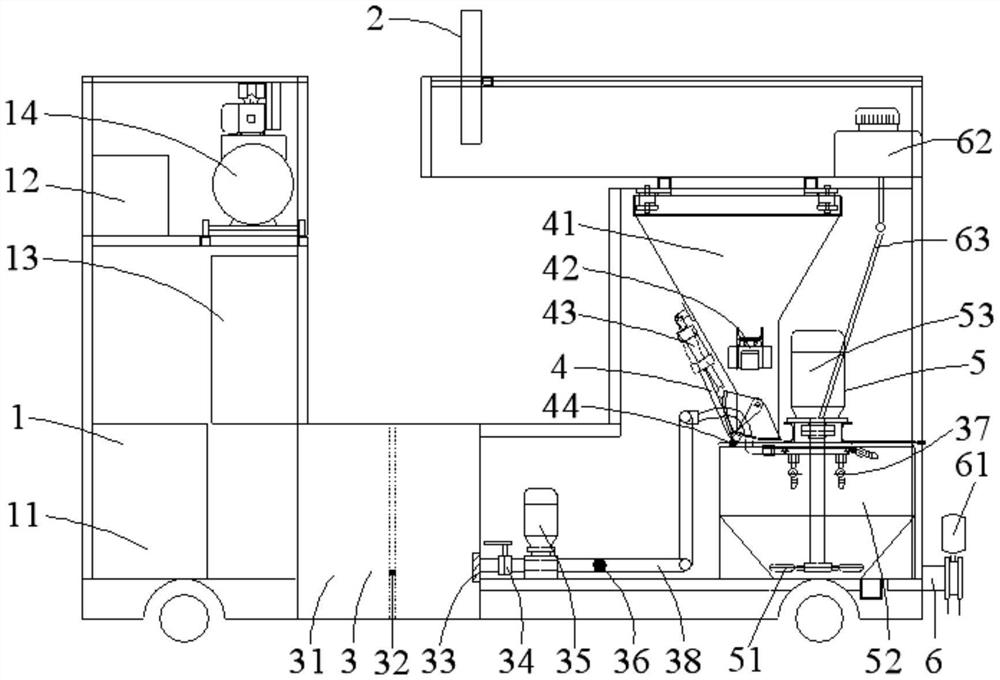

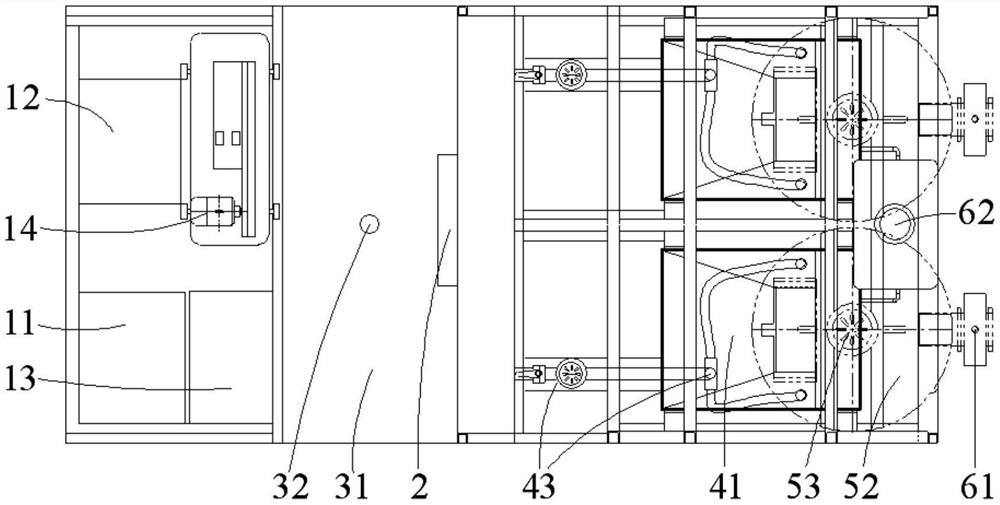

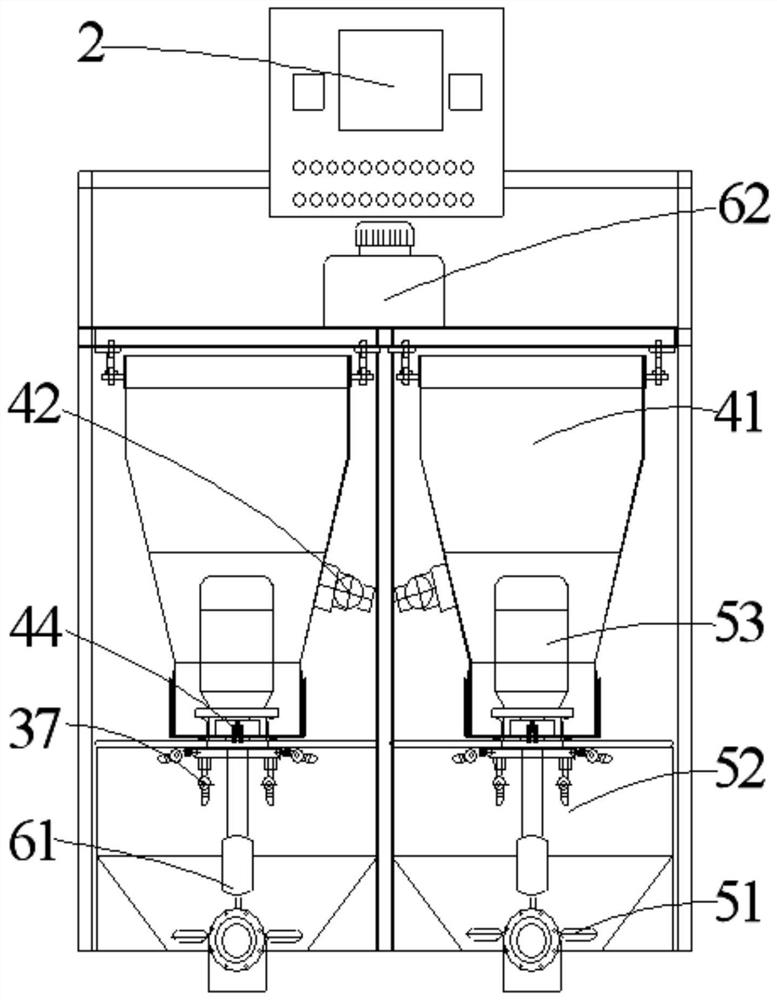

Movable pouring type composite concrete pavement grouting equipment

PendingCN113897840AReduce the problem of decreased mobilityReduce manual operationsHollow article cleaningRoads maintainenceSlurryRoad surface

The invention relates to movable pouring type composite concrete pavement grouting equipment which comprises a PLC electrical control system, a power system, an automatic water injection and cleaning system, a dry material weighing system, a mixing and stirring system and the like. The power system comprises an engine, a generator, an air compressor and the like; the automatic water injection and cleaning system comprises a water tank, a liquid level meter, a pipeline, a nozzle and the like; the dry material weighing system comprises a material bin, a vibration motor and a pneumatic controller; the mixing and stirring system comprises a stirring barrel, a stirring shaft and a motor; and the power system provides electric power and power, the automatic water injection and cleaning system adds water to and cleans the stirring barrel, and the mixing and stirring system stirs water and concrete slurry. According to the invention, on-site mixing and grouting are realized, fluidity reduction caused in the transportation process can be reduced, and the grouting quality is improved. In the grouting process, the pressure of a grout outlet nozzle can be adjusted through a pneumatic pressure increasing valve, the grouting depth is increased, the working efficiency is improved, later manual operation is reduced, and the cost is reduced.

Owner:北方道路科技(辽宁)有限公司

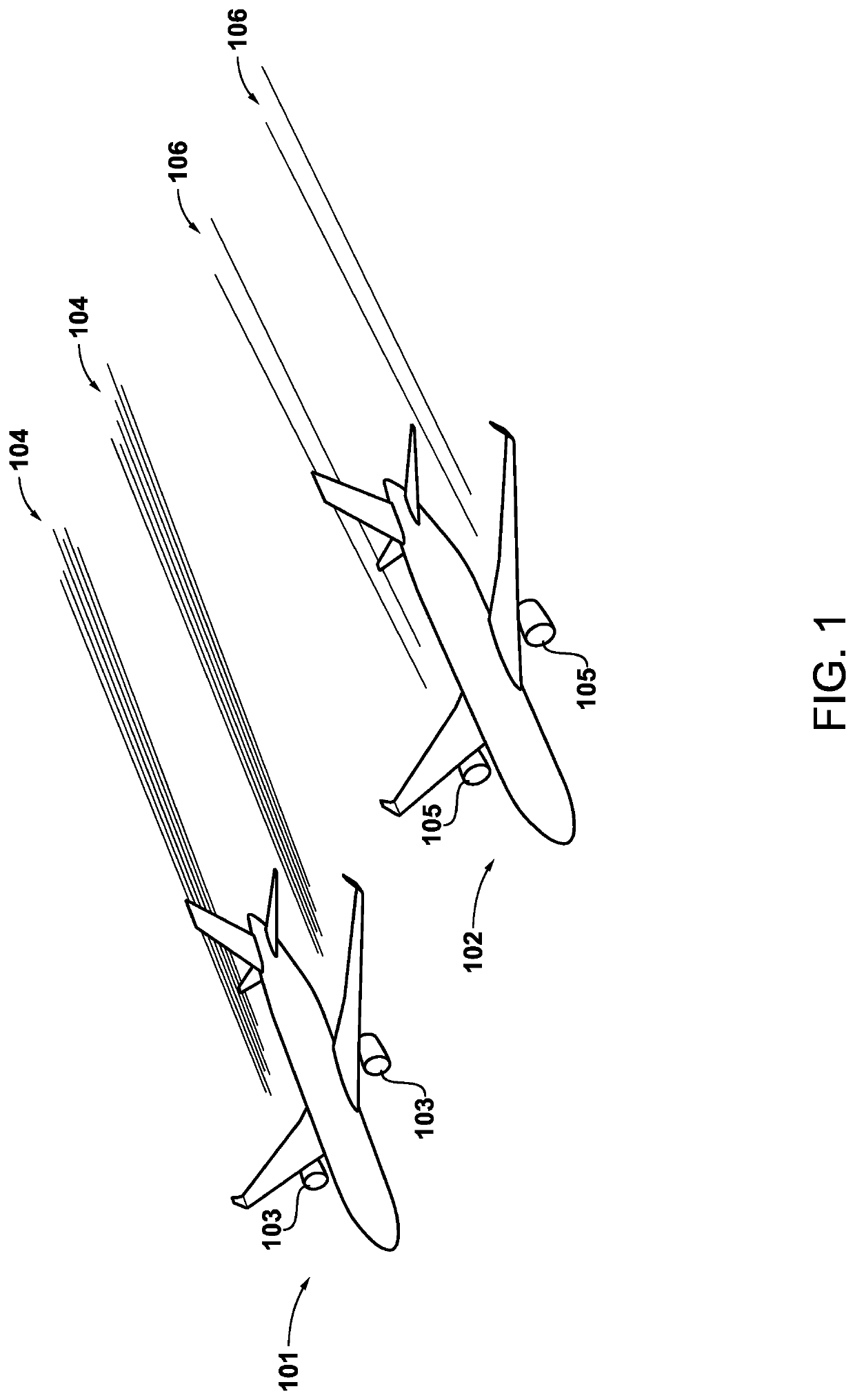

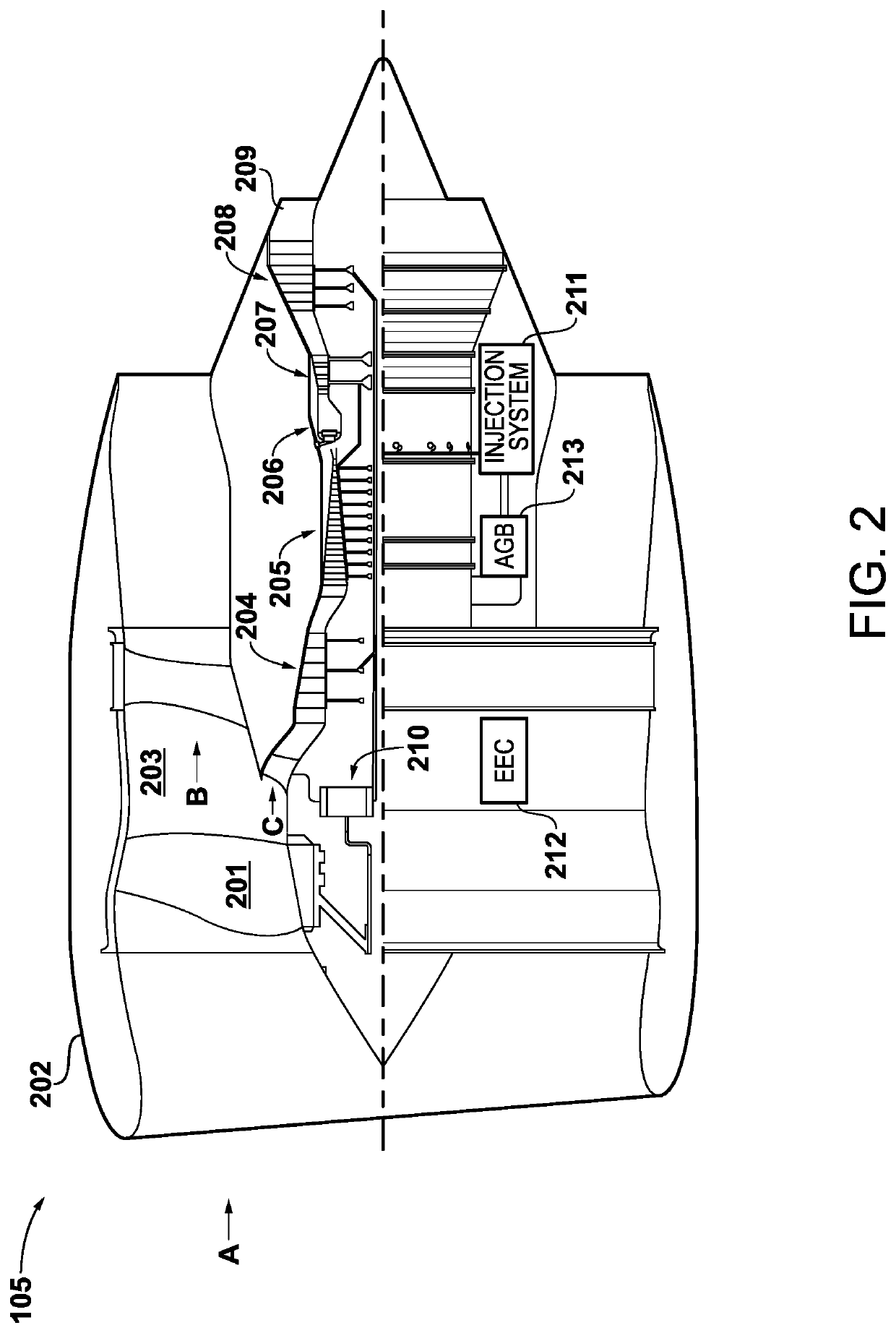

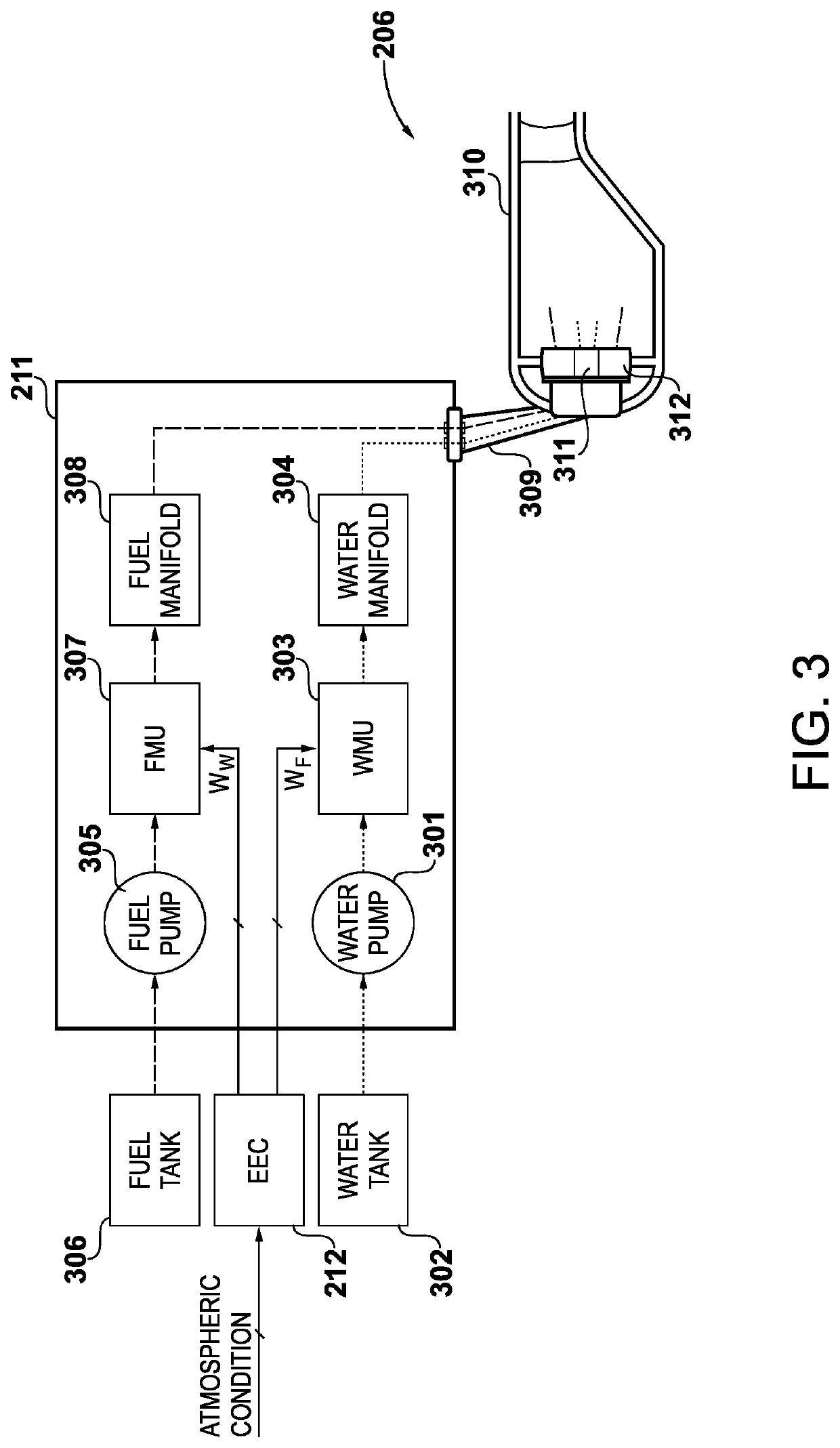

Water injection

ActiveUS20210277839A1Emission controlContinuous combustion chamberGas turbine plantsCombustorControl system

A gas turbine engine for an aircraft. The gas turbine comprises a combustor, a fuel injection system connected with a source of fuel and configured to inject fuel into the combustor, a water injection system connected with a source of water and which is configured to inject water into the combustor, and a control system. The control system is configured to identify an atmospheric condition; determine a water-fuel ratio for injection into the combustor of the gas turbine engine in response to the atmospheric condition; and control injection of fuel and water by the fuel injection system and the water injection system according to said water-fuel ratio to control an soot emissions caused by combustion of fuel therein.

Owner:ROLLS ROYCE PLC

Method for determining an air mass and direct water injection system

PendingCN113795663AReduce manufacturing costSure easyElectrical controlNon-fuel substance addition to fuelCombustion chamberEnvironmental engineering

Owner:BAYERISCHE MOTOREN WERKE AG

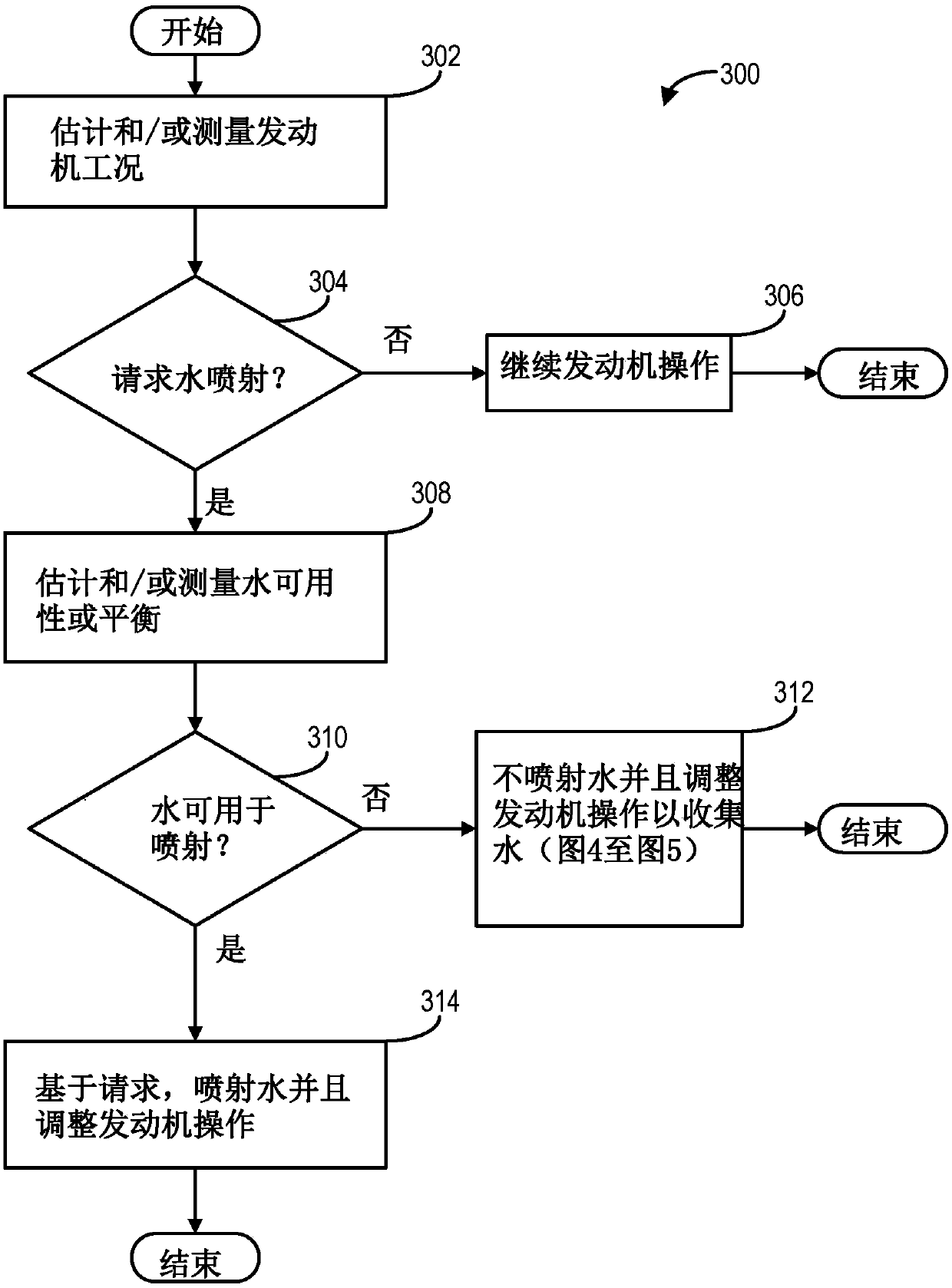

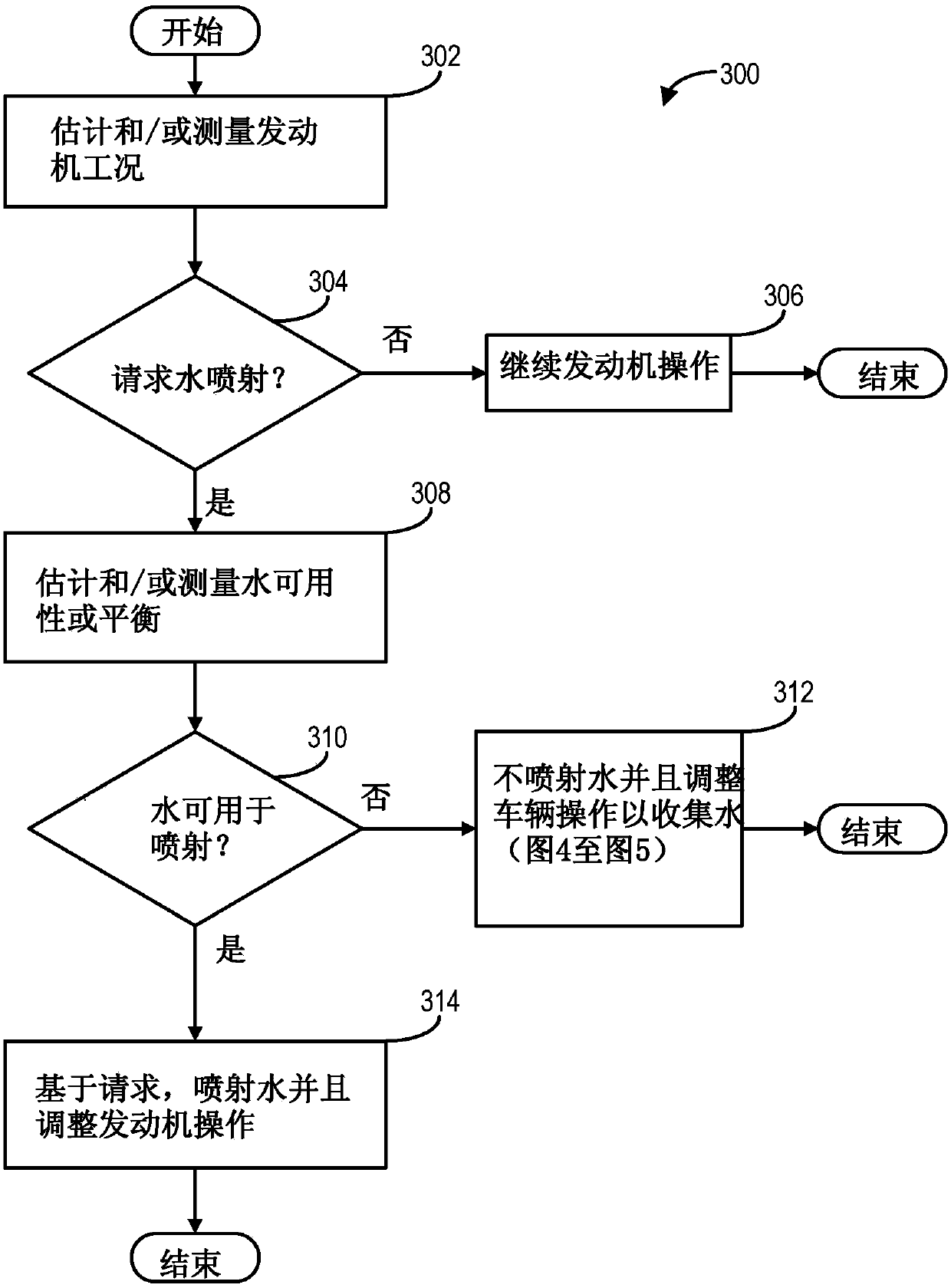

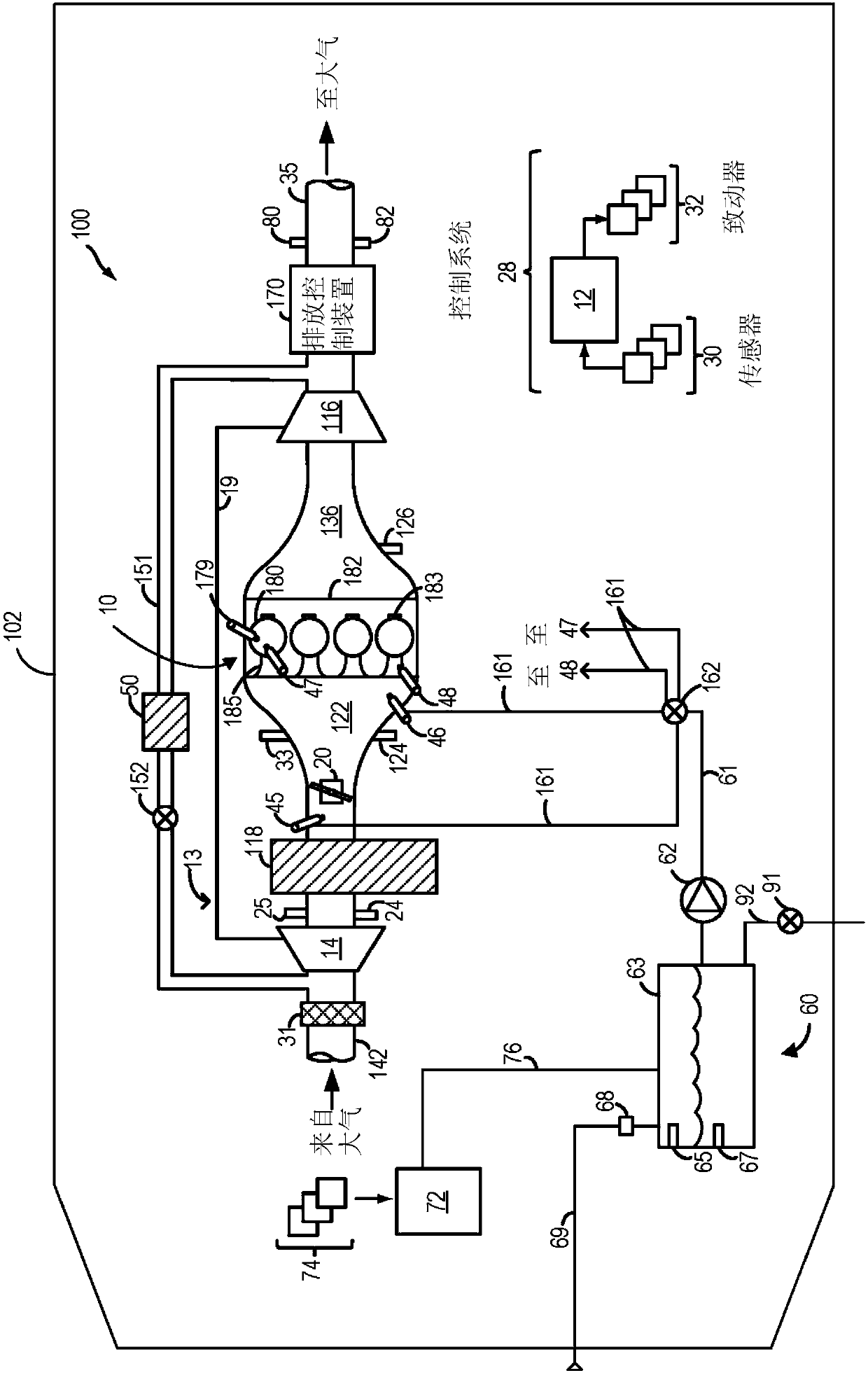

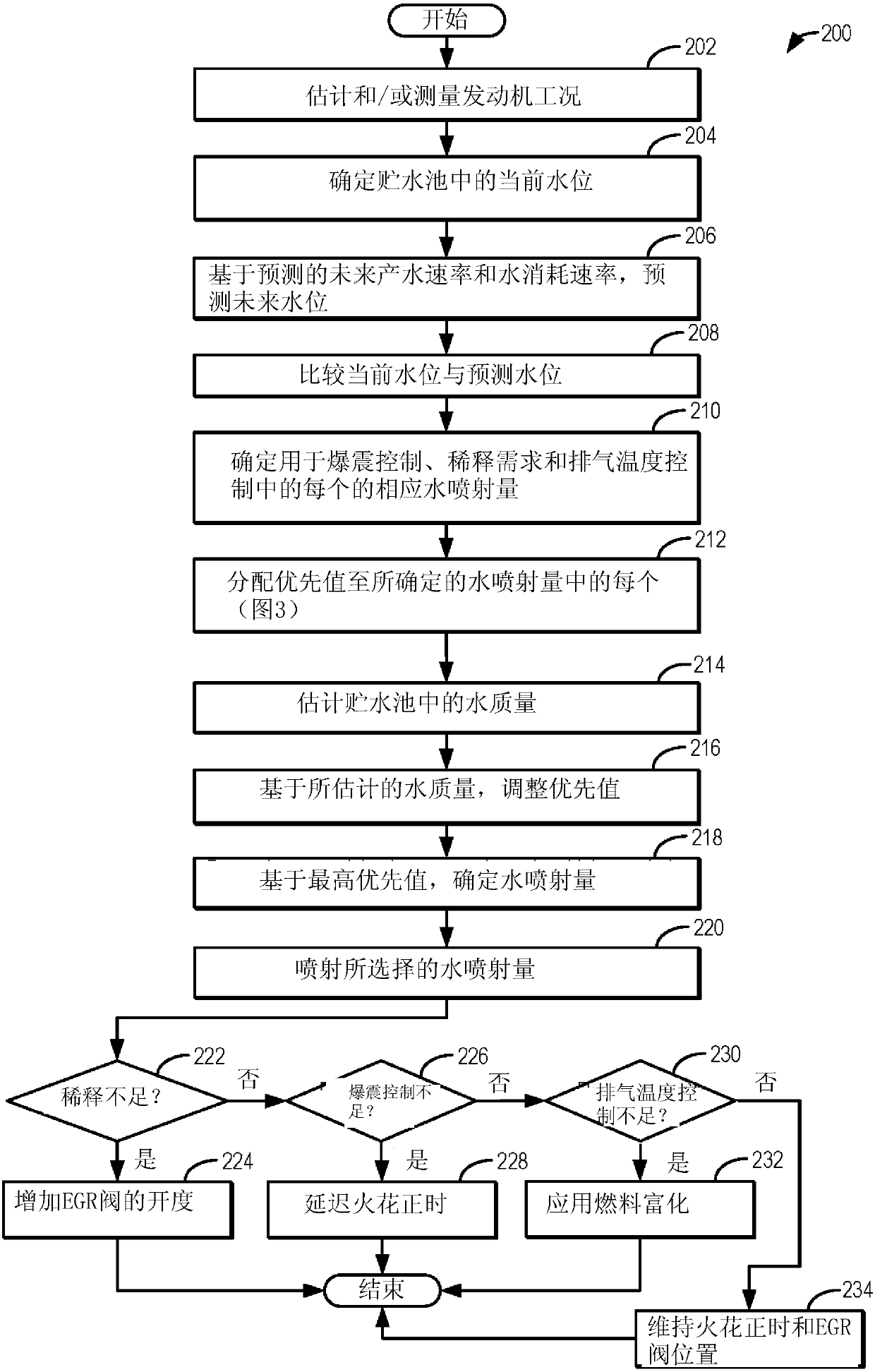

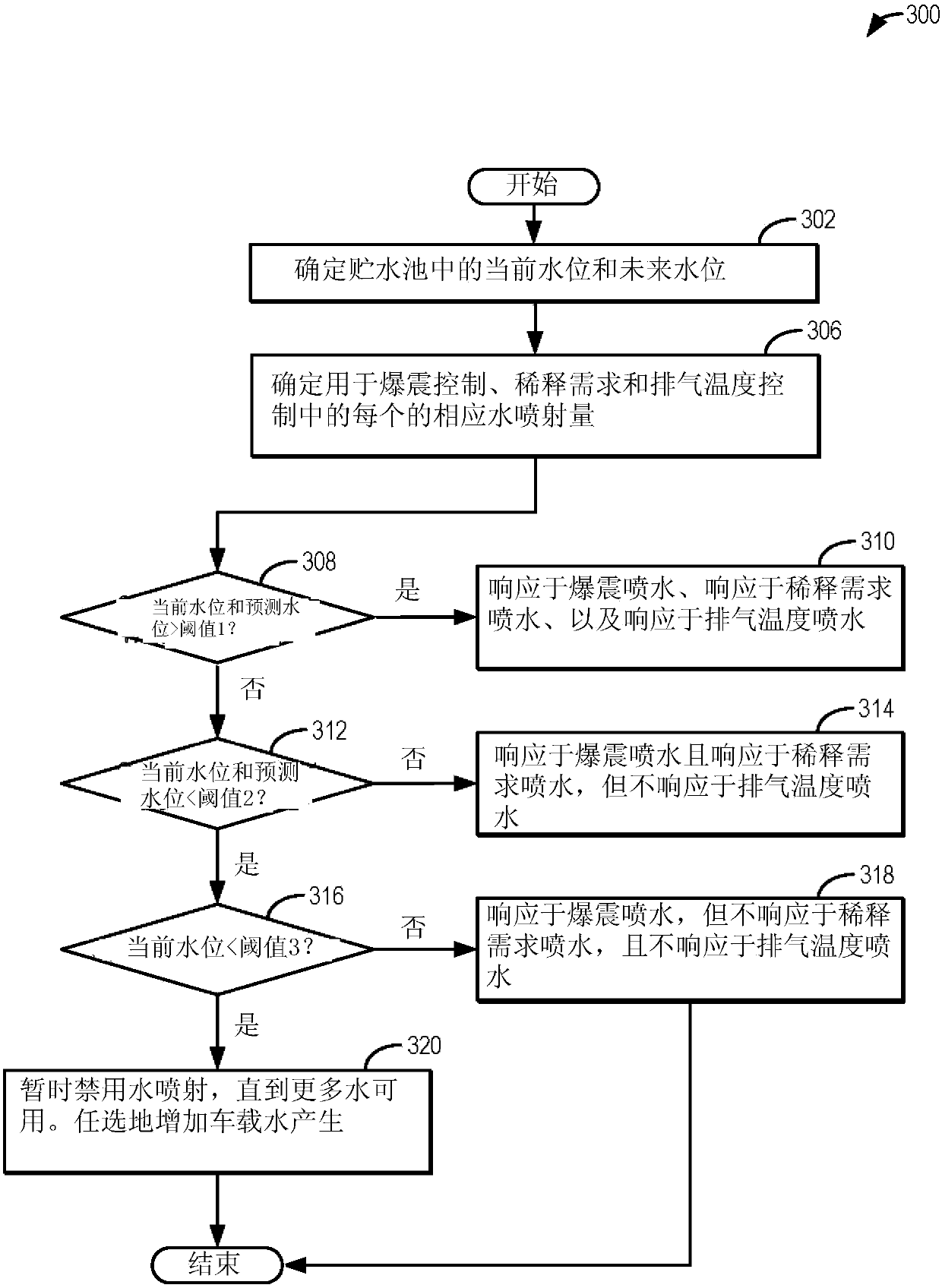

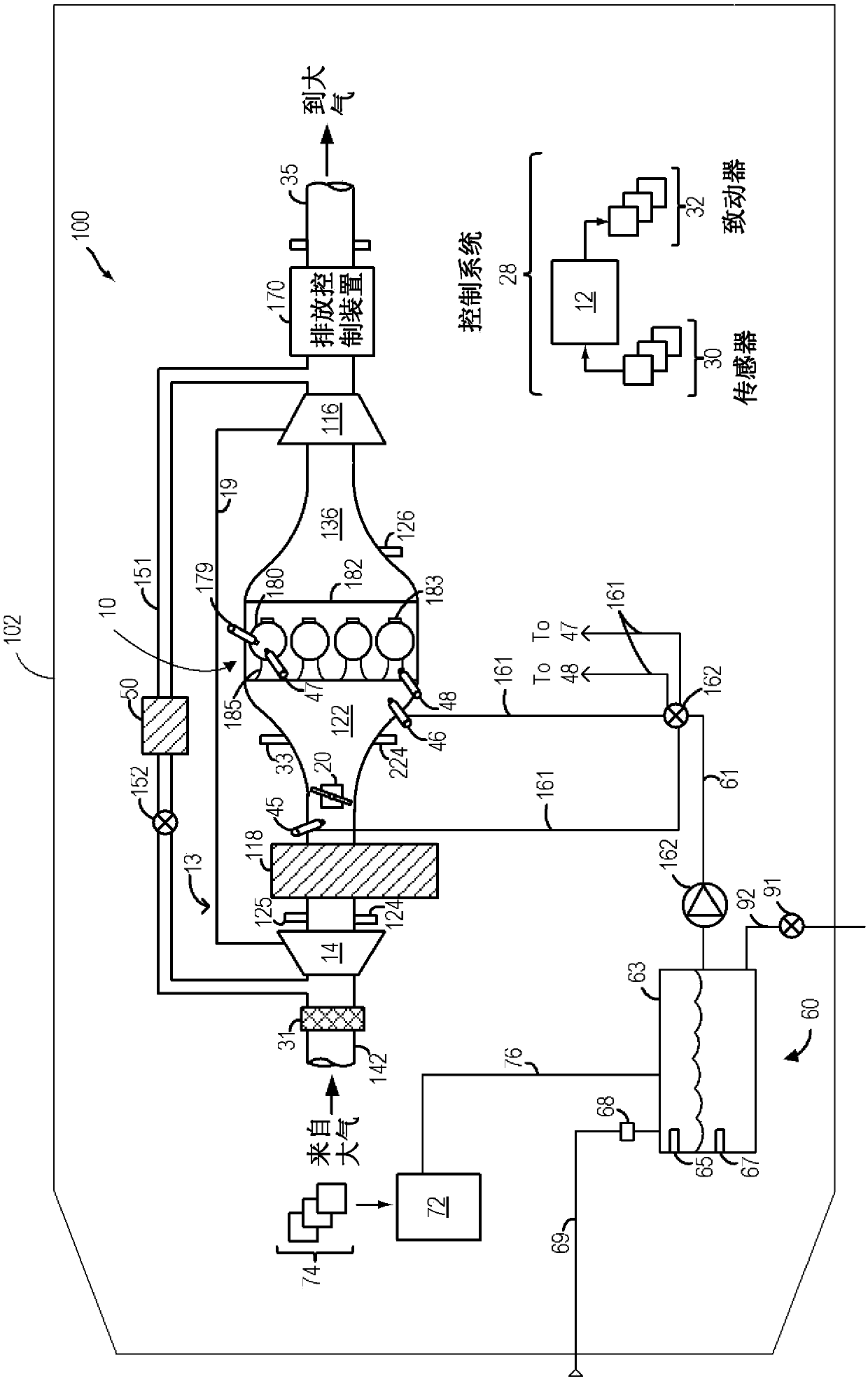

Method and system for controlling water injection

ActiveCN107893713AElectrical controlNon-fuel substance addition to fuelEnvironmental engineeringWater injection (engine)

The application provides a method and a system for controlling water injection. Methods are provided for optimizing usage of water from a water injection system that injects water into the engine responsive to engine operating conditions such as knock, exhaust temperature, and dilution demand. An amount of water selected for injection purposes, as well as an order of water injection responsive tothe various engine operating conditions, is varied based on a current water level relative to a predicted future water level. The method allows water usage benefits to be maximized particularly when water availability is limited.

Owner:FORD GLOBAL TECH LLC

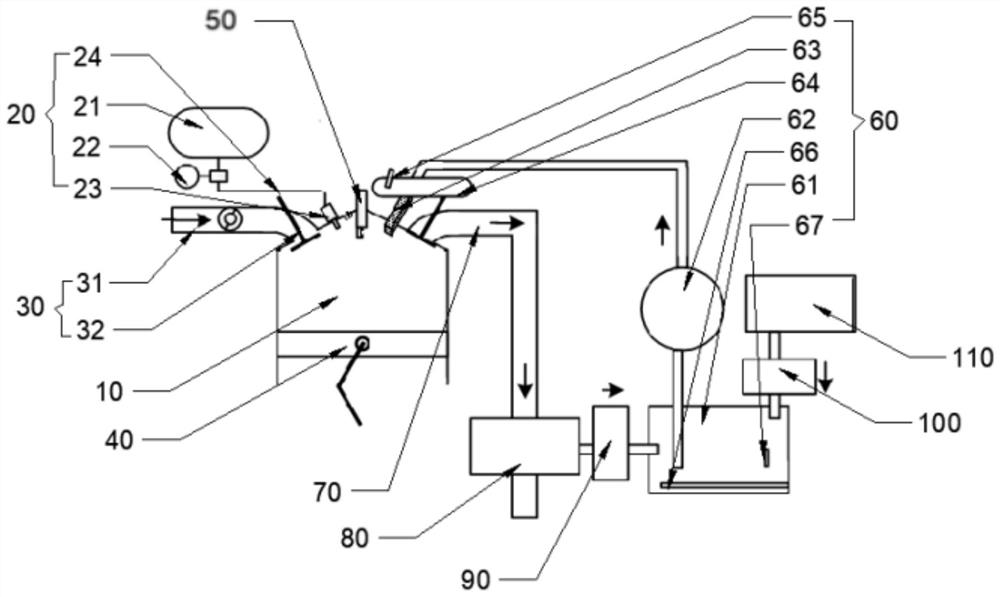

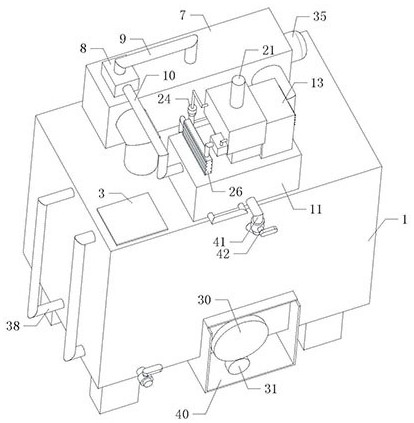

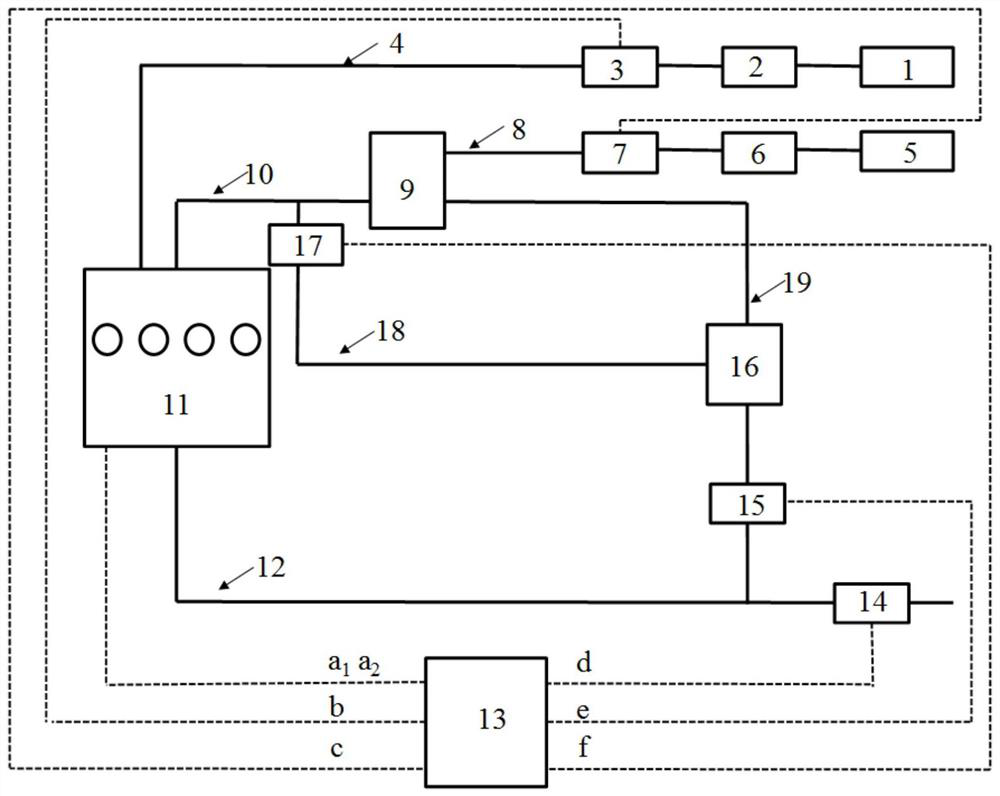

A zero-nitrogen engine and its control method based on water injection to control pressure rise rate and oxygen closed-loop cycle

ActiveCN109707505BImprove stabilityAchieve recyclingElectrical controlNon-fuel substance addition to fuelPressure riseNitrogen gas

The invention relates to an oxygen closed-loop circulation zero-nitrogen engine for controlling the pressure rise rate based on water spraying, and a control method thereof. Serving an engine rotationspeed signal (a1) and an engine pressure rise rate signal (a2) as the control basis, a control unit (13) controls a first valve (14), a second valve (15), a hydrogen flow controller (3), an oxygen flow controller (7) and a water spraying device (17) after the engine reaches the idle speed, recycling of oxidizing agents in tail gas of the engine and control over the combustion pressure rise rate inside a cylinder are achieved, and the utilization rate, heat efficiency and combustion stability of the oxidizing agents of the engine are effectively improved. As the clean oxidizing agents are adopted, the defect that nitrogen generates NOx in a high-temperature environment in a cylinder during air intake of a traditional hydrogen engine is overcome, and zero emission of the engine is achieved.

Owner:BEIJING UNIV OF TECH

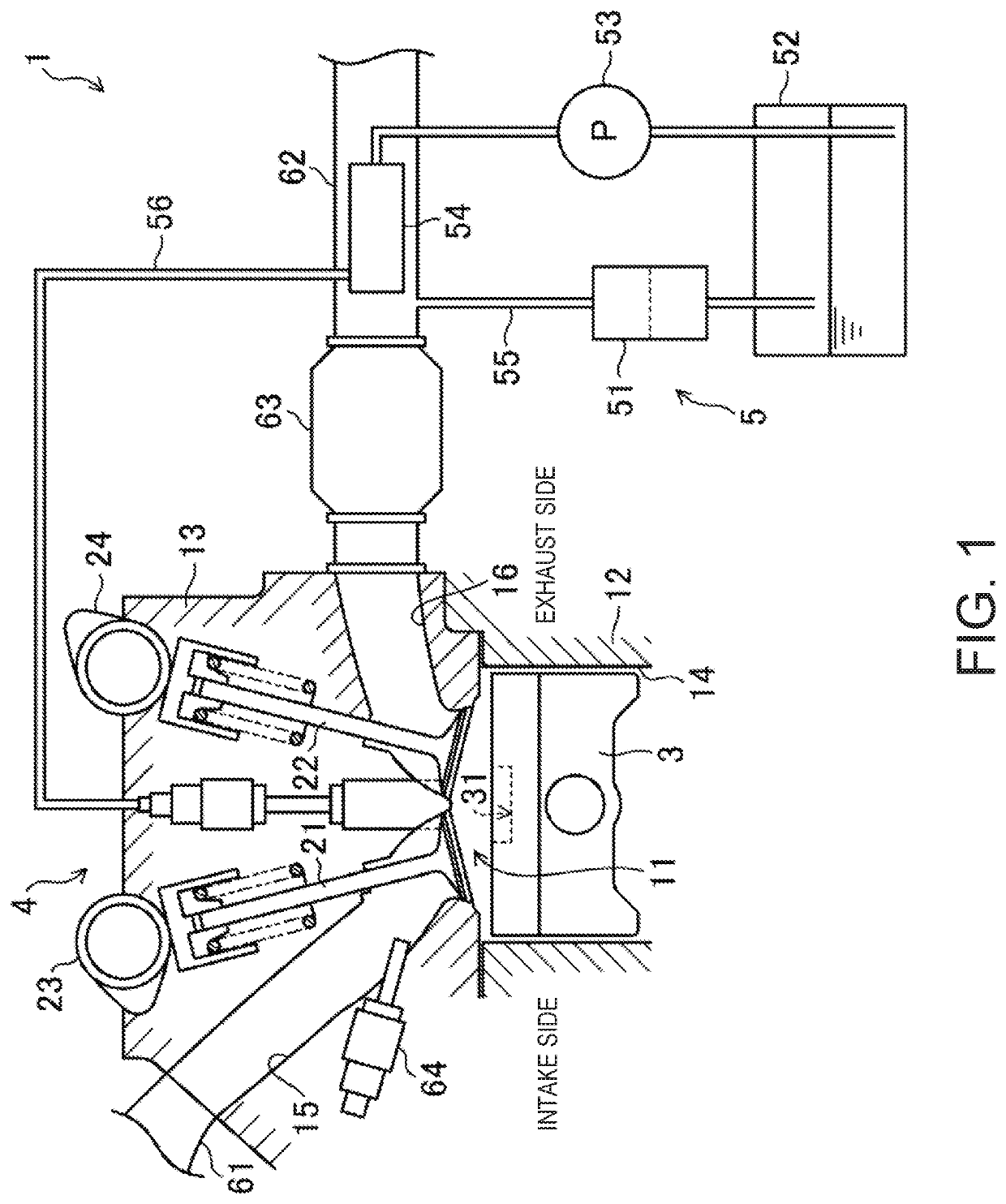

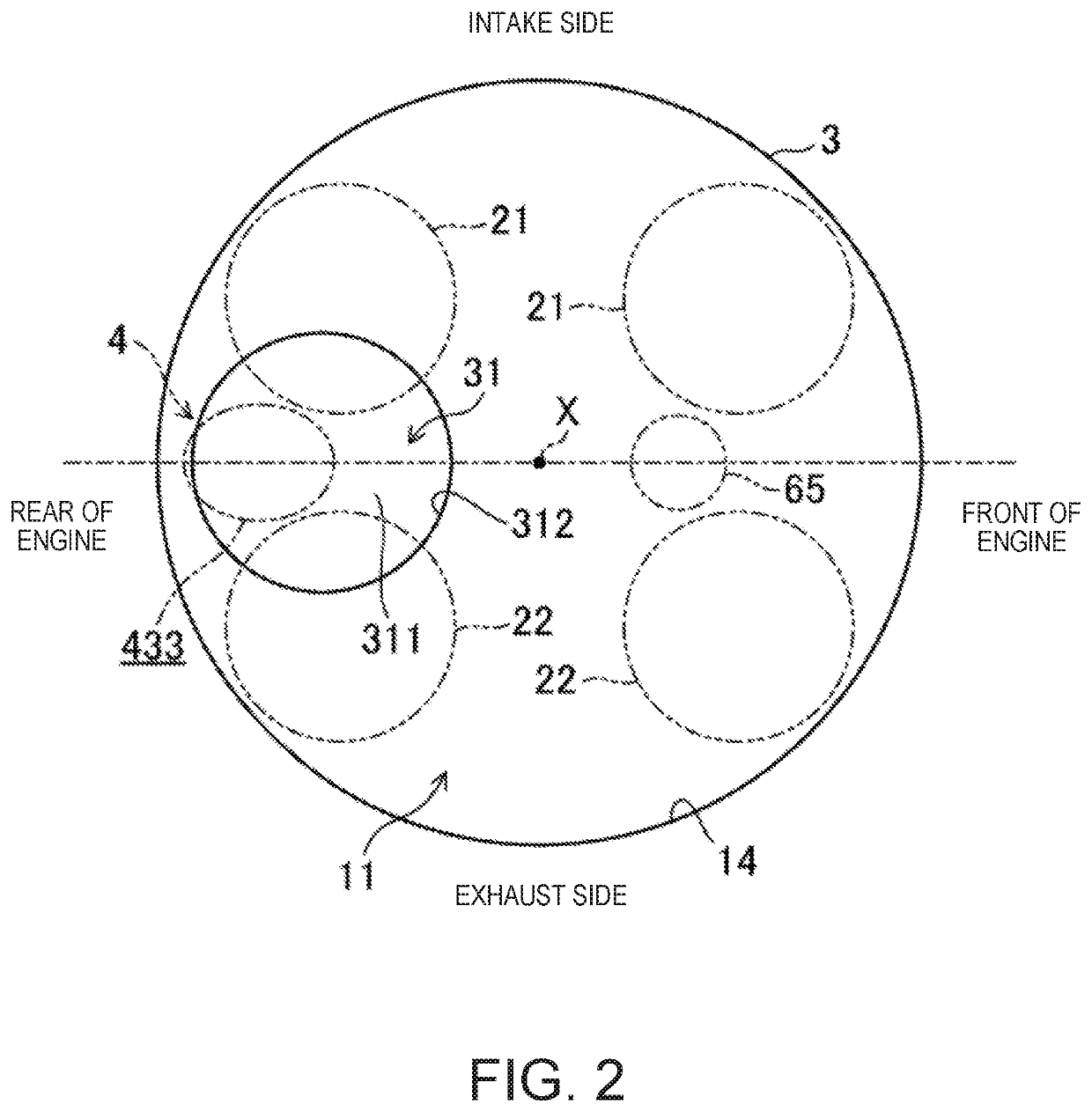

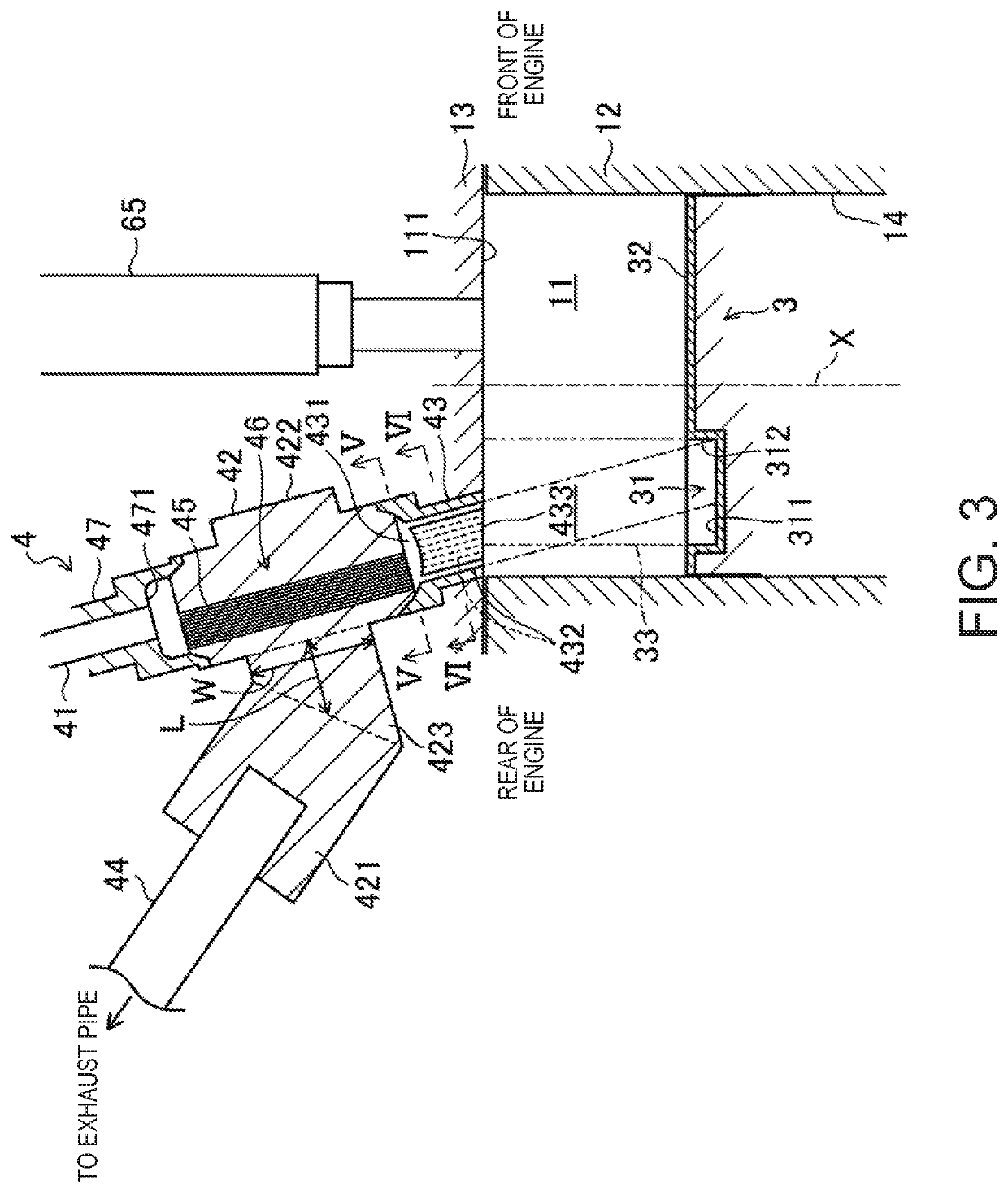

Combustion chamber structure of engine

ActiveUS20210010413A1Reduce diffuseStable ignitionInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberReciprocating motion

An engine system includes a combustion chamber including a cylinder formed in an engine and a piston configured to reciprocate inside the cylinder, a spark plug disposed in a ceiling part of the combustion chamber, and a water injection device configured to inject water into the combustion chamber through a plurality of nozzle holes facing the inside of the combustion chamber. The piston has a cavity in an upper surface thereof. The water injection device injects water into the cavity in a compression stroke at a timing when an extension of axes of at least some of the nozzle holes intersects the cavity. The cavity has a bottom part where the water injected by the water injection device collides, and a raising part configured to raise the water spreading along the bottom part toward the water injection device.

Owner:MAZDA MOTOR CORP

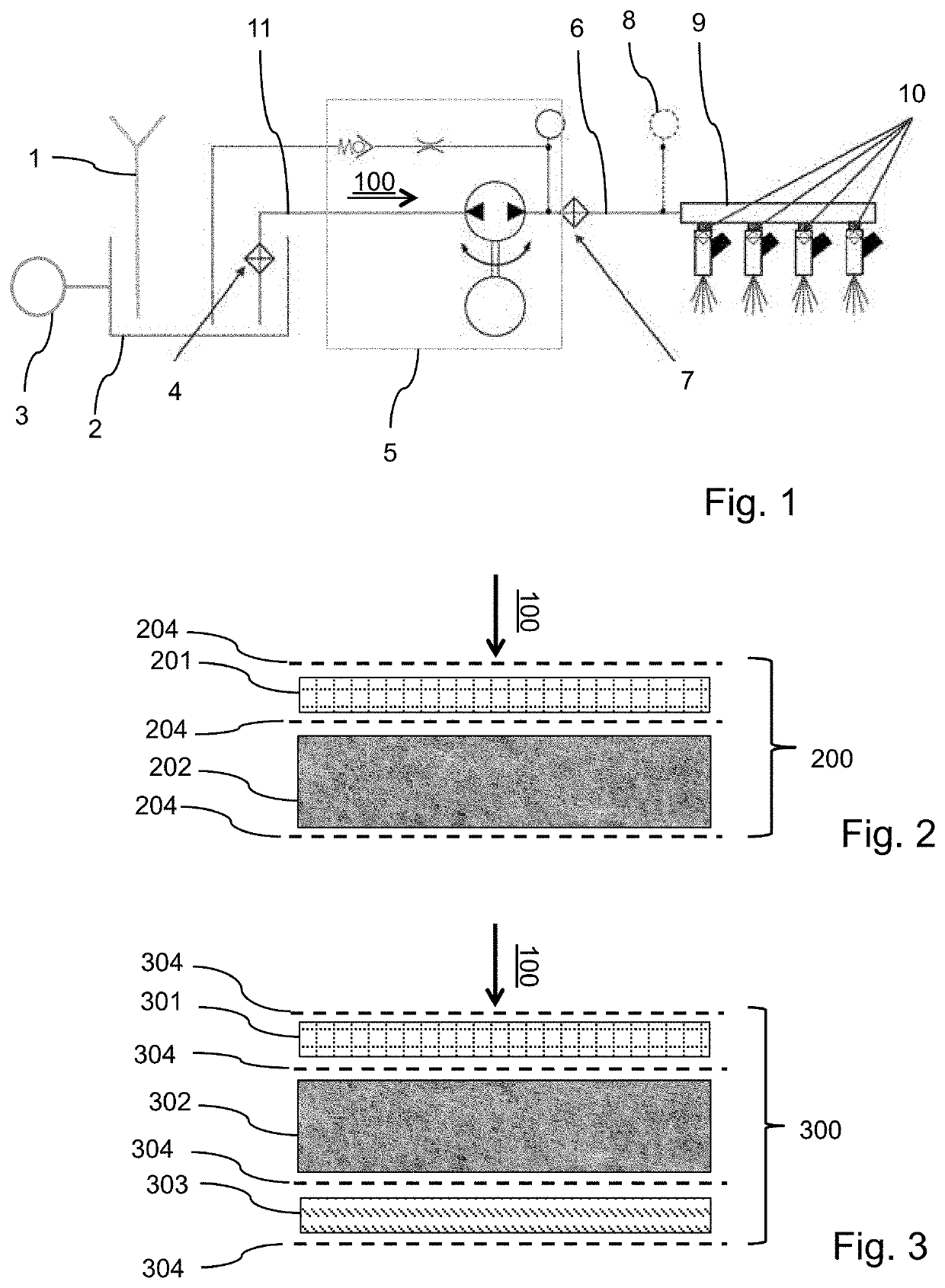

Filter Medium and Production Method, Filter Element, Use of the Filter Element, and Water Injection System

InactiveUS20200217275A1Satisfied with the resultMeet growth requirementsBiocideNon-fuel substance addition to fuelActive agentPhysical chemistry

A filter medium is provided with a first layer as a support layer and a second layer as a filtration layer arranged downstream of the first layer. The first layer and the second layer both are provided with at least one active agent that is at least antibacterial. The active agent can be applied as a coating or as an impregnation. Examples of active agents are pyrithione, a metal salt of pyrithione, a pyrithione derivative, a metal salt of a pyrithione derivative, and a quaternary ammonium salt. A filter element is provided with such a filter medium in the form of a filter media pack. The filter medium and filter element can be used in a water injection system for internal combustion engines.

Owner:MANN HUMMEL GMBH

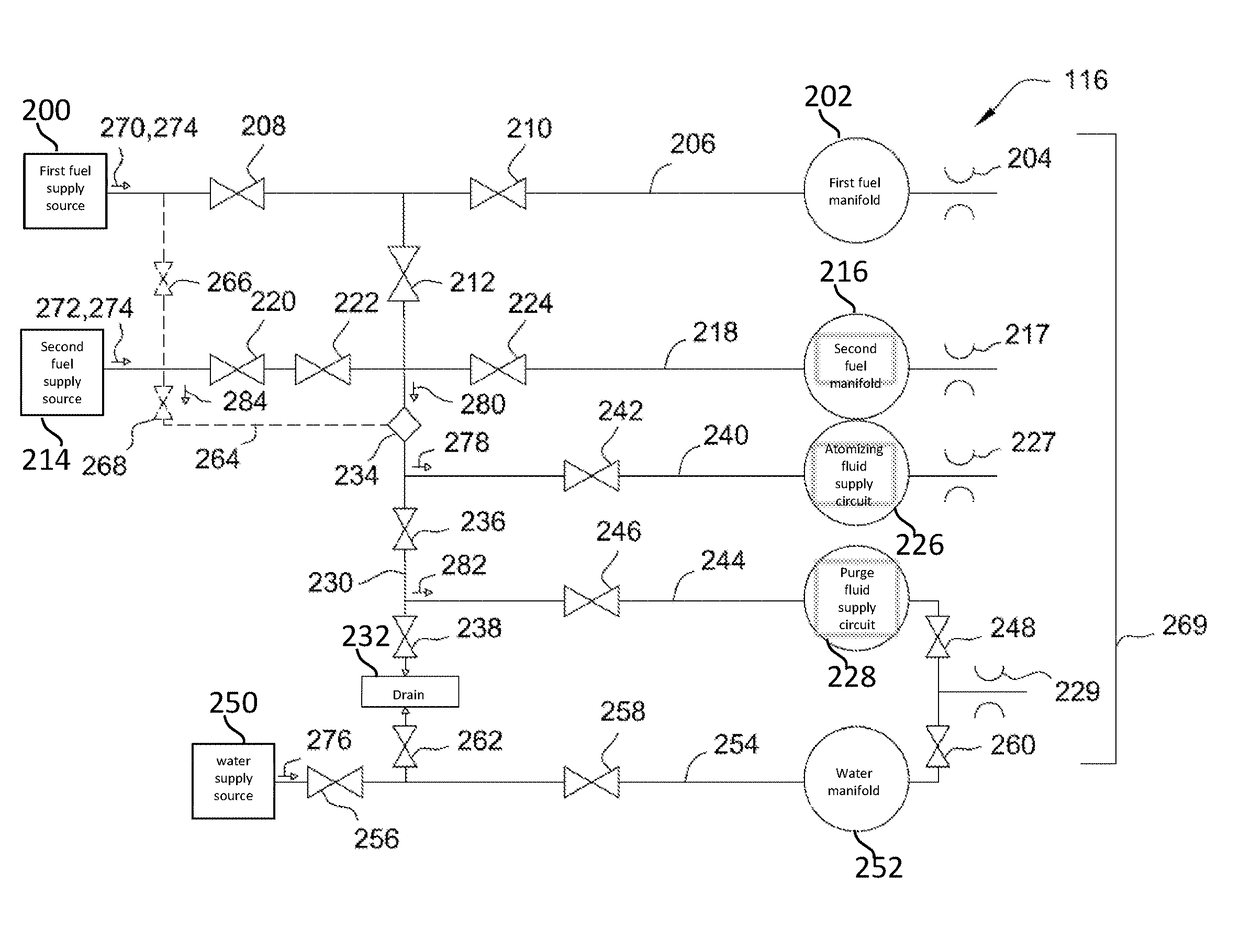

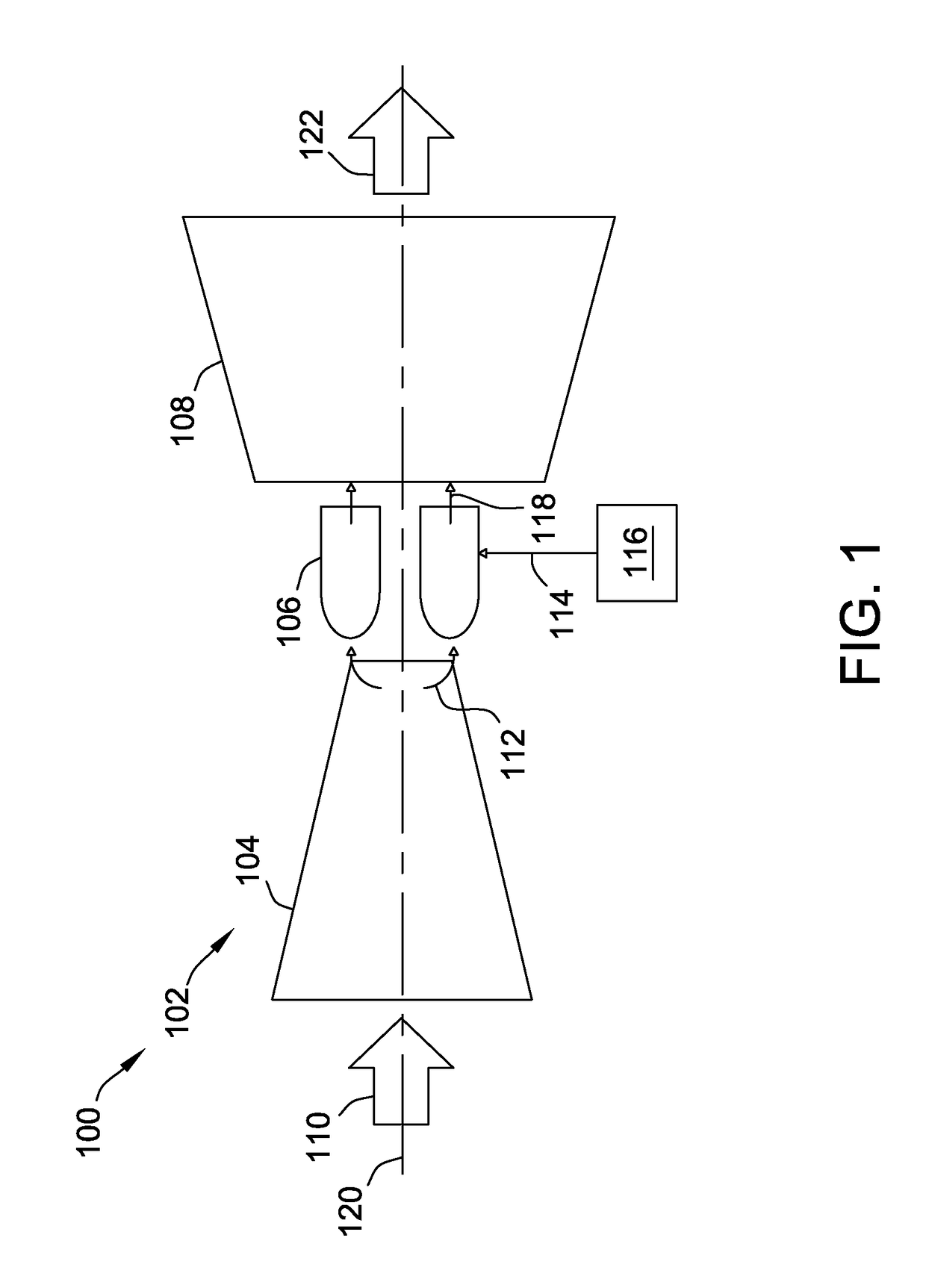

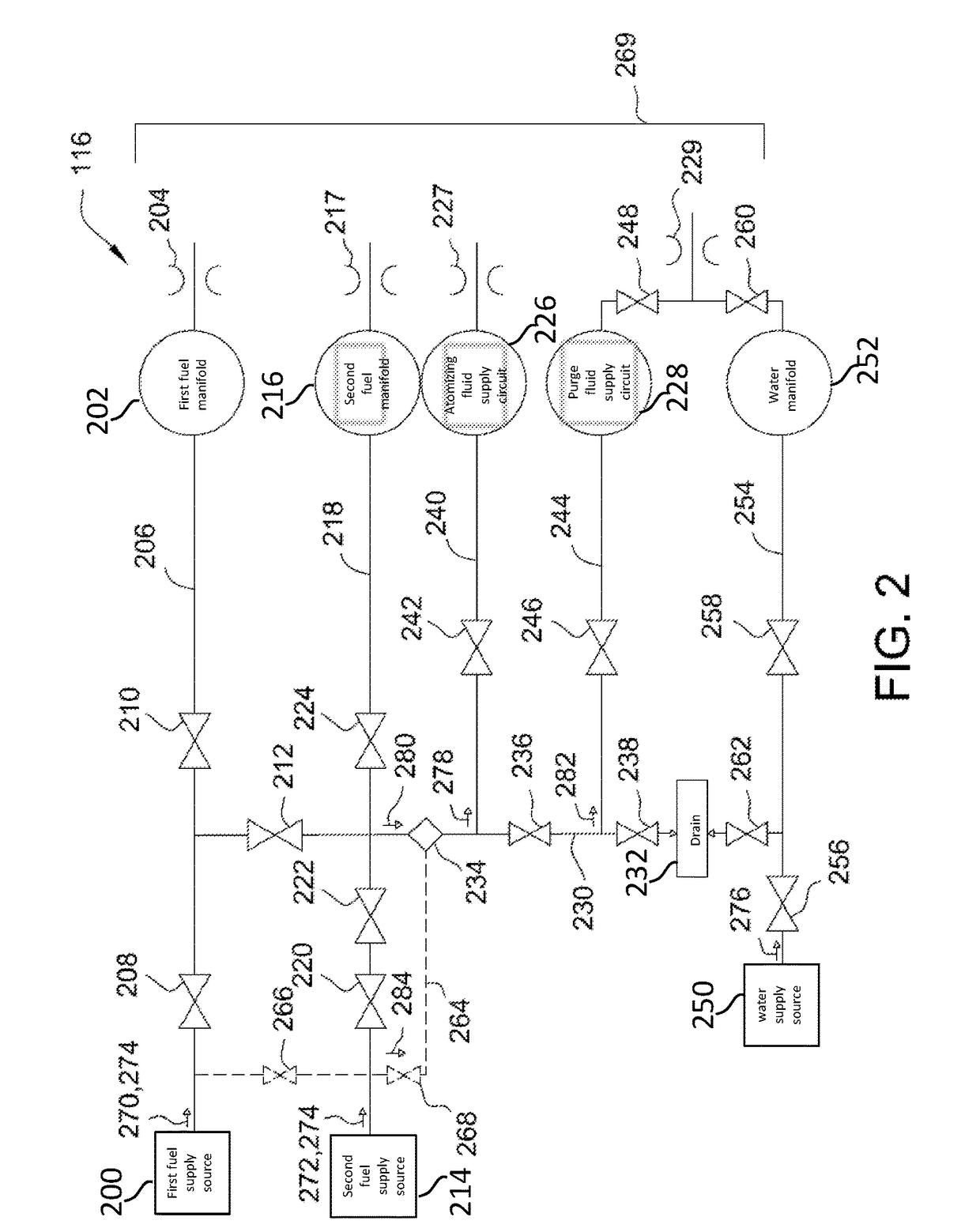

Fuel supply system for turbine engines and methods of assembling same

A fuel supply system includes a first fuel supply line coupled in flow communication with a first fuel nozzle and configured to channel a first fuel flow to the first nozzle. A second fuel supply line coupled in flow communication with a second fuel nozzle and configured to channel a second fuel flow to the second nozzle. A water supply line coupled in flow communication with a water injection nozzle and configured to channel a water flow to the water injection nozzle. An atomizing fluid supply circuit coupled in flow communication with the first and second fuel supply lines. The atomizing fluid supply circuit configured to channel an atomizing fluid flow to an atomizing nozzle and into atomizing contact with the water flow. The atomizing fluid includes a portion of at least one of the first fuel flow and the second fuel flow.

Owner:GE INFRASTRUCTURE TECH INT LLC

Vehicle-mounted exhaust gas diesel oil reformer capable of preventing thermal oxidation coking problem

ActiveCN111677602AReduce oxygen contentReduces potential for thermal oxidation cokingInternal combustion piston enginesFuel supply apparatusIn vehicleFuel tank

The invention discloses a vehicle-mounted exhaust gas diesel oil reformer capable of preventing a thermal oxidation coking problem. The vehicle-mounted exhaust gas diesel oil reformer capable of preventing the thermal oxidation coking problem comprises an engine cylinder, a diesel engine after-treatment device, an OSC deoxidization device, a reforming water tank, a reformer, a reforming oil tank and a gas return pipe; an exhaust manifold is wound around the reformer; the diesel engine after-treatment device is connected with the OSC deoxidization device and the exhaust manifold; one outlet ofthe OSC deoxidization device is connected with a cooling pipeline in the reforming water tank; the other end of the cooling pipeline in the reforming water tank is connected with the reforming oil tank; the reforming water tank is connected to the reformer through a water injection pump; the reforming oil tank is connected with the reformer through the gas return pipe; an outlet of the reformer iscorrespondingly connected to the gas return pipe and the OSC deoxidization device; and the other end of the gas return pipe is connected with a gas intake branch. After engine after-treatment exhaustgas is deoxidized and cooled, dissolved oxygen in a fuel is replaced with cooled and deoxidized exhaust gas; and by constructing an oxygen-free reforming environment, the thermal oxidation coking problem in the fuel reforming reaction process is improved.

Owner:TIANJIN UNIV

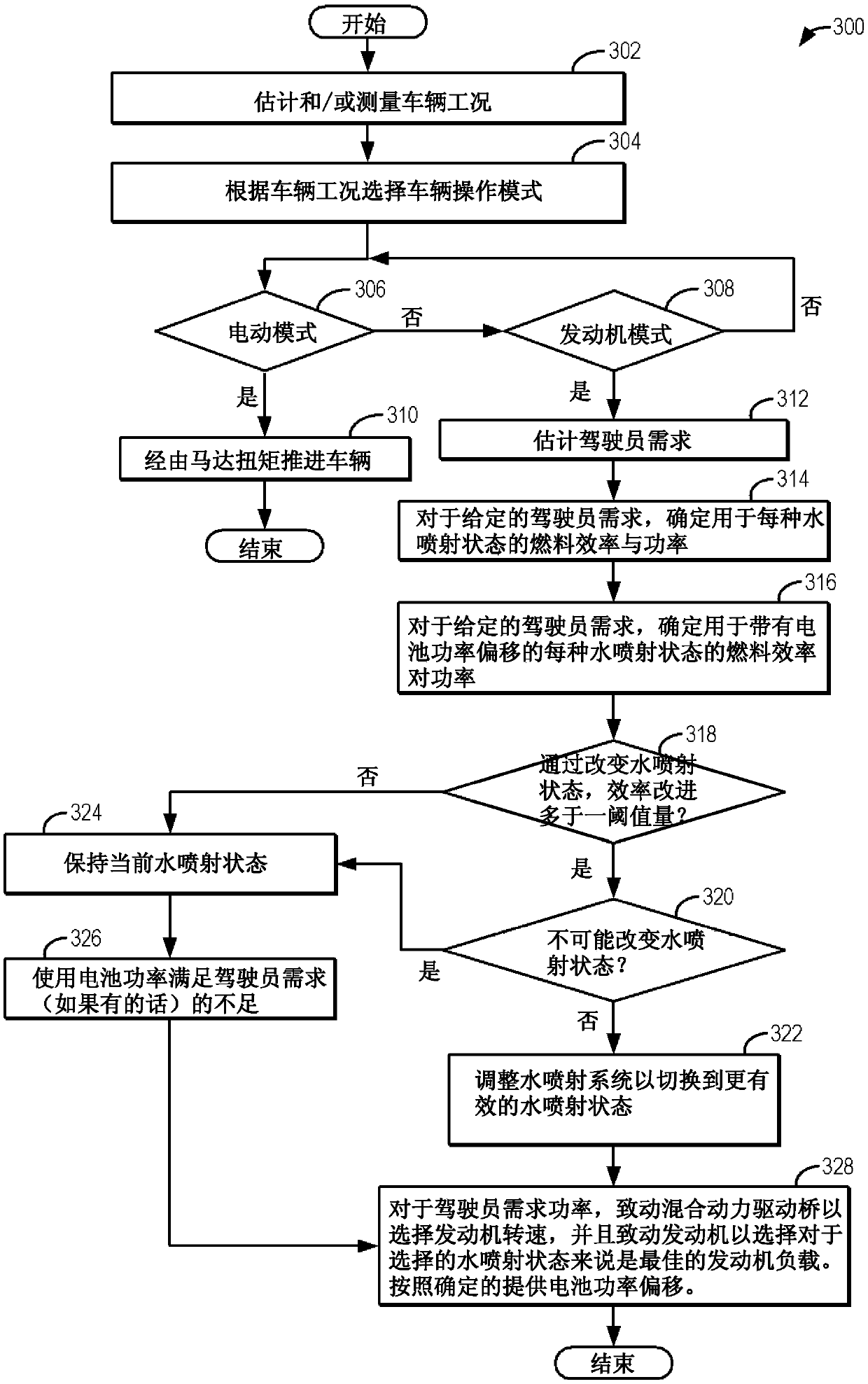

Method and system for controlling water injection

ActiveCN107642421AImprove economyReduced knock limitHybrid vehiclesElectrical controlEngine efficiencyEngineering

The invention discloses a method and system for controlling water injection. Methods and systems are provided for synergizing the benefits of engine water injection in a hybrid vehicle system. Duringengine operation, in response to a change in a driver demand, the controller may opt to switch between water injection states while using stored power assist. The selection may be based on the combination of water injection and stored power offset that provides the highest engine efficiency.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com