Guide bar arrangement

A guide rail device and guide rail technology, which is applied in the direction of sawing equipment, chain saws, wood processing appliances, etc., can solve the problems of being easily blocked by sawdust or the like, hindering oil delivery to the saw chain, etc., and achieve the goal of improving lubrication and reducing demand Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

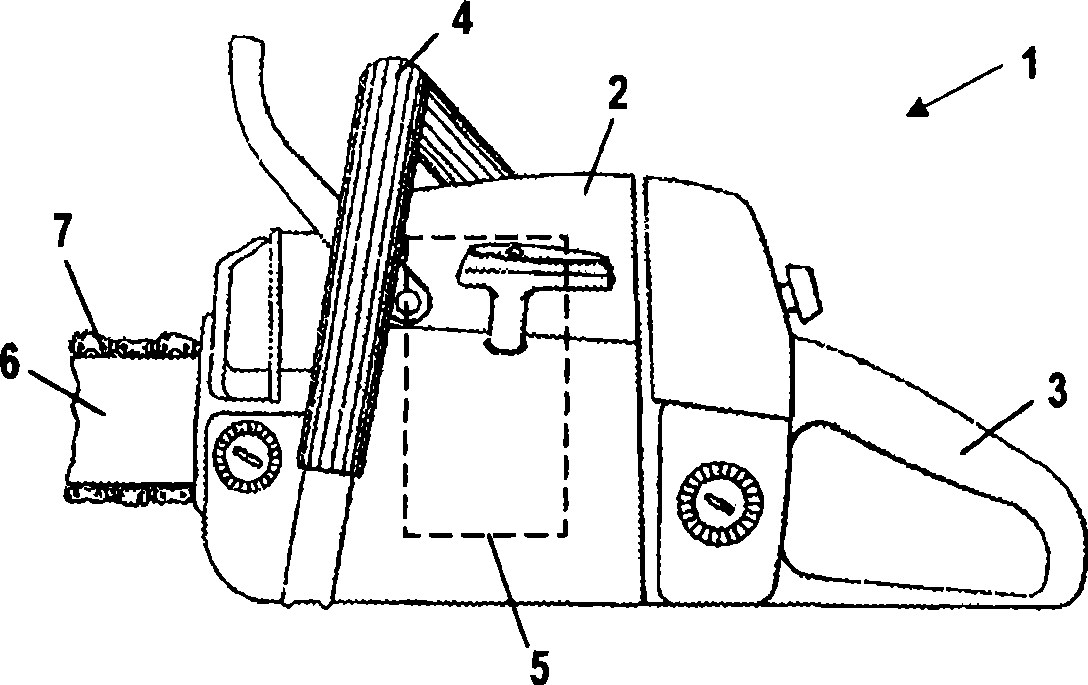

[0023] exist figure 1 An exemplary embodiment of a hand-operated hand-held power saw 1 is shown in FIG. 1 , but the invention can also be used in other power saws, such as high branch saws (Hochentaster), or harvesters, so-called harvesters.

[0024] The power saw 1 has a housing 2 . A rear handle 3 and an operating tube 4 are fixed on the housing. On the side of the housing 2 opposite the rear handle 3 a guide rail 6 protrudes forward. A saw chain 7 is arranged circumferentially on the guide rail. A drive motor 5 is arranged in the housing 2 . This motor drives the saw chain 7 around the guide rail 6 .

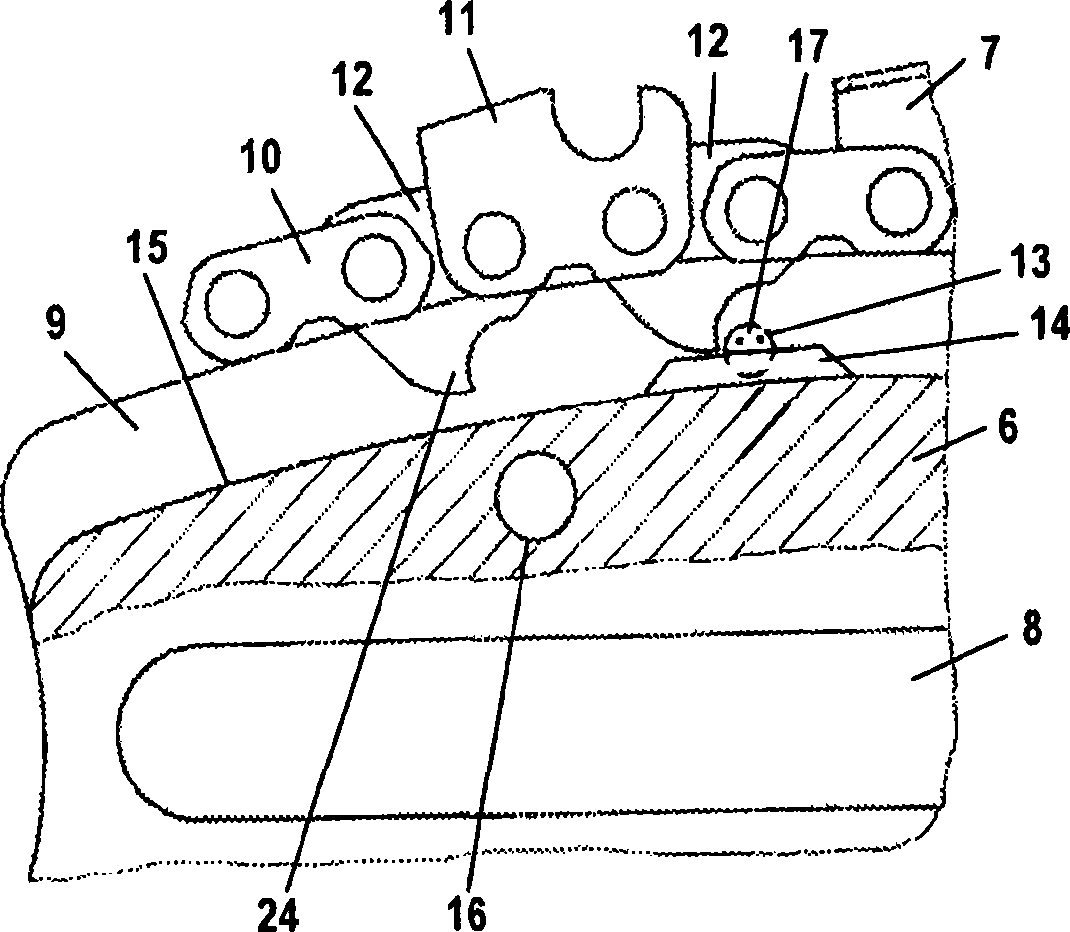

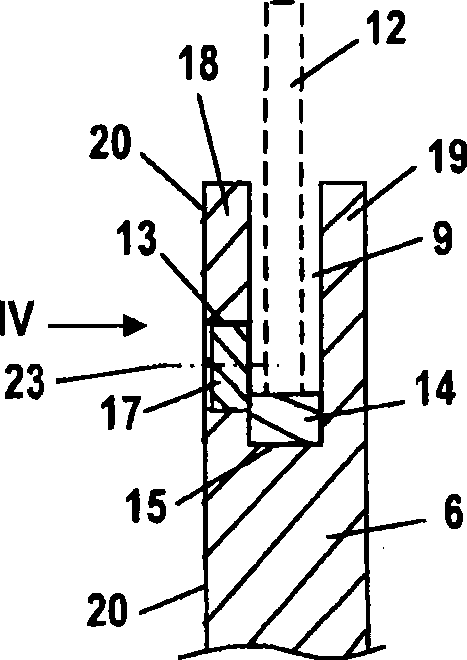

[0025] exist figure 2 A cross-sectional view of the region of the guide rail 6 fastened to the power saw 1 is shown in . In order to fix on the power saw 1 the guide rail 6 has a longitudinal groove 8, and some transverse holes 16, in the figure 2 Only one of the holes is shown. A tensioning device (not shown) for the saw chain 7 can engage in this transverse hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com