System and method for extracting water from a mechanical air conditioning system for water injection

A water injection and mechanical technology, applied in mechanical equipment, charging systems, air handling equipment, etc., can solve problems such as insufficient water injection requirements for engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

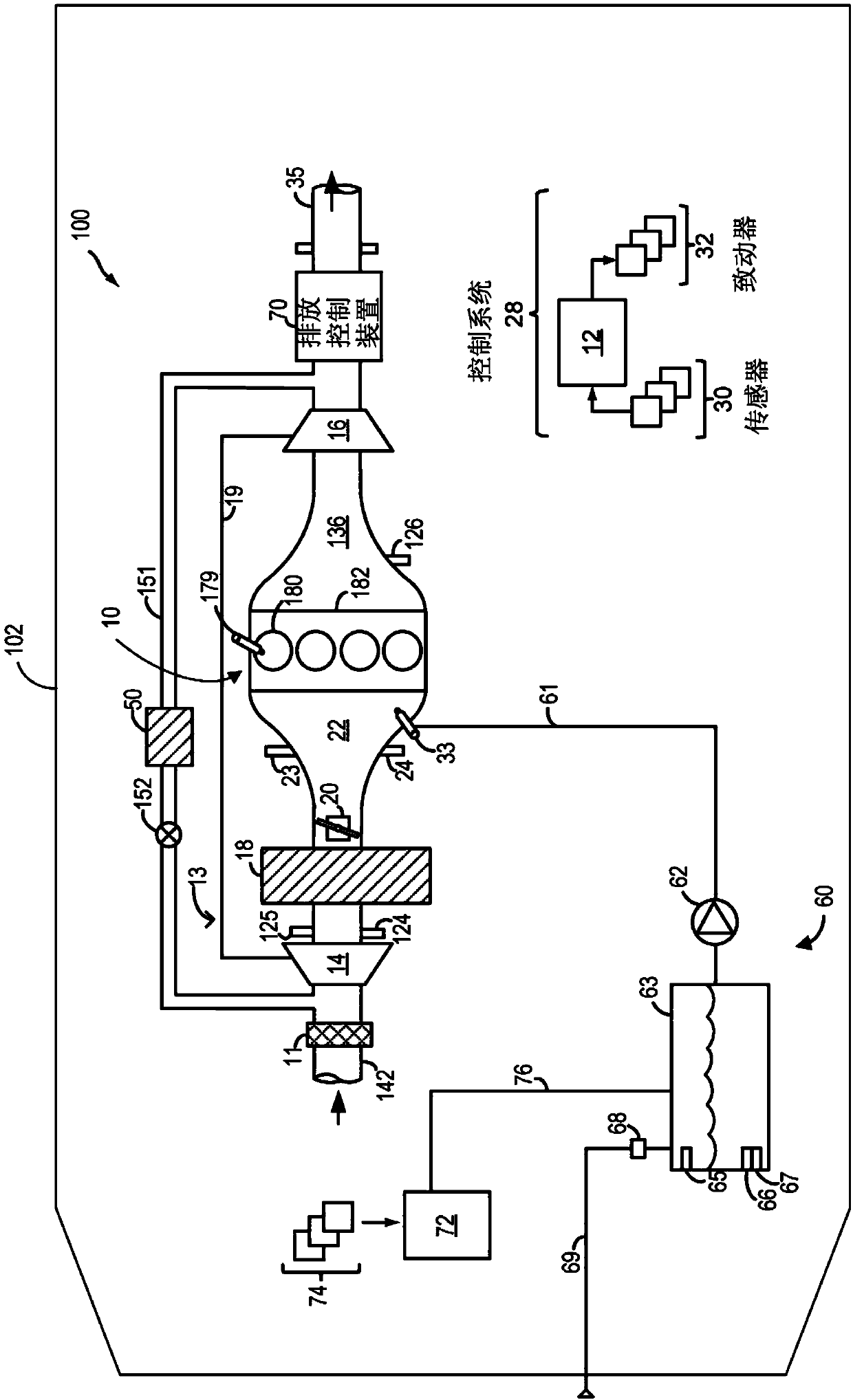

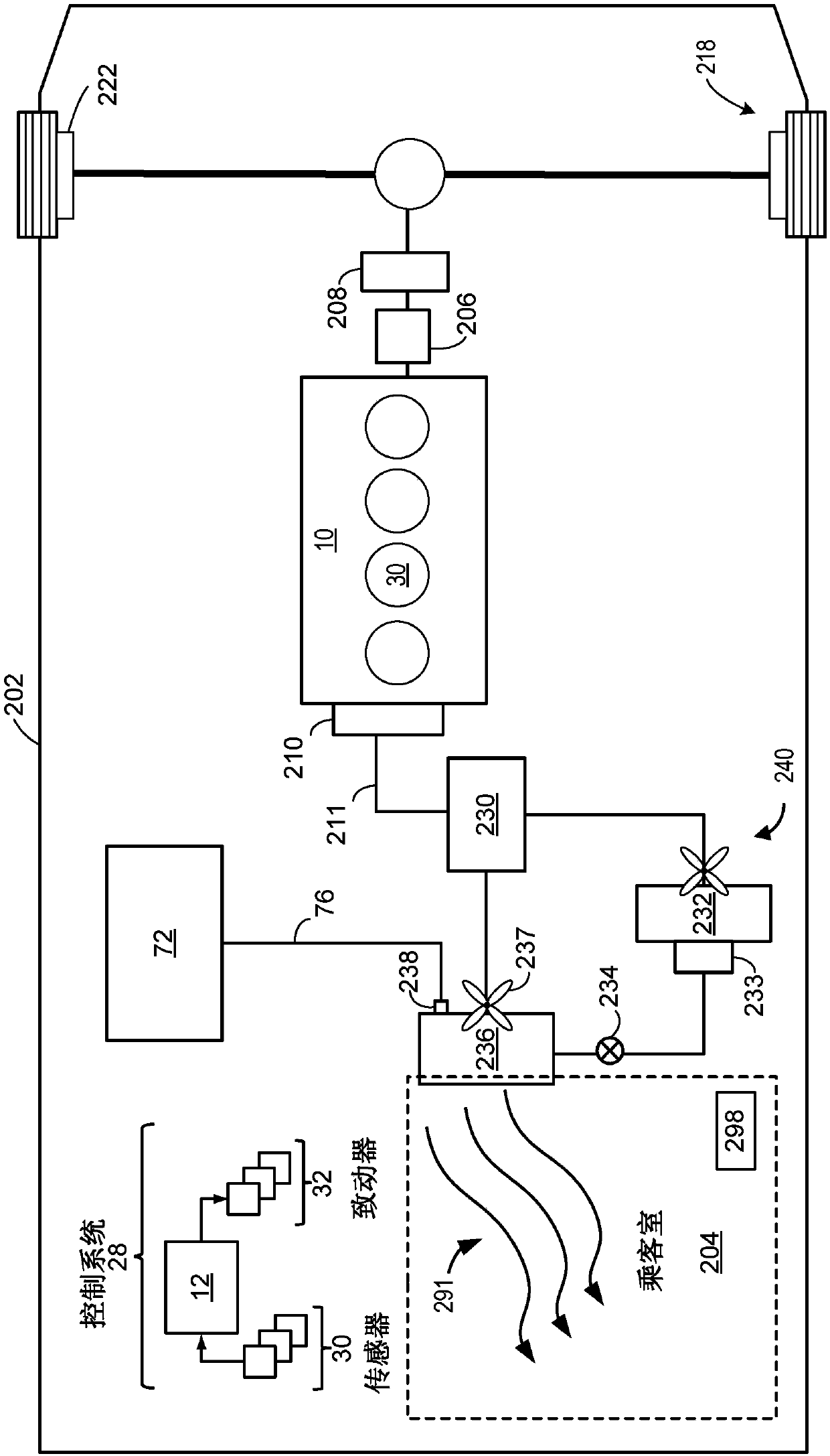

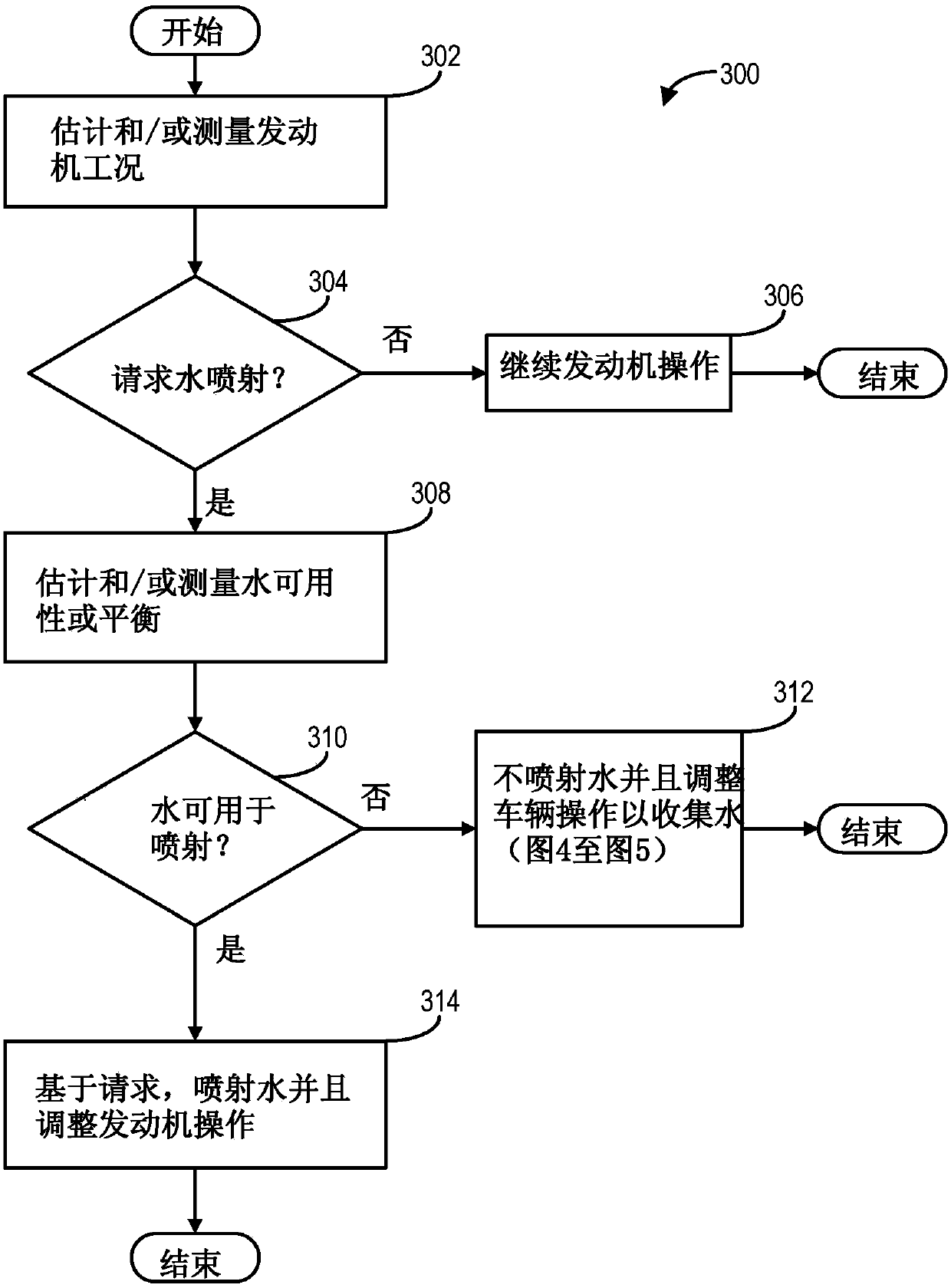

[0012] The following description relates to systems and methods for adjusting air conditioning (AC) compressor load and the amount of friction braking based on the water level in a water storage tank of a vehicle system. During a braking event, the amount of friction braking may be reduced and the AC compressor load in the mechanical AC system increased to collect water for injection into the engine and deliver the desired braking effort. The collected water may be stored in a water storage tank of the water collection system and then sprayed via one or more water injectors coupled to the engine. figure 1 A schematic diagram of an example engine system including a water collection system that receives collected condensate from an AC system and injects collected water into the engine is shown in . exist figure 2 , a schematic diagram of an example vehicle system is shown that includes a figure 1 Substantially the same engine system and water injection system are shown. also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com