Vehicle-mounted exhaust gas diesel oil reformer capable of preventing thermal oxidation coking problem

A reformer and thermal oxidation technology, applied in exhaust gas recirculation, oil supply device, exhaust device, etc., can solve the problems of fuel coking, affecting reformer performance, thermal oxidation coking, etc., to reduce oxygen content, achieve Multiple utilization to achieve the effect of deoxidation treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

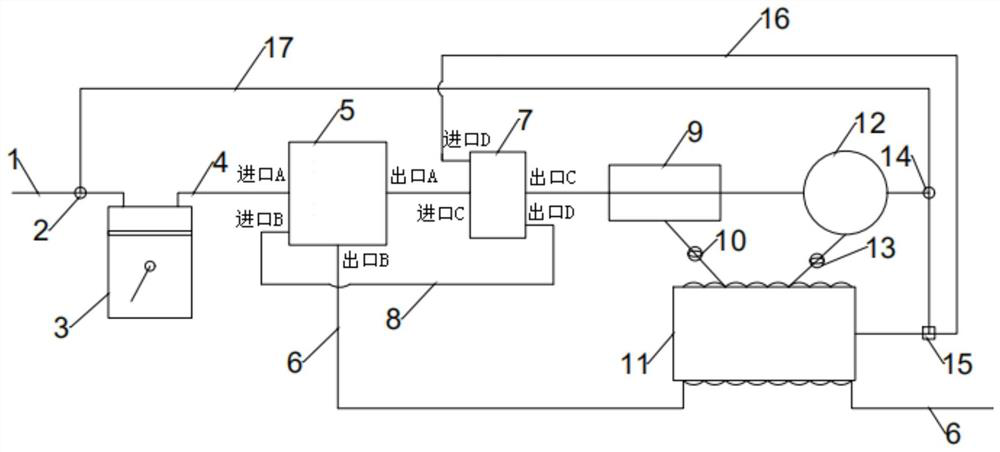

[0019] Such as figure 1 As shown, a vehicle-mounted exhaust gas diesel reformer for preventing thermal oxidation and coking problems proposed by the present invention includes an engine cylinder 3, a diesel engine post-processing device 5, an exhaust manifold 6, an OSC oxygen removal device 7, a regeneration exhaust pipe 8, Reforming water tank 9 , water injection pump 10 , reformer 11 , reforming oil tank 12 , regeneration air intake pipe 16 and return air pipe 17 .

[0020] The engine cylinder 3 is connected with an intake branch pipe 1 and an exhaust branch pipe 4, the intake branch pipe 1 is provided with a first three-way valve 2, and the first three-way valve 2 has two inlets; the diesel engine post-processing device 5 There are two inlets (inlet A, inlet B) and two out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com