High-position arrangement turboset auxiliary engine cooling water device based on pressure regulating water tank

A technology of auxiliary cooling water and pressure regulating water tank, applied in water shower coolers, machines/engines, steam/steam condensers, etc., can solve the problem that the design pressure should not be too high, the auxiliary cooling water pressure is poor, and the It can improve the safety reliability and automation level, improve the system pressure regulation speed, and ensure the automatic switching and stability effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

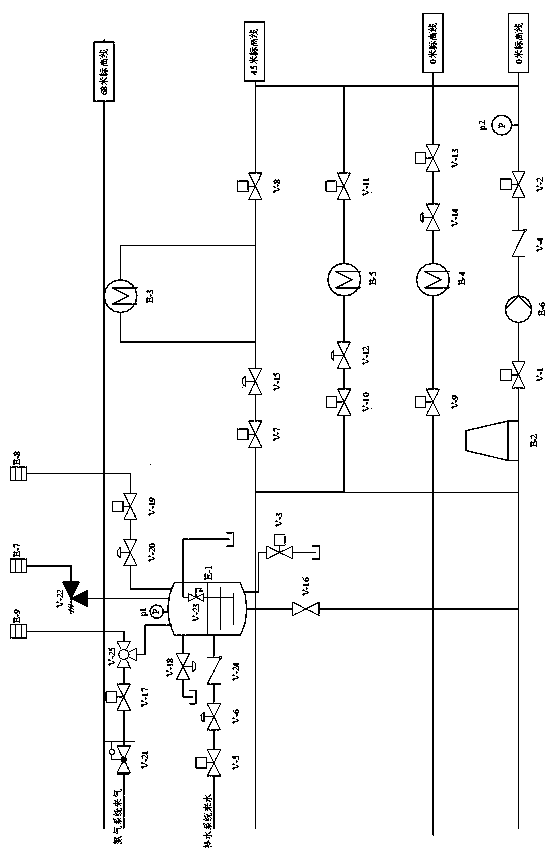

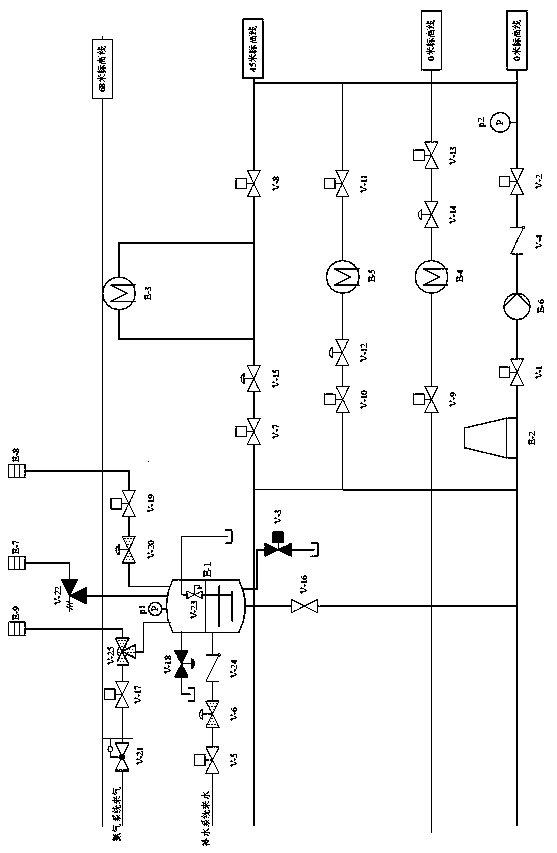

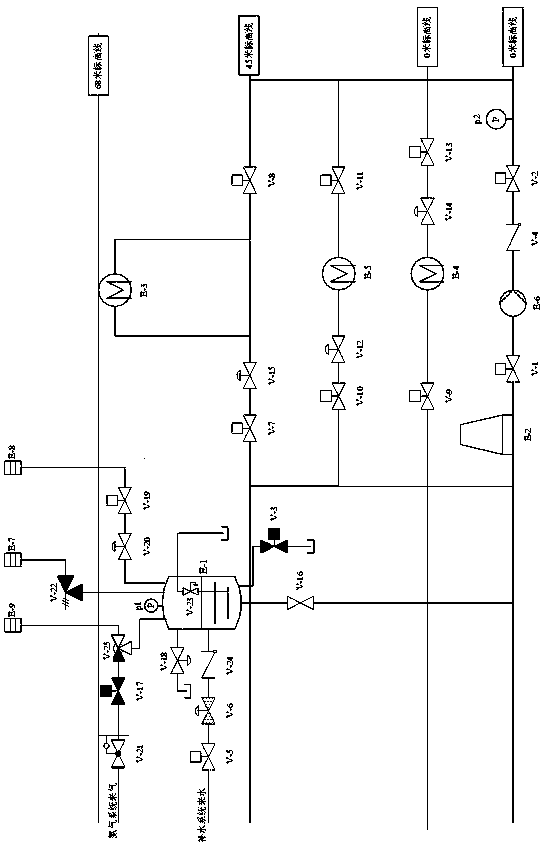

[0050] Attached below Figure 1-3 The present invention is further described in detail:

[0051] The invention includes an E-1 pressure regulating water tank, an air intake device installed on one side of the top of the E-1 pressure regulating water tank, an exhaust pressure maintaining device installed on the other side of the top of the E-1 pressure regulating water tank and a safety release device, the normal pressure overflow device installed on the upper side of the E-1 pressure regulating water tank, the V-23 drainage float valve installed in the E-1 pressure regulating water tank, and the water outlet device installed at the bottom of the E-1 pressure regulating water tank. The air intake device, the safety relief device and the exhaust pressure maintaining device are all connected to the muffler through pipelines; the muffler includes an E-9 silencer connected to the air intake device and an E -8 silencers.

[0052] The E-1 pressure regulating water tank is adopted, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com