Mobile terminal

A technology for mobile terminals and drive motors, applied in TV, color TV, telephone communication, etc., can solve the problem of poor shooting effect, achieve the effect of improving flexibility of use, improving shooting performance, and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

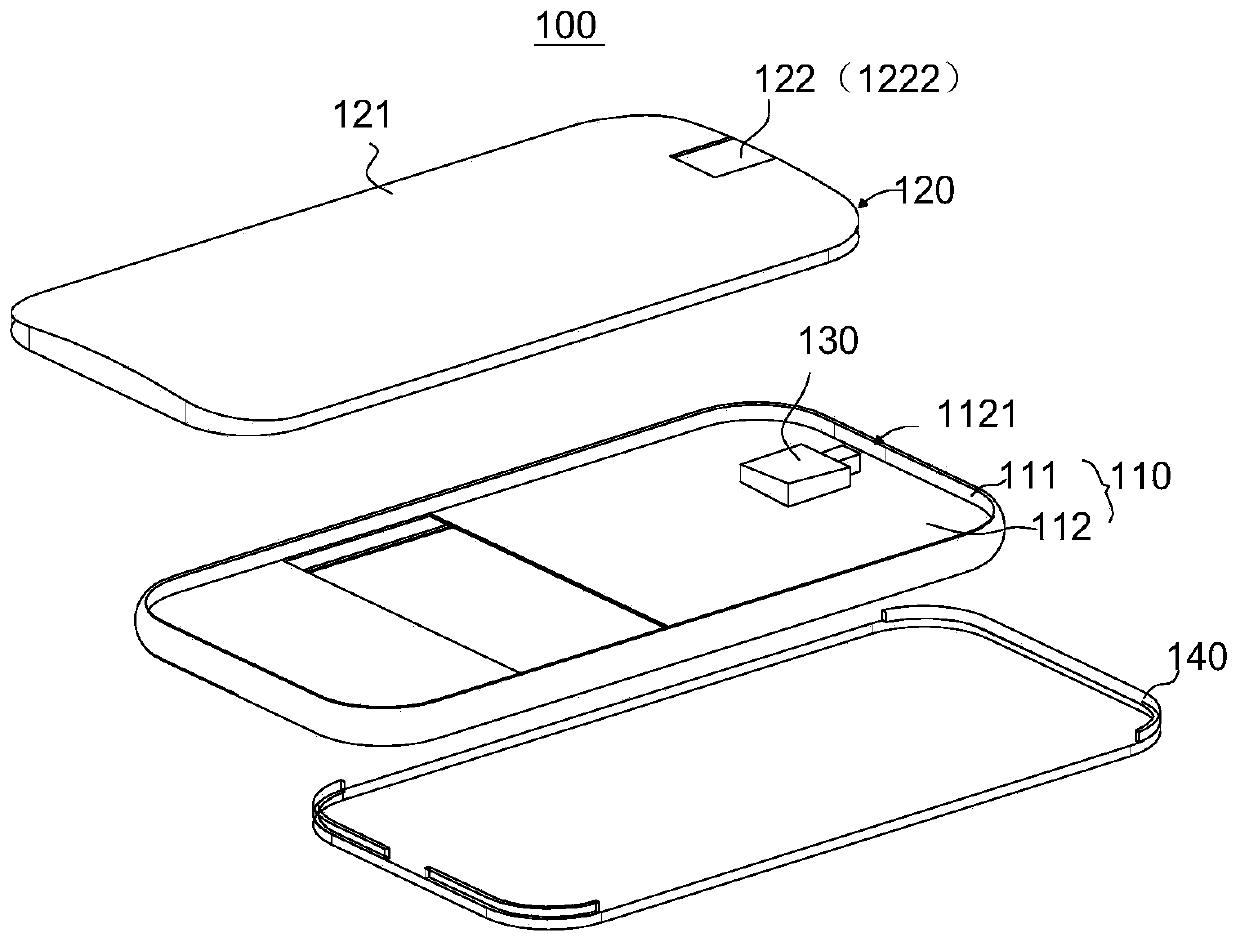

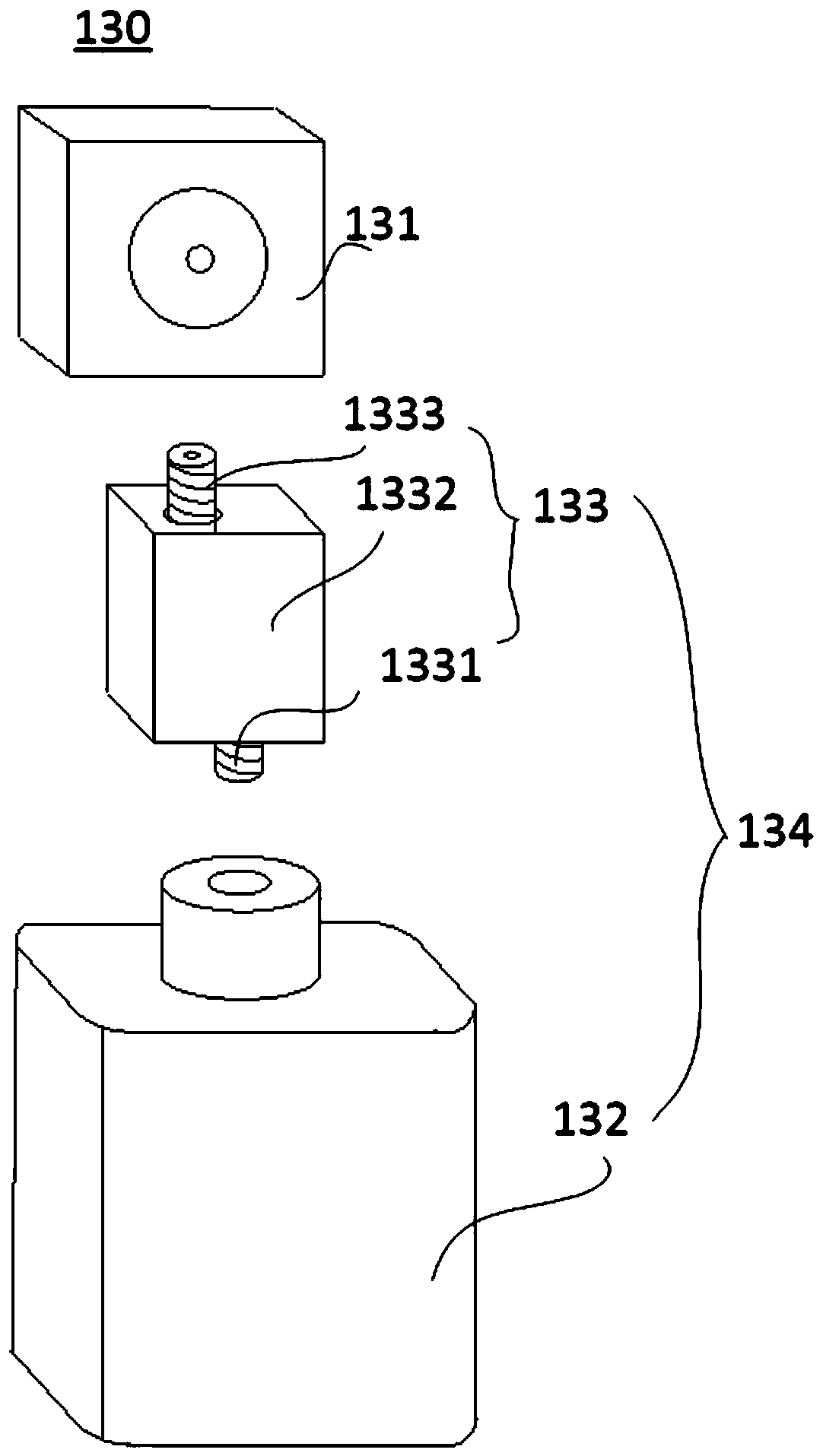

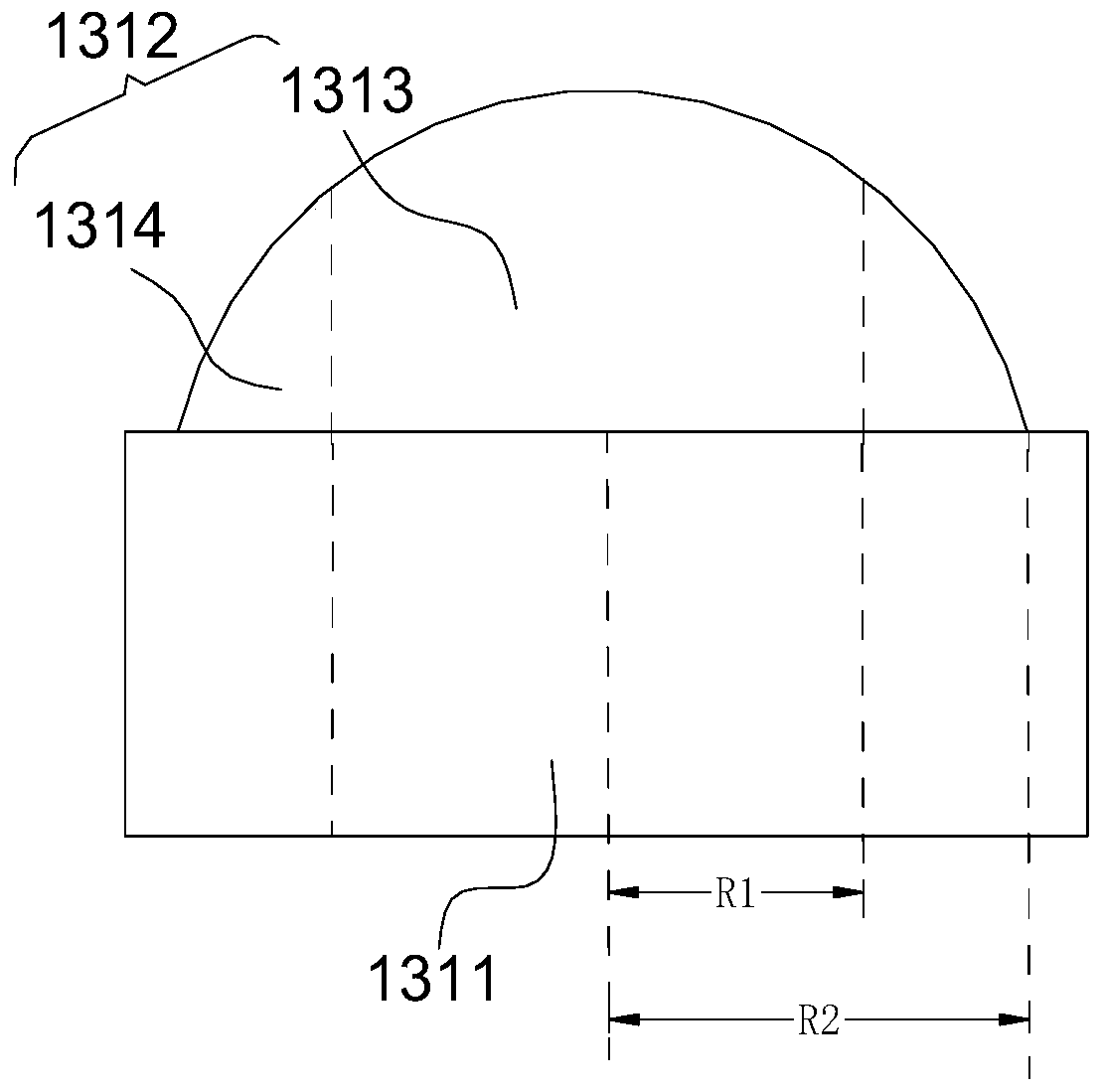

[0018] In order to enable those skilled in the art to better understand the solutions of the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

[0019] With the rapid improvement of the performance of mobile terminals, users have higher and higher requirements for mobile terminal functions, especially in terms of shooting performance. In order to allow users to use mobile terminals for panoramic shooting or large-angle shooting, at least one wide-angle lens is usually configured on the mobile terminal. Since the front lens of the wide-angle lens is usually spherical, its lens surface is raised relative to the mobile terminal shell, so it is prone to wear and tear. . Therefore, it is usually necessary to install a protective glass outside the wide-angle lens of the mobile terminal to protect the wide-angle glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com