Movable pouring type composite concrete pavement grouting equipment

A concrete pavement and pouring technology, which is applied in the direction of roads, roads, road repairs, etc., to achieve the effects of reducing costs, accurate ingredients, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention are provided below in conjunction with the accompanying drawings. The disclosed embodiments are only preferred embodiments of the present invention. Of course, the scope of the rights of the present invention cannot be limited by this. Therefore, the equivalent changes made according to the claims of the present invention , still falls within the scope of the present invention.

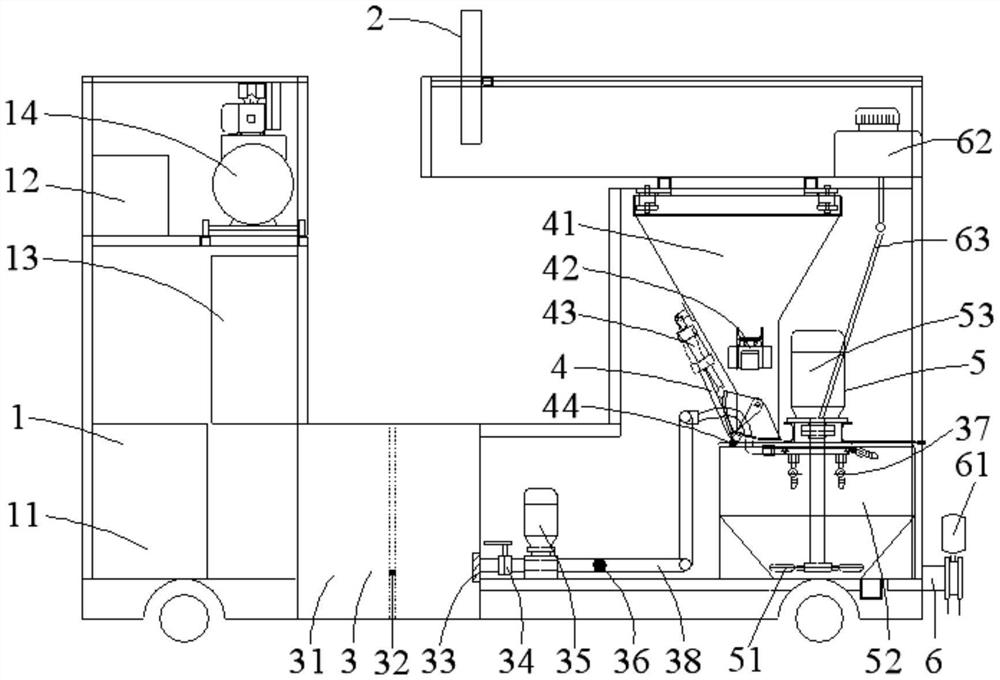

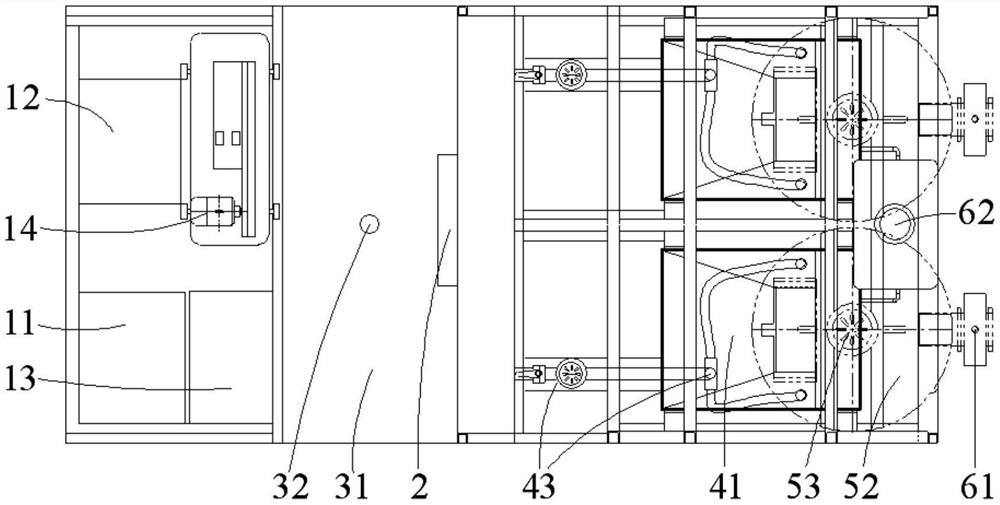

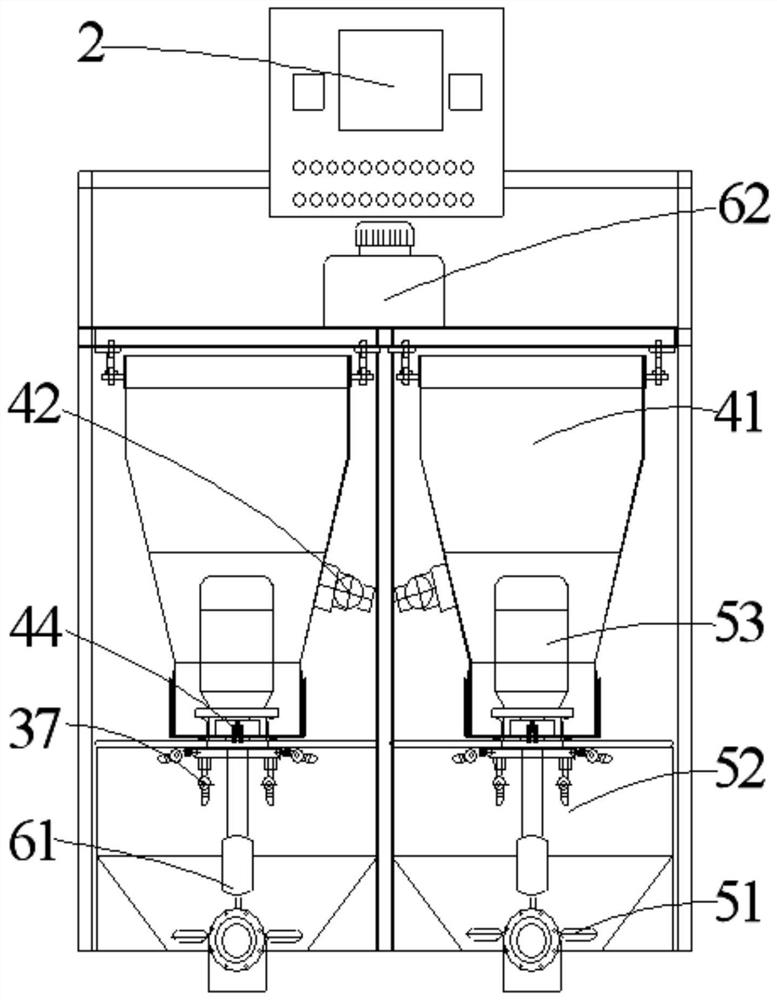

[0026] See Figure 1 to Figure 3 As shown in the figure, a movable pouring type composite concrete pavement grouting equipment disclosed in the present invention includes a PLC electrical control system 2 integrated on the traveling mechanism, a power system 1, an automatic water injection and cleaning system 3, and a dry material weighing system 4. , Mixing and stirring system 5 and automatic pulping system;

[0027] in,

[0028] The PLC electrical control system 2 is the central system, which is connected with the electrical signal of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com