A surface defect detection method, terminal equipment and storage medium

A defect detection and defect technology, applied in image analysis, image enhancement, instruments, etc., can solve problems such as inability to achieve defect contour segmentation, inappropriate detection objects and defect types, and raising the threshold for monitoring system development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

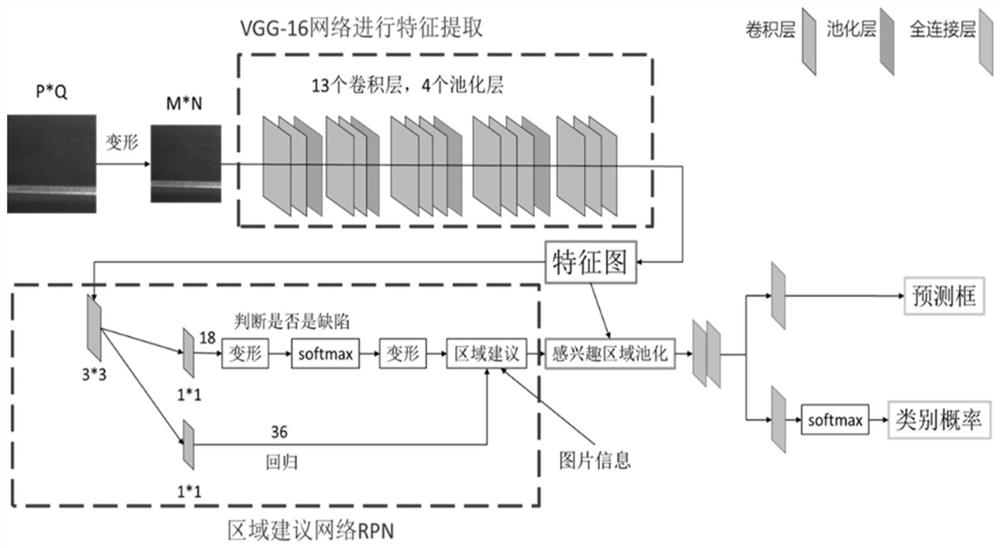

[0057] The present invention provides a surface defect detection method, which is implemented based on the improved Faster R-CNN network. This embodiment uses the surface defect detection just now as an example to illustrate. In other embodiments, this method can also be applied to other items in the detection of surface defects.

[0058] The method described in this embodiment comprises the following steps:

[0059] Step 1: Collect defect images on the steel surface to form a training set, and label the defect images in the training set, and the labels include defect types and defect location frames.

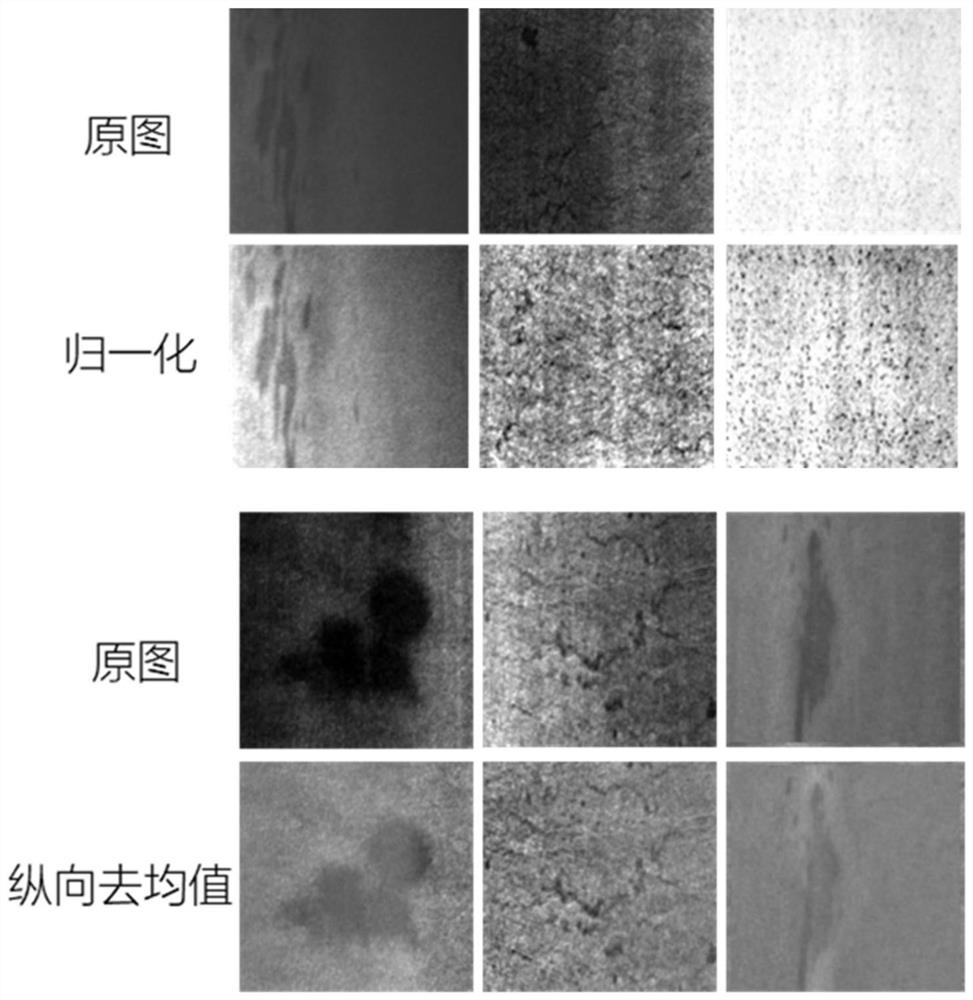

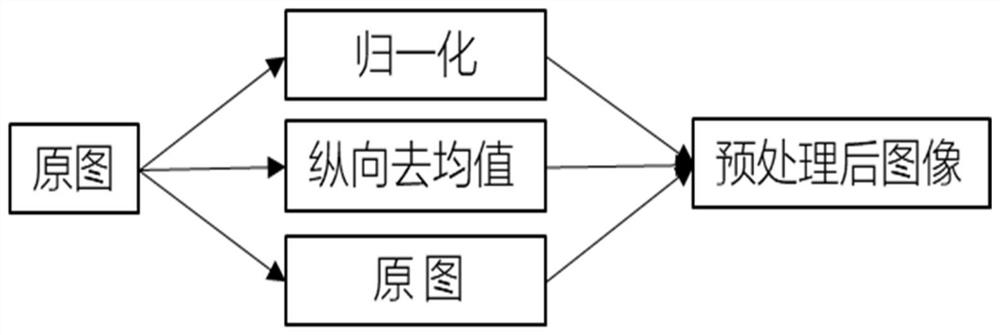

[0060] Furthermore, because the collected defect images not only have obvious light and dark differences globally, but also have huge differences in left and right lighting. Therefore, this embodiment also includes preprocessing the collected defect images. Specifically, two image processing methods are mainly used on the initial image:

[0061] The first one is to normalize...

Embodiment 2

[0172] The present invention also provides a surface defect detection terminal device, including a memory, a processor, and a computer program stored in the memory and operable on the processor, and the present invention is realized when the processor executes the computer program Steps in the above method embodiment of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com