Method for determining an air mass and direct water injection system

A technology of air quality and injection system, applied in the direction of charging system, fuel injection control, electrical control, etc., can solve the problem of not fully removing the filter, and achieve the effect of simple detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

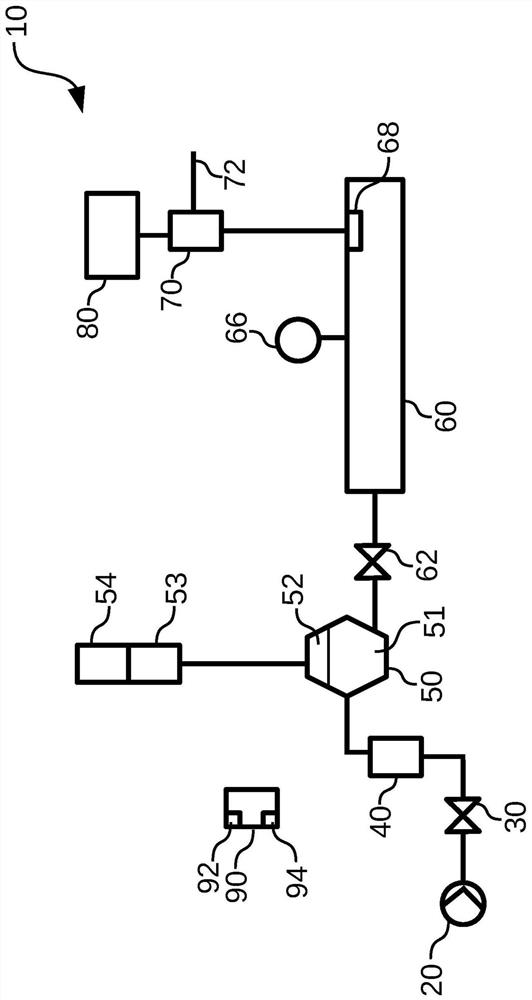

[0026] figure 1 A schematic diagram of one embodiment of a direct water injection system 10 according to the invention is shown.

[0027] The water direct injection system 10 includes a water pump 20 for pumping or delivering water, a filter 40 for filtering water, an air separator 50 and a high pressure pump 70 .

[0028] The direct water injection system 10 is designed to inject a fuel-water mixture into a combustion chamber of a motor vehicle. A motor vehicle can be a car, truck, passenger car, motorcycle, plane, train or ship. The temperature in the combustion chamber can be lowered by means of water, thereby increasing the power of the engine 80 . Furthermore, fuel consumption can be reduced in this way.

[0029] Between the water pump 20 and the filter 40 is provided a "tank cut-off valve" 30 for blocking the connection pipeline between the water pump 20 and the filter 40 . The filter 40 is provided between the tank shutoff valve 30 and the air separator 50 . The ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com